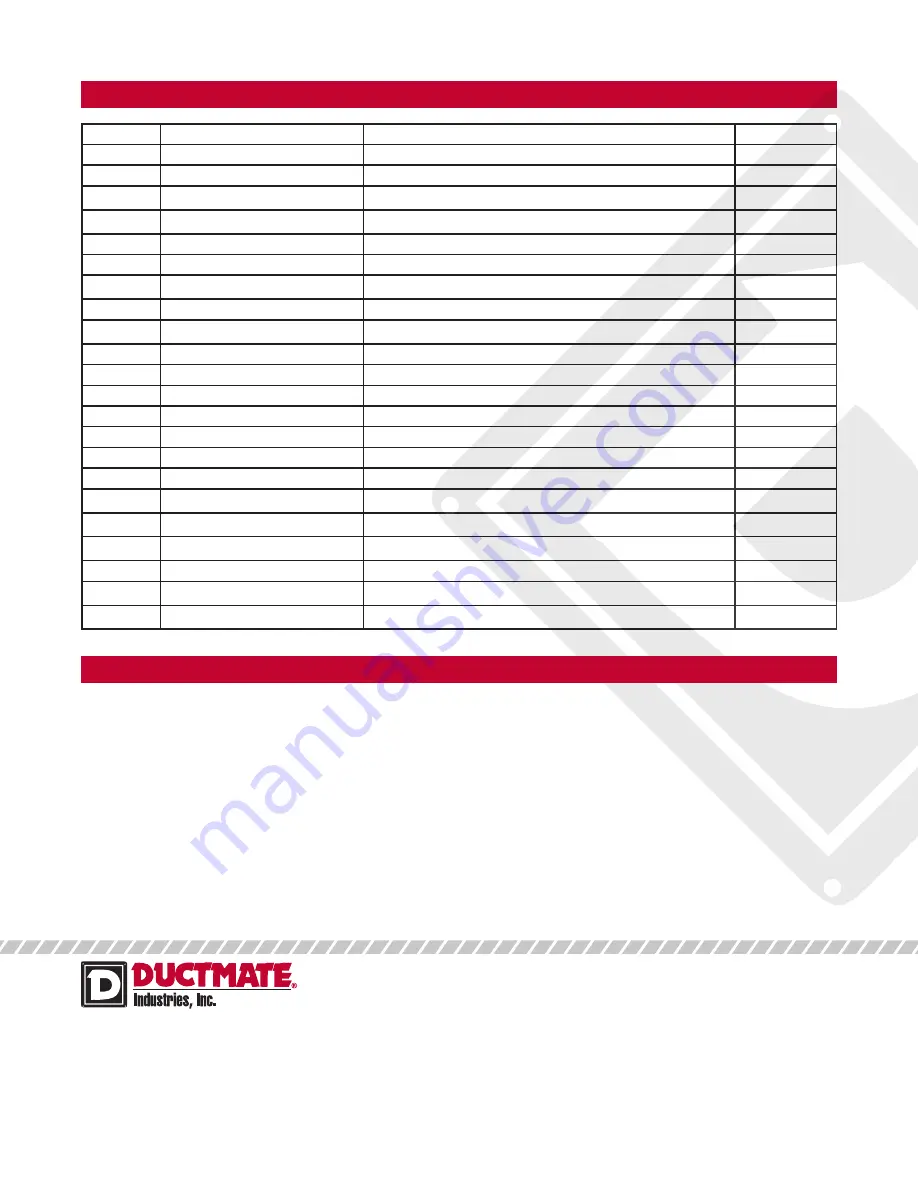

12.

Item #

Part #

Description

Quantity

1

R1002-06

CYL ROD CLEVIS KIT

1

2

R1002-05

AIR CYLINDER

1

3

RW1043-04

5/32" PUSH CONN. 1/8" NPT THD

1

4

SCREW SHL 3/8-3

3/8" x 2" SHOLDER SCREW

1

5

REPEATER 4200 S

REPEATER 4200 SPACER

2

6

SHCS M6X30

BOLT M6 x 30

4

7

REPEATER 4200 B

FLANGE BEARING 3/8" x 5/8" x 1/2"

2

8

RP1013

TOGGLE CLAMP WELDED

1

9

LOCKNUT NY 5/16

5/16" NYLON LOCKNUT

2

10

CORNERPR1006

10-24 MACHINE SCREW NUT

2

11

SBH 10-24X3/4

10-24 BUTTON HEAD CAP SCREW

2

12

REPEATER 4200 H

HANDLE WELDED

1

13

R1002-13

HANDLE GRIP

1

14

R1002-01

10/32" TAC VALVE

1

15

R1002-02

10/32" UNIV. ELBOW

1

16

REPEATER 4200 F

REPEATER 4200 FRAME ASSEMBLY

1

17

SCREW SHL 3/8-2

3/8" x 1-1/4" SHOLDER SCREW

1

18

RW1045

5/32" PUSH CONN. 10-32 THD

2

19

RW1043-02

5/32" PUSH CONN. 1/4" NPT THD

1

20

RW1044

1/4" NPT STREET RUN TEE

1

N/A

RW1048

5/32"OD POLYFLO TUBING

2.5 ft

N/A

R1002-09-1

1/4" OD POLYFLO TUBING

2.5 ft

P A R T L I S T R E P E A T E R 4 2 0 0 F R A M E C o n t .

Charleroi, PA

210 Fifth Street

Charleroi, PA 15022

800-245-3188

724-258-0500

FAX: 724-258-5494

Lodi, CA

810 S. Cluff Avenue

Lodi, CA 95240-9141

800-245-3188

724-258-0500

FAX: 209-333-4678

www.ductmate.com

704 - 11/13

Ductmate warrants that the Repeater 4200, when properly installed and maintained, will be free from defects in material and workmanship,

and will comply with all written specifications made by Ductmate at the time of sale. Ductmate’s warranty shall run for a period of one year

from the date of manufacture.

Warranty Limitation

The warranty stated above is in lieu of all other warranties, express or implied, including but not limited to the implied warranties of

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Although Ductmate may have suggested the product, or provided

written or oral advice to the Purchaser, it is the Purchaser’s responsibility to test and determine the suitability of the Repeater 4200, for the

intended use and purpose, and Purchaser and/or its customer assumes all risk and liability whatsoever regarding such suitability.

Limitation of Liability

In the event of a breach of the above warranty, Ductmate’s sole obligation, and Purchaser’s sole and exclusive remedy, shall be, at Ductmate’s

option, repair or replacement of any defective products, or refund of an applicable portion of the purchase price. Ductmate shall have no

liability for costs of removal or reinstallation of the product. The Purchaser agrees that no other remedy, including but not limited to loss of

profits, loss sales, injury to person or property, or any other special, incidental or consequential damages, shall be available to the Purchaser

for any claim arising out of this Agreement, regardless of whether such claim is made in contract or in tort, including strict liability in tort. In no

event will Ductmate be obligated to pay damages to the Purchaser in any amount exceeding the purchase price that the Purchaser paid to

Ductmate for the allegedly defective product.

L I M I T E D P R O D U C T W A R R A N T Y