7

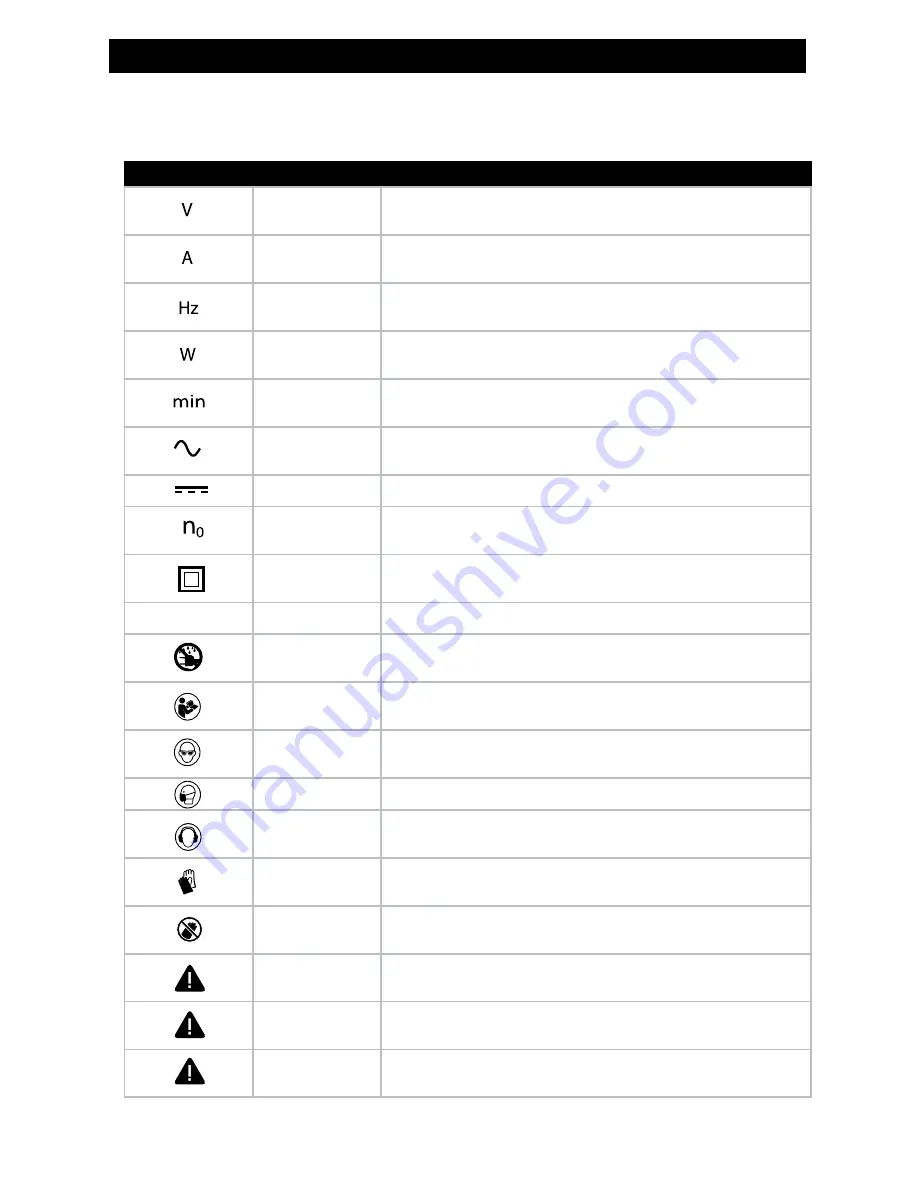

SYMBOLS

Some of the following symbols may be used on this tool. Proper interpretation of

these symbols will allow you to operate the tool better and safer.

SYMBOL

NAME

DESIGNATION/EXPLANATION

Volts

Voltage

Amperes

Current

Hertz

Frequency

Watt

Power

Minutes

Time

Alternating

Current

Type of Current

Direct Current

Type of Current

No Load

Speed

Rotational speed at no load

Class II

Construction

Double‑insulated construction

RPM

Per Minute

Revolutions per minute

Wet Conditions

Alert

Do not expose to rain or use in damp areas.

Read User

Manual

To reduce the risk of injury, user must read and understand

user’s manual before using the product.

Eye Protection

Always wear safety goggles or safety glasses with side

shields.

Face Mask

Wear full‑face mask when operating this product.

Ear Protection

To protect your ears from noise, always wear ear

protectors or ear plugs.

Gloves

Always wear gloves when operating this product.

No Hands

Symbol

Failure to keep your hands away from the rotating pads

may result in serious injury.

Danger

Indicates an immediate hazardous situation. Must avoid to

prevent death or serious injury.

Warning

Indicates a potentially hazardous situation, which, if not

avoided may result in serious injury.

Caution

Indicates a potentially hazardous situation, which, if not

avoided may result in minor injury.

Summary of Contents for PS7000

Page 19: ...18 PARTS LIST ...