Short Seam Automat 2211-5 Working Instructions

- B 28 -

Beisler Automated Sewing Equipment

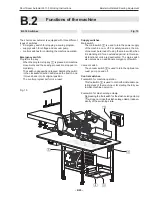

Fig. 21

Fig. 21

NOTE - Vacuum supply!

If the machine is equipped with the optional vacuum pump,

the vacuum supply is now ready for operation.

If the machine is prepared for the on-site vacuum supp-

ly system, the on-site vacuum hose

5

must be connected

to the sleeve

7

of the vacuum valve

6

.

The machine is ready for operation.

B.3

Operation

B.3.2 Preparing the machine

Prior to the production start, check the supply connections,

connect the machine to the compressed air and power

supply systems and prepare the sewing head.

1. Insert needle, pass top thread through needle and insert

bobbin for bottom thread into sewing head (see wor-

king instructions of sewing head manufacturer or sup-

plier).

2.

Fig 21:

Connect machine to compressed air supply by

inserting the plug-in connector

4

of the compressed

air supply hose into the compressed air receptacle in

the operating room. The pressure of the compressed

air is reduced to the required operating pressure of 6

bar by a pressure reducer

3

. Check manometer

2

to see if the correct operating pressure is set. The

pressure reducer is installed at the side mounting wall

of the worktable.

3. Connect machine to power supply system.

WARNING - Electric shock:

Contact with current-carrying components may cause

a lethal electric shock. Check plug and cable before

connecting machine to power supply system.

•

Do not use damaged plugs, sockets or cables to

connect the machine to the power supply system!

•

The machine is connected to a power source of 230

V ±10 % at 50/60 Hz.

•

Before connecting the machine to the power supply

system, check to see if the ratings of the power

supply system in the operating room correspond

with the ratings on the nameplate at the rear of the

machine.

•

If the ratings for voltage (V) and maximum current

(A) do not match, the machine must not be con-

nected.

•

Insert the grounding plug into a properly grounded

and fused power socket.

•

Make sure that the power supply cable is not sub-

ject to tensile or pressure forces.

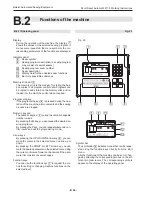

4. Turn machine on by moving the main switch

1

into

the position

I

.

5. Turn the vacuum pump of the machine on. Press vacu-

um switch

8

or open on-site vacuum supply.