www.factorybuysdirect.com

27

200257-01A

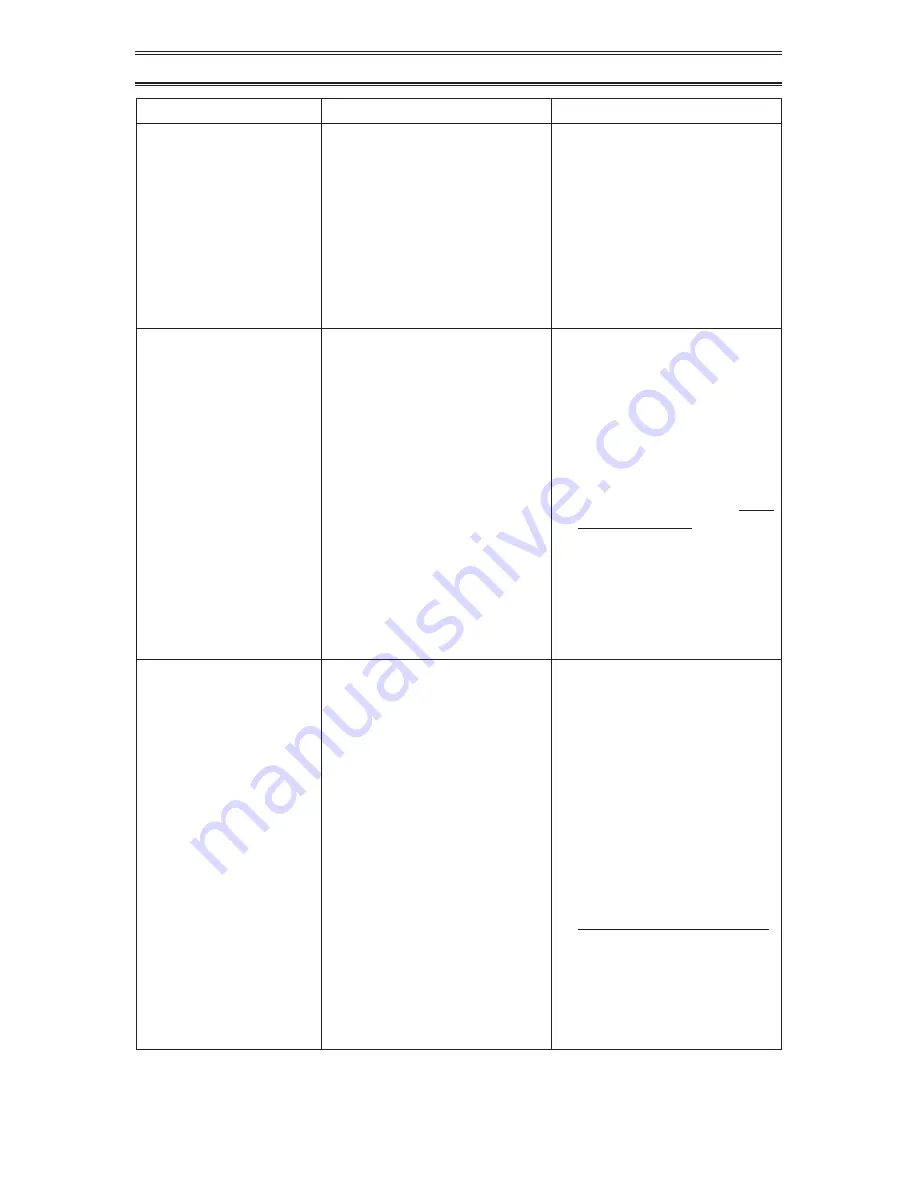

Problem

Possible Cause

Corrective Action

When ignitor button is

pressed in, there is no

spark at ODS/pilot

1. Ignitor electrode is posi-

tioned wrong. Ignitor elec-

trode is broken.

2. Ignitor electrode is not con-

nected to ignitor cable.

3. Ignitor cable is pinched or

wet.

4 Broken ignitor cable.

5. Bad piezo ignitor.

6. Low battery.

1. Replace electrode.

2. Replace ignitor cable

3. Free ignitor cable if pinched

by any metal or tubing. Keep

ignitor cable dry.

4. Replace ignitor cable.

5. Replace piezo ignitor.

6. Replace battery.

When ignitor button is

pressed in there is a

spark at ODS/pilot but

no ignition.

1. Gas supply is turned off or

equipment shutoff valve is

closed.

2. Control knob not fully

pressed in while pressing

ignitor button.

3. Air in gas lines (new instal-

lation or recent gas interrup-

tion).

4. ODS / pilot is clogged.

5. Incorrect inlet gas pressure

or inlet regulator is damaged.

6. Control knob not in PILOT

position.

7. Depleted gas supply (pro-

pane).

1. Turn on gas supply or open

equipment shutoff valve.

2. Fully press in control knob

while pressing ignitor button.

3. Continue holding down con-

trol knob. Repeat igniting op-

eration until air is removed.

4.

Clean ODS/pilot (see

Care

and Maintenance

, page 23) or

replace ODS/pilot assembly.

5. Check inlet gas pressure or

replace inlet gas regulator.

6. Turn control knob to PILOT

position.

7. Contact local propane/LP

gas company.

ODS/pilot lights but flame

goes out when control

knob is released.

1. Control knob is not fully

pressed in.

2. Control knob is not pressed

in long enough.

3. Equipment shutoff valve is

not fully open.

4. Thermocouple connection is

loose at control valve.

5. Pilot flame not touching

thermocouple, which allows

thermocouple to cool, caus-

ing pilot flame to go out. This

problem could be caused by

one or both of the following:

A) Low gas pressure

B) Dirty or partially clogged

ODS/pilot

6. Thermocouple damaged.

7. Control valve damaged.

1. Press in control knob fully.

2. After ODS/pilot lights, keep

control knob pressed in 30

seconds.

3. Fully open equipment shutoff

valve.

4. Hand tighten until snug, and

then tighten 1/4 turn more.

5. A) Contact local natural or

propane/LP gas company

B) Clean ODS/pilot (see

Care and Maintenance

,

page 23) or replace ODS/

pilot assembly

6. Replace thermocouple.

7. Replace control valve.

TROUBLESHOOTING