9

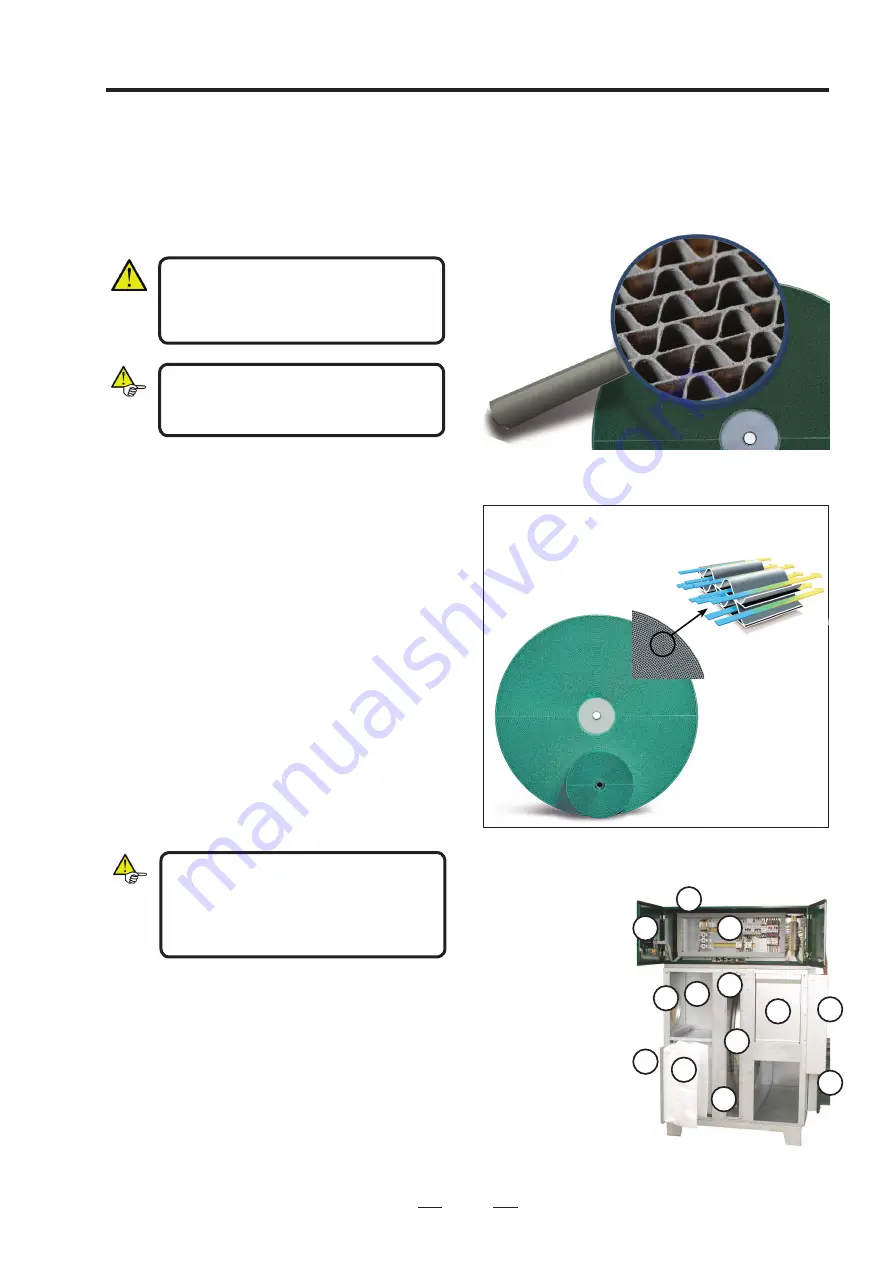

FIGURE 2: Rotor matrix

3 Design

The unit should be electrically isolated

before dismantling. The main switch

should be in position "0", and can be

locked in this position.

If the unit has been in operation, wait until

the regeneration fan has stopped before

disconnecting and dismantling the unit.

The unit is designed so that it easily can

be lifted by a fork lift. To allow securing

of the unit to the floor or to a pedestal,

square washers are delivered with the

unit.

1. Electric equipment

2. Rotor

3. Rotor motor

4. Reg filter

5. Process filters

6. Process fan

7. Reg. fan, behind

electric cabinet

8. Regen. heater

9. Process air in

10. Dry air out

11. Regen. air in

12. By-pass

13. Wet air out, behind

electric cabinet

1

2

6

10

11

3

8

7

5

9

12

4

13

Section of a dehumidifier rotor from Seibu Giken.

The high number of channels means that mois-

ture is adsorbed with extra

efficiency!

FIGURE 3: Principle function of the rotor

FIGURE 4: Principle of design

high capacity for adsorbing water vapour. It has a

galvanized sheet metal lining, spokes and a hub and

two bearings on which it rotates around a fixed steel

shaft.

3.1 Housing and dismantling

The RECUSORB RZ dehumidifier has a housing

of galvanized sheet metal (AlZn). The unit housing

contains rotor, rotor motor with belt transmission,

regeneration heater and filters. The fans and the

electrical control equipment are placed externally on

the unit.

The regeneration fan removes residual heat from the

regeneration heater for ten minutes after the unit has

been switched off.

The access panel at the front of the unit can easily be

opened, to enable service and inspection. The panels

can be opened without any tools as they are fixed with

hand wheels.

The rotor unit is located between the two panel doors

at the front. It contains rotor, rotor transmission and

rotor motor. The short side of the rotor unit has a

polycarbonate access panel, which is screwed to the

rotor unit. The panel is removed to gain access to the

rotor and the rotor transmission. The rotor motor can

be reached when the left hand panel door is opened.

The electric box with control panel and all electric

equipment is located on the top of the unit. The lids

of the electric box can be opened when the lock are

turned with a key that is attached with the unit.

The air connections are round galvanized spigots in

standard dimensions.

3.2 Rotor

The heart of a DST dehumidifier is the very efficient

patented SSCR silica gel rotor. The rotor matrix

is manufactured from alternate layers of flat and

corrugated sheets of silica gel and metal silicates,

chemically bonded into a tissue of inorganic fibres. It

is made to form a vast number of axial air channels

running parallel through the structure. The large

internal surface area combined with the special micro

structure of the SSCR silica gel material, ensures

maximum contact area to give the rotor an extremely

Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz