8

INSTRUCTIONS FOR THE INSTALLER

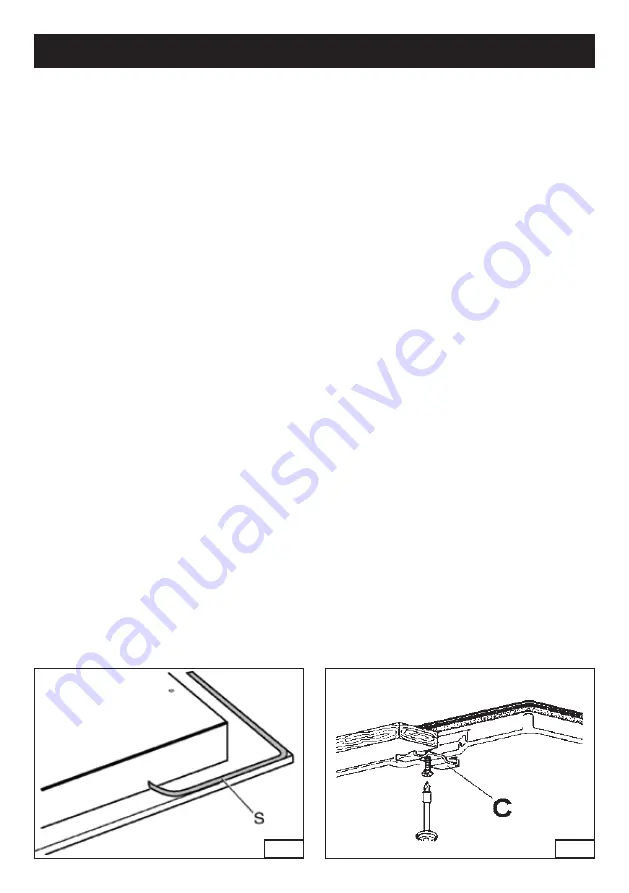

Fastening the top

Every cook-top is equipped with a special washer

having an adhesive side.

- Remove the racks and burners from the top.

- Turn the appliance upside down and lay the

adhesive washer S along the external border of

the glass (fig.5).

- Introduce and place the cook-top in the hole made

e

h

t

h

ti

w

t

i

k

c

o

l

b

n

e

h

t

,

e

r

u

ti

n

r

u

f

f

o

e

c

e

i

p

e

h

t

n

i

screws of the fastening hooks C (fig.6).

Installation room

This appliance is not provided with a device for

exhausting the products of combustion.

Regarding room ventilation rules where appliance

is installed make reference to the legislation, in

conformity with the local regulations.

Gas connection

Make sure that the appliance is adjusted for

the gas type available (see the label under the

appliance). Follow the instructions indicated in the

chapter “gas transformations and adjustments”

for the possible adaptation to different gases. The

appliance must be connected to the gas system

by means of stiff metal pipes or flexible steel pipes

having continuous walls, in compliance with the

regulations in force.

Gas enters the appliance through a cylindrical

threaded male gas union (1/2”).

The connection must not stress the gas ramp.

Once the installation is over, check the connection

seal with a soapy solution.

Electric connection

The appliances does not require to be connected

to the mains power supply as it is provided with a

low voltage ignition generator supplied by a 1,5V

battery.

5

6