Page 4

Section 6 – Probes and Probe Stacks

Dukane Manual Part No. 403-583-00

Ultrasonic Horn

The horn transfers the ultrasonic mechanical vibrations

(originating at the transducer in the probe housing) to the

plastic parts through direct physical contact. The horn

is precision machined and designed to vibrate at either

20kHz, 30kHz, 40kHz, 50kHz or 70kHz. The tuning is

accomplished using electronic frequency measurement.

Inherent variations in material composition prevent tuning

by dimensional machining alone.

There are many different horn profile styles depending

upon the process requirements. Factors which affect

the horn design are the materials to be welded and the

method of assembly. Horns are usually constructed from

aluminum, hardened steel or titanium. As the frequency

increases, vibration amplitude typically decreases, but

internal stress in the horn increases. Higher frequencies

are used for delicate parts that cannot handle a lot of

amplitude. Some factors to keep in mind for high–

frequency (e.g. 40kHz) ultrasonic welding versus low–

frequency (e.g. 20kHz) ultrasonic welding are listed here.

1. Stress in the horn is higher at high frequencies.

2. Wear on the horn is greater at high frequencies.

3. Clean and flat mating surfaces between the horn, booster

and transducer are more critical at high frequencies.

Booster

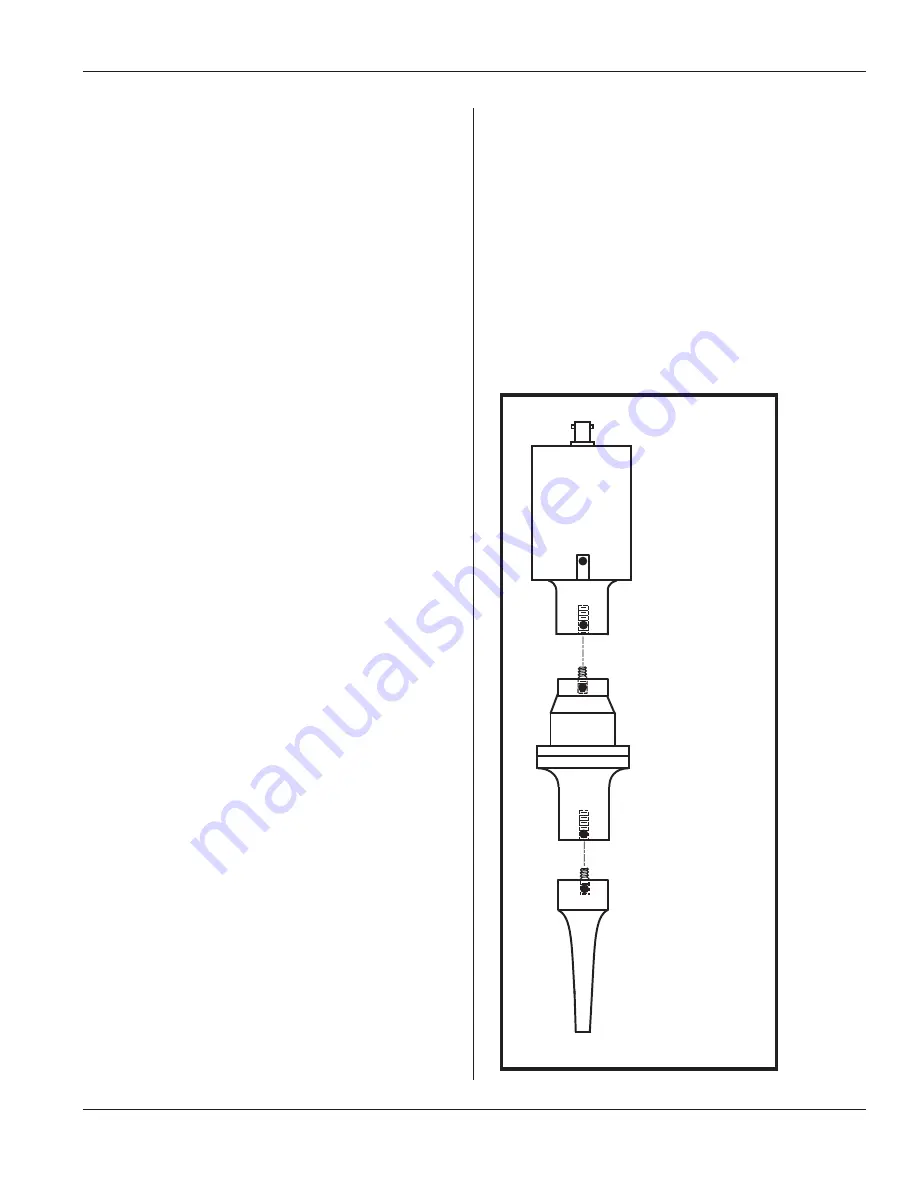

The function of a booster is to alter the gain (i.e. output

amplitude) of the probe. A booster is amplifying if its gain

is greater than one and reducing if its gain is less than one. A

neutral or coupling booster is used to provide an additional

clamping location for added probe stack stability. A probe

designed to be mounted in a fixture along with a booster and

horn is shown in Figure 6–2. This is commonly referred to

as a stack. As indicated, the components are secured with

threaded studs.

Probe

Housing

Booster

Horn

Figure 6–2

Probe, Booster and Horn