10

C

D

A

B

1

4

0

o

6 7 8

1

9

3

2

5

2

90

o

6

10

1

4

3

7

15

4

5

13

12

14

11

10

6

8

7

2

1

9

3

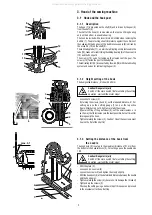

3.5 Feeding mechanism of the needle feed

and of the lower feed wheel

3.5.1 Description

The feeding mechanism is formed by the leverage (1) which is driven

from the main shaft through the eccentric with connection rod (2). The

feeding motion is transmitted by the shaft (3) on the clutch of the

bottom feed (7).

The engaging and the disengaging function of the clutch (7) is controlled

from the lower shaft (8) through the eccentric with the connecting rod

(9) and through the wedge coupling (10).

The feeding movement is transmitted by the shaft (11) through the

chain transmission (12) onto the wheel feeder (13).

The stitch length is set by the knob (14) through the leverage (15) to

the feeding mechanism (1).

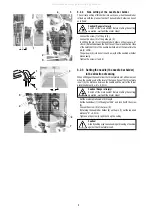

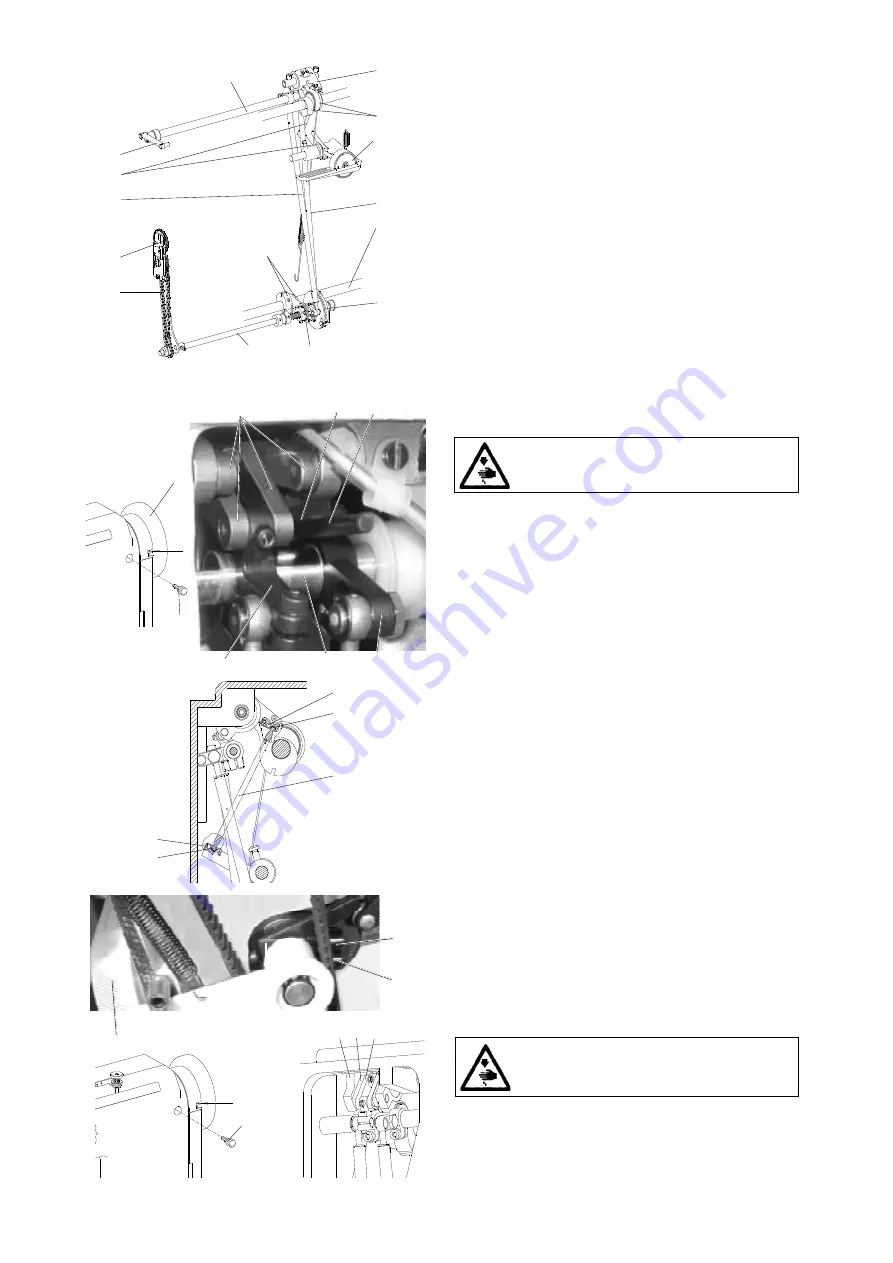

3.5.2 Stitch length mechanism

3.5.2.1 Setting the upper eccentric

The eccentric (1) must be set in its angular position in such a way that

the horizontal component of the needle motion is in a phase delay from

the vertical component of this movement. This refers to the angle of

90

°

on the handwheel (2), when the setting stick (3) is engaged into

the eccentric (1) and leans from above against the feeding shaft (4).

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

-

Set the angle 90

°

on the handwheel (2) and fix it with the screw (5)

which is component part of the accessory of the machine (tighten it

with care).

- Loosen the gripping joints of the levers (6) and (7).

- Turn the feeding shaft (4) in such a way, so that the recesses (flats)

point towards the bedplate (owing to the unambi-guous setting of

the eccentric by means of the setting bar).

- Insert the setting bar (3) into the hole in the eccentric (1) and prop

it from above against the feeding shaft (4).

- Shift axially the eccentric (1) on the shaft into its extreme positions

and place it in the middle.

- Tighten the screws of the eccentric (1) to the maximum (one screw

first and, after having turned slightly the hand-wheel, the second

screw as well).

- Turn the feeding shaft (4) back into the position for setting the

leverage in such a way, so that the levers (10) of the mechanism pass

in the spots of the recesses.

- Tighten the gripping joints of the levers (6) and (7).

- Test the sufficient clearance in the recesses of the feeding shaft (4)

and, using the levers (10) with the maximum stitch length forward

and rearward push against the reverse stitching lever.

- Correct eventually the position of the feeding shaft.

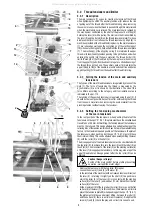

3.5.2.2

Setting the prop

In this machine with a wheel feed, the prop (1) is mounted in the pits

(A and C) as per the drawing.

3.5.2.3a

Forward and rearward stitch length

distribution (rough)

The cam (1) is to be set at the respective angle in such a way that the

stirrup (6) is oriented in such a position, so that the connecting rods (7

and 8) are in a line with a thoroughly screwed in knob (9) and with

turning the handwheel at 0

°

. This setting can be done only after having

set the top eccentric according to the paragraph 3.5.2.1.

Caution! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Set the zero stitch /screw in the knob (9) to the bottom of the cam

(1)/.

- Set the angle 0

°

on the handwheel and lock it with the screw (4).

- Turn the screw (3) in the respective sense in such a way that the

connecting rods (7 and 8) are in a line and tighten the screw (2).

All manuals and user guides at all-guides.com