20

9.4

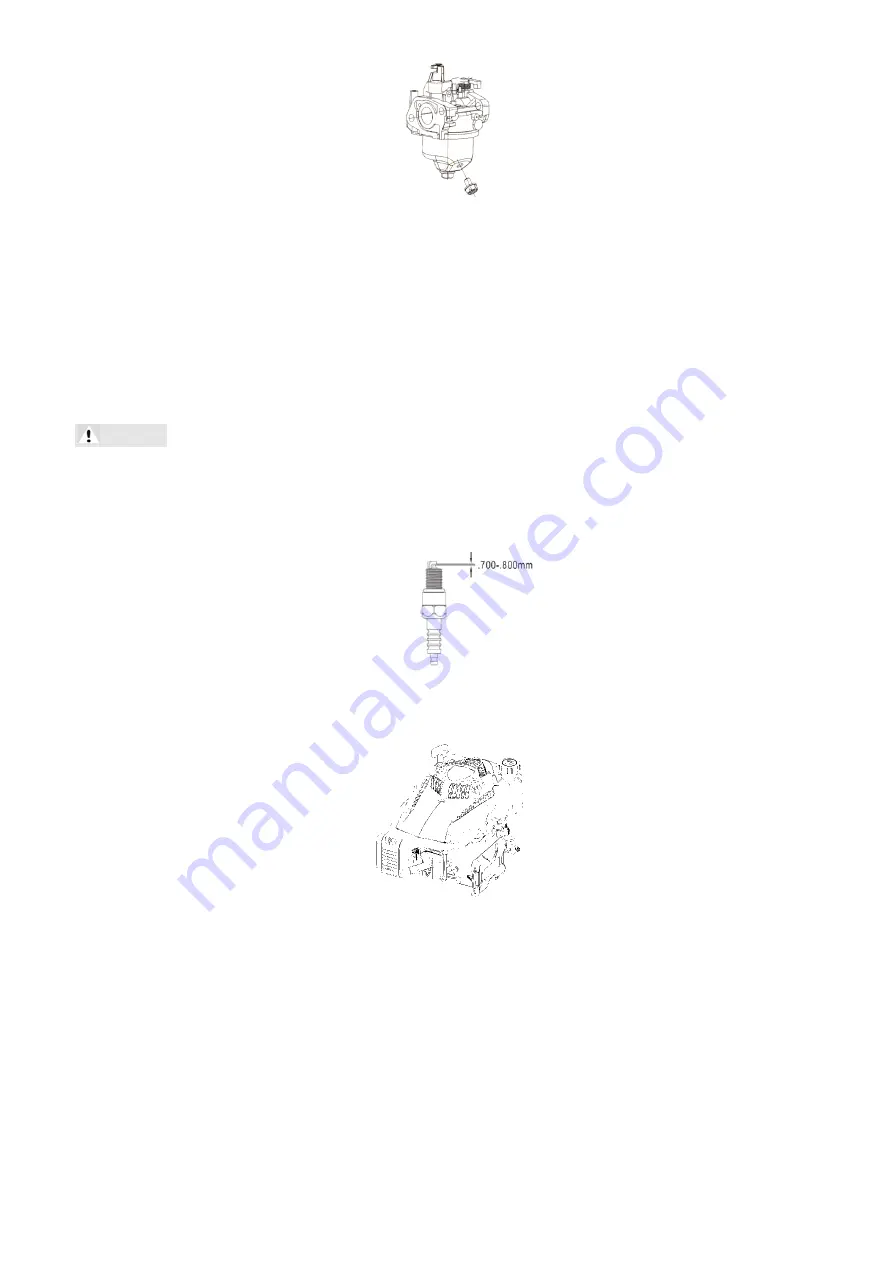

Spark

plug

service

Recommended

spark

plug:

BPR5ES

(NGK)

F7RTC

(LG)

To

ensure

proper

engine

operation,

the

spark

plug

must

be

properly

gapped

and

free

of

deposits.

1)

Remove

the

spark

plug

cap.

WARNING

If

the

engine

has

been

running

the

muffler

will

be

very

hot.

Be

careful

not

to

touch

the

muffler.

2)

Visually

inspect

the

spark

plug.

Discard

it

if

the

insulator

is

cracked

or

chipped.

3)

Measure

the

plug

gap

with

a

feeler

gauge.

The

gap

should

be

0.7

‐

0.8mm

(0.028

‐

0.031

in),

Correct

as

necessary

by

bending

the

side

electrode.

4)

Attach

the

plug

washer,

thread

the

plug

in

by

hand

to

prevent

cross

‐

threading.

5)

When

mounting

a

new

spark

plug,

you

should

screw

1/2

more

thread

with

the

wrench

after

the

washer

is

compressed.

If

you

are

mounting

an

old

one,

you

should

only

screw

1/8

‐

1/4

more

thread.

CAUTION:

The

spark

plug

must

be

securely

tightened.

An

improperly

tightened

plug

can

become

very

hot

and

possibly

damage

the

engine.

Never

use

a

spark

plug

with

an

improper

heat

range.

Summary of Contents for DT36V

Page 2: ......