TDAS G5 DAS

User’s Manual

October 2019

5

11000-00010-MAN (Rev. 5)

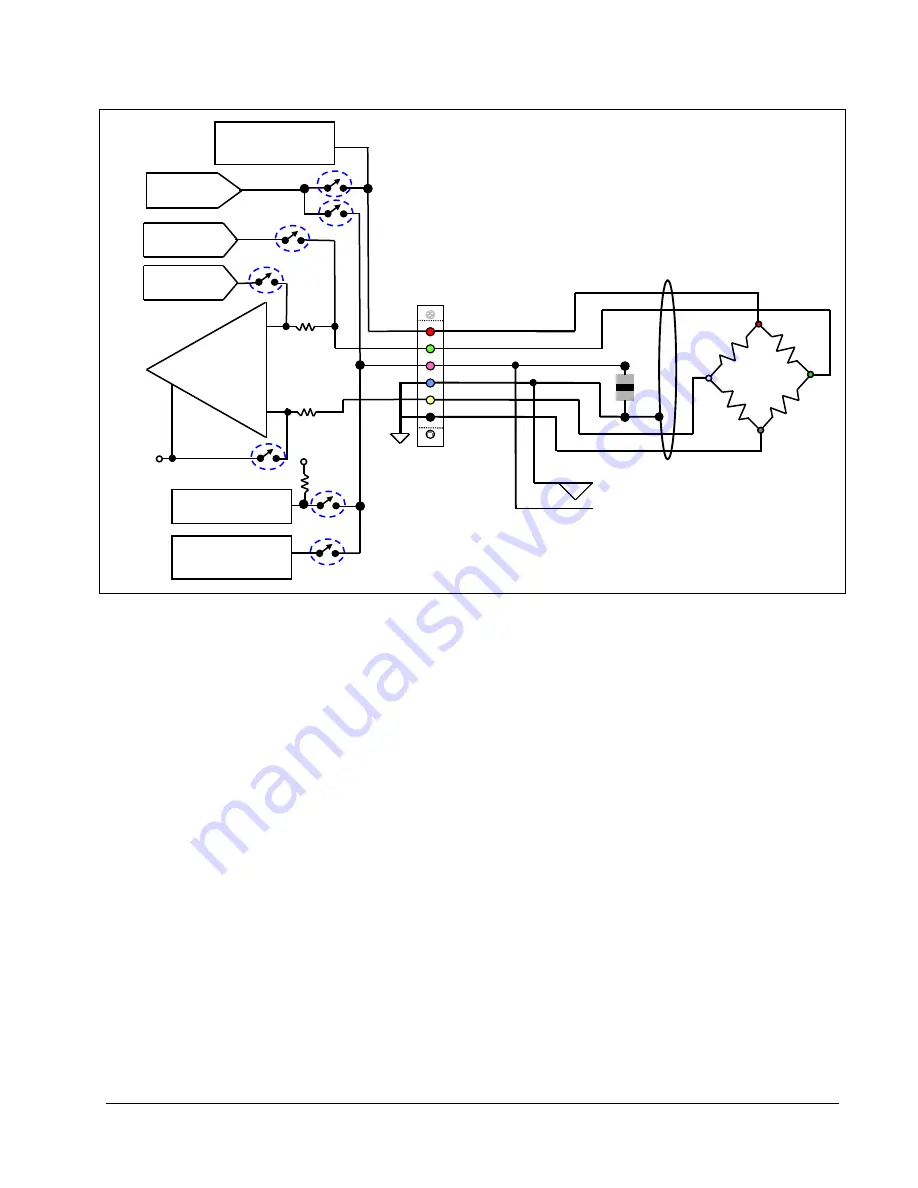

Sensor Connections

Shunt Calibration Resistors

Conventional shunt calibration resistors are not supported in the TDAS G5 DAS. Shunt

emulation is used to perform shunt checks.

Shunt Emulation

The TDAS G5 DAS uses shunt emulation to perform shunt checks. Shunt emulation

eliminates the need for conventional shunt resistors and is enabled when “Emulation” is

chosen in the SIF as the shunt calibration method. This method applies a precise current

to a connected sensor and checks for expected deflection based on sensor impedance.

Shunt checks are performed under software control; settings are calculated by the

software and the applied shunt signal is automatically scaled to an appropriate

percentage of the requested range. (See the TDAS Control software manual for

additional information.)

It is always best to complete the bridge when using half-bridge sensors. We recommend

completing the bridge with fixed resistors on the +Sig side, then using the value of the

fixed resistors for shunt emulation.

guide pin

Shield

-Ex

ID/digital

+Ex

+Sig

-Sig

+Ex

+Sig

-Sig

R

R

R

R

-Ex

Dallas ID

Differential

Instrumentation

Amplifier

2.5 V

Ref

Excitation

5 V, 20 mA

Gain

Calibration

Excitation

Check ADC

Dallas ID

Interface

Digital Inputs

+5 V

-

+

TDAS G5 DAS

Sensor

Connector

Contact Closure

Shunt Check

Driver

2004-2019

©

Diversified Technical Systems, Inc. - All Rights Reserved