9

GAS TRANSFORMATIONS AND ADJUSTMENTS

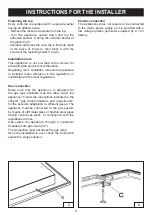

Replacing the nozzles

If the equipment is adjusted for a type of gas that

is different from the one available, it is necessary

to replace the burner nozzles.

The choice of the nozzles to replace must be

made according to the table of the “technical

characteristics”.

Act as follows:

- Remove the racks and burners.

- By means of a straight spanner L, unscrew the

nozzle U (fig.7-7/A) and substitute it with the

corresponding one.

- Tighten the nozzle strongly

For the burner 2 way:

- By means of a straight spanner L, unscrew the

nozzle U1/U2 (fig.7/B) and substitute it with the

corresponding one;

- Tighten the nozzle strongly.

Adjusting the burners

The lowest flame point must always be properly

adjusted and the flame must remain on even if

there is an abrupt shift from the maximum to the

minimum position.

If this is not so, it is necessary to adjust the lowest

flame point as follows:

- start the burner up

- turn the tap up to the minimum position (small

flame)

- remove the knob from the tap rod

- introduce a flat-tip screwdriver in the hole F of

the tap (fig.8-8/A) and turn the by-pass screw up

to a proper adjustment of the lowest flame point.

As regards G30 gas burners, the by-pass screw

must be tightened completely.

7

8

F

7/A

7/B