www.factorybuysdirect.com

200423-01A

25

OPERATION

Note: If pilot does not stay lit, refer to

Troubleshooting,

pages 29 through 32. Also

contact a qualified service technician or gas

supplier for repairs. To light pilot with match,

see Manual Lighting Procedure.

7.

Keep control knob pressed in for 30

seconds after lighting pilot. After 30 sec

-

onds, release control knob. If control knob

does not pop up when released, contact a

qualified service person or gas supplier for

repairs.

Note" If pilot goes out, repeat steps 3

through 7. This fireplace has a safety in

-

terlock system. Wait one (1)minute before

lighting pilot again.

8.

To light the burner, partially press down

the control knob slightly and rotate coun

-

terclockwise

. Release the downward

pressure on the knob while continuing to

turn until the knob locks in the ON position.

The main burner should ignite. Do not

operate between locked positions.

9.

Make sure fireplace screen is in place

before operating fireplace.

10.

If fireplace will not operate, follow the

instructions To Turn Off Gas To Appliance,

and call your service technical or gas

supplier.

Shutting Off Fireplace

1.

Push in control knob slightly and turn

clockwise

to the OFF position. Do

not force.

2.

Close equipment shutoff valve.

Shutting Off Burner Only (pilot stays lit)

Push in and turn knob clockwise

to

the PILOT position.

1.

Open Screen.

2.

Follow steps 1 through 7 under Lighting

Instructions, page 24.

3.

With control knob in the PILOT position,

strike a match, and hold near pilot. Press

in control knob; pilot should light.

4.

Keep control knob pressed in for 30 sec

-

onds after lighting pilot. After 30 seconds,

release control knob.

5.

Make sure the fireplace screen is in place

before operating fireplace.

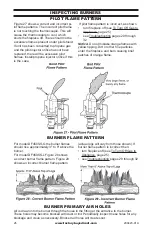

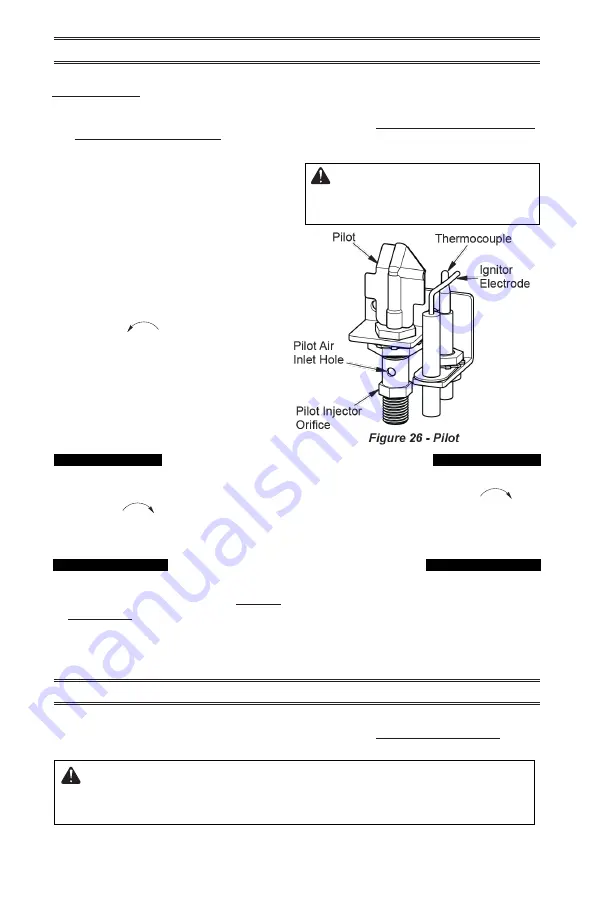

INSPECTING BURNERS

IMPORTANT: Owner's should check pilot flame pattern and burner flame pattern often.

Incorrect flame patterns indicate the need for cleaning (see

Care and Maintenance, page

27) or service.

CAUTION: Do not try to adjust

heating levels by using the

equipment shutoff valve.

WARNING: Only a qualified service person should service and

repair fireplace. This includes maintenance requiring replacement

or alteration of components.

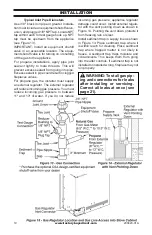

TO TURN OFF GAS TO APPLIANCE

MANUAL LIGHTING PROCEDURE