4

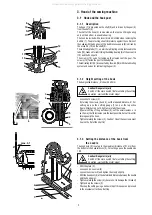

3.1.7 Setting the regulation of the hook lubrication

By turning the lubricating tube (1) in the sense of the arrow (2), the

size of the contacting surface between the wick (3) and the felt insert

(4) is regulated. In this way, the speed of the capillary lift of oil into the

felt insert (5) is influenced, from which oil is wiped on the surface (6)

and is driven by centrifugal force into the hook path (7).

Setting of full lubrication

- Turn the screw (8) into the position (9).

Setting of limited lubrication

- Turn the screw (8) into the position (10).

After having ended the regulation, set the height of the lubricating tube

(1) at 0.4 mm from the eccentric (11).

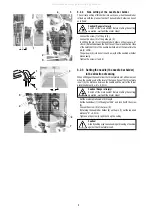

3.1.8 Replacement of the hook

Caution! Danger of injury!

Switch off the main switch ! Before starting the setting

operation, weit until the motor stops!

- Remove the throat plate and the trimming knife.

- Unscrew the screws (1) and remove the gib (2).

- After having suitably turned a bit the hook, remove the bobbin case

(3).

- Unscrew thorougly the screw (4).

- Remove the body of the hook (5) upwards.

- When mounting, the procedure is inverse.

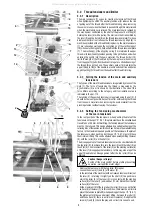

3.1.9 Setting the gear

The mutual angular orientation of the gear wheel (1) relative to the gear

wheel (2) should ensure the accessibility of the screw (5) at the moment

when the hook point comes to lie opposite the needle (4). The wheel

(2) is to be set with its gear rim symmetrically to the centre of the gear

wheel (1). The clearance between the gear wheels is to be the least

possible.

Caution ! Danger of injury!

Switch off the main switch! Before starting the setting

operation, wait until the motor stops!

- Set the angle of 2O8

°

on the handwheel (6) and lock it with the

screw (7).

- On the removed post of the hook (8), according to the paragraph

3.1.10, the hook point (3) is to be turned a bit according to the

illustration.

- Turn the gear wheel (2) into the suitable position and insert the post

of the hook into the machine according to the respective arrows.

Check up, whether the screw (5) is accessible and, if not, repeat the

procedure.

- Set the the distance of the hook from the needle according to the

paragraph 3.1.3.

- Set the precise angular displacement of the hook according to the

paragraph 3.1.4.

- Loosen the screw (10) and tighten them slightly.

- Set the clearence in the gear in turning the screws (9). Check up,

whether the gear has a clearance during the whole revolution of the

hook. Turn the handwheel step by step by 15

°

and, with each step,

grasp the hook and try, if there is an angular dead travel. Tighten

carefully the screws (9).

- Tighten duly the screws (10) and try anew the clearance of the gear.

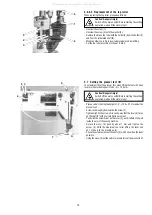

1

2

3

4

5

1

2

1

3

4

5

6

7

11

0,4

8

10

9

15

o

1

5

2

4

3

7

6

208

o

9

8

10

10

~0,5

All manuals and user guides at all-guides.com