4

IT IS NECESSARY THAT ALL THE OPERATIONS REGARDING THE INSTALLATION, ADJUSTMENT

AND ADAPTATION TO THE TYPE OF GAS AVAILABLE ARE CARRIED OUT BY QUALIFIED

PERSONNEL, IN CONFORMITY WITH THE REGULATIONS IN FORCE.

THE SPECIFIC INSTRUCTIONS ARE DESCRIBED IN THE BOOKLET SECTION

INTENDED FOR THE INSTALLER

INSTRUCTIONS FOR THE USER

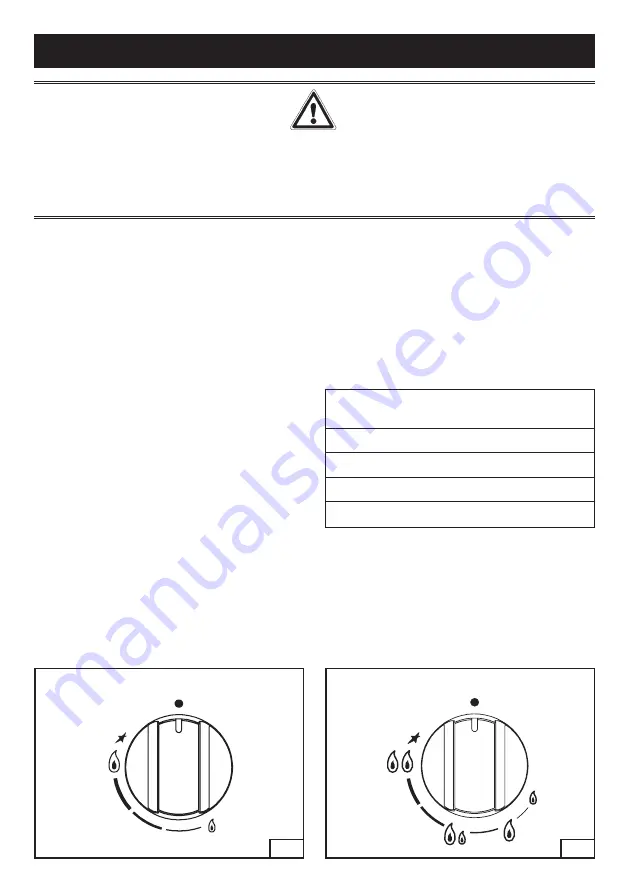

The symbols silk-screen printed on the side of the

knob indicate the correspondence between the

knob and the burner.

Automatic start-up with valves

Turn the corresponding knob anticlockwise up to

the maximum position (large flame, fig.1 - 1/A) and

press the knob.

Once the burner has been started up, keep the

knob pressed for about 5 seconds.

Using the burners

In order to obtain the maximum yield without waste

of gas, it is important that the diameter of the pot is

suitable for the burner potential (see the following

table), so as to avoid that the flame goes out of the

pot bottom (fig.2).

Use the maximum capacity to quickly make the

liquids reach the boiling temperature, and the

reduced capacity to heat food or maintain boiling.

All of the operating positions must be chosen

between the maximum and the minimum ones,

never between the minimum position and the

closing point.

The gas supply can be interrupted by turning the

knob clockwise up to the closing position.

If there is no power supply, it is possible to light the

burners with matches, setting the knob to the start-

up point (large flame).

Burners

Power W

Ø of pots

Auxiliary

1000

10-14 cm

Semi-rapid

1750

16-18 cm

Rapid

3000

20-22 cm

Ultra-rapid

4000

22-24 cm

1

Closed

Maximum

Minimum

1/A

Closed

Maximum

Minimum