Safety measures

Assembly and disassembly must be performed by operators who have been trained in

assembly and security instructions.

Only use parts in good condition we have manufactured and referenced in the nomenclature.

Make sure the assembly is compliant with the user guide.

For any use not compliant to the user guide, please contact the manufacturer.

Before going on the scaffolding, please check that stabilizers are tightened and wheels locked.

Check that all the parts are pinned and that security features are locked.

During assembly and disassembly, you must wear Personal Protective Equipment, such as:

hard hat, safety shoes, gloves…

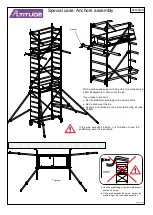

Respect the assembly order described in this user guide to the letter.

Anchor the scaffolding to a building or any other surface that can bear the stress.

Anchor the scaffolding on the top part at the end of each operation.

Horizontal forces must not exceed 30 kg

on the last floor level.

According to the current regulation, the

space between two floors cannot exceed

3m.

Maximum force: 30kg

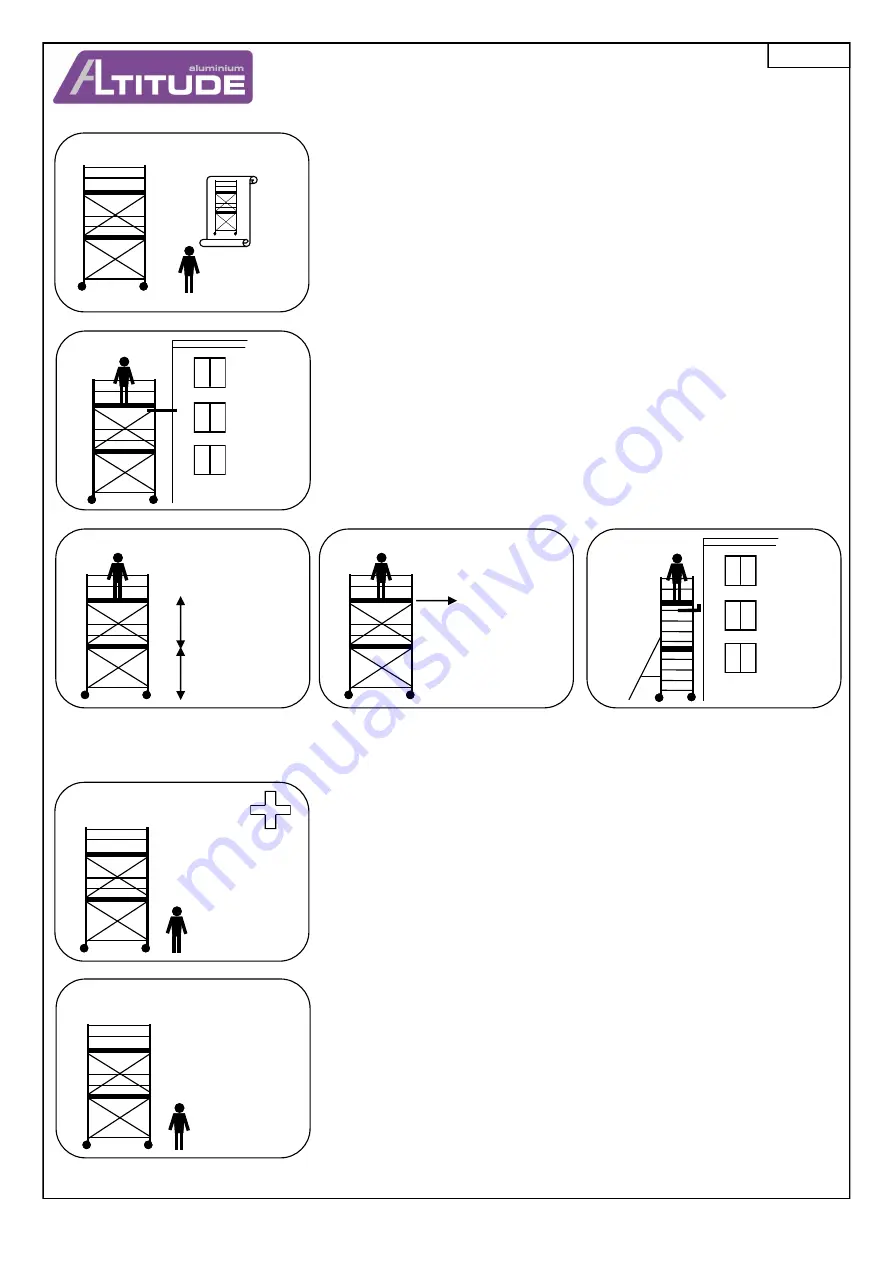

MAINTENANCE:

Before any assembly or use, you must check all the parts of the scaffolding to see if any could be

defective and replace it, if necessary.

You must make sure that:

Wheel treads and their brakes work properly.

All lock mechanisms (base body, handrails, diagonal braces) work properly.

The plywood of the floor and the trapdoor are in good condition.

DISASSEMBLY:

Before any disassembly, check that the wheels are locked and stabilizers are firmly tightened.

For the disassembly, respect the reverse assembly order described in this user guide to the

letter.

Disassemble them gradually to operate with maximum security.

When working on the front of the building,

use stabilizers and add 2 support bars.

OK

OK

OK

3

m

m

a

x

3

m

m

a

x

OK

OK

OK

Page 20/20

OK

D040369B