13

Storage

Before long-term storage, water blast the machine and remove mud and

excess soil.

Maintenance & Care

(Continued)

Your new Maxi-Till Cultivator will give long and efficient service if given

normal care and maintained properly.

Maintenance Schedule

1

Bolted Connections

All bolted connections on the machine should be checked after the

first use (or 50Ha) and retightened if necessary. Thereafter, check

the connections at regular intervals to minimise equipment damage

and accidents resulting from loosening of the fasteners. It is

suggested that this check is done annually or after every 500Ha

(whichever occurs first).

2

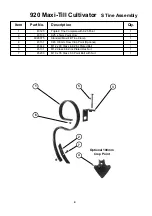

S Tines and Tine Points

Prior to daily operation, check that all tine clamps and points are

tight.

3

Framework

The framework structure should be inspected annually for defects,

i.e. cracks in members or welded connections. The framework

should be cleaned prior to inspection.

4

Lubrication

Crumbler bearings are prepacked and sealed. However, the

housings requre greasing weekly or every 250Ha (whichever occurs

first). Castrol MP grease is recommended.

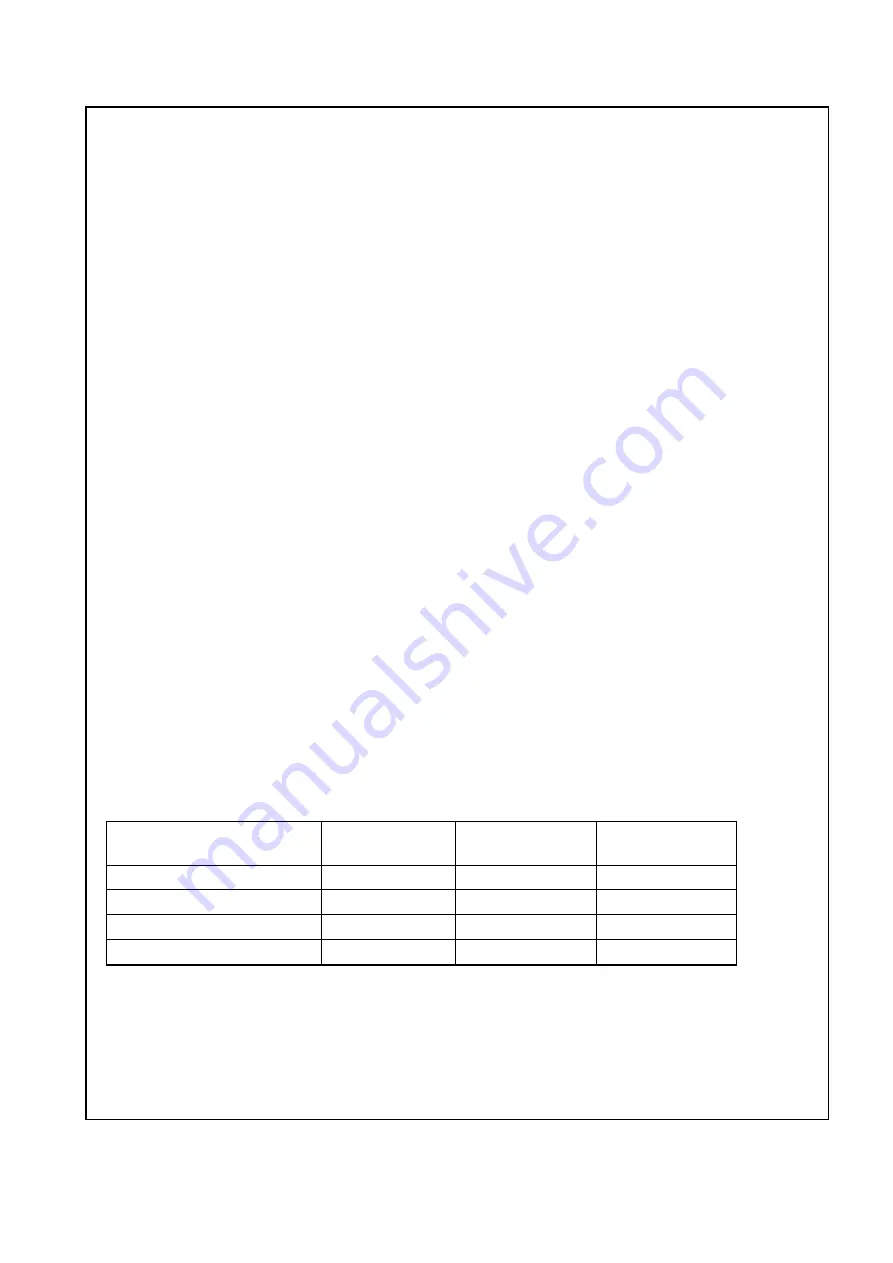

Components

Daily

Weekly

Annually

(or after 50Ha) (or after 250Ha)

(preseason)

S Tines & Points

•

•

•

•

•

•

Crumbler Pivot Pin Fasteners

•

•

•

•

Bolted Connections

•

•

•

•

Framework

•

•

Schedule Summary

Pt. No. 67202

Issue 0806