SAFETY - General

This section of the manual offers general guidelines

for the safe operation of machinery.

It does not replace

local safety regulations. These guidelines were current at

the time of publication, but may be superseded by later

regulations.

Clough Agriculture has made every effort to highlight all

risks to personnel or property. Owners and operators have

a responsibility to exercise care and safe work practices at

all times in the vicinity of the machine.

Owners are advised to keep up to date on safety issues

and to communicate these to all users of the machine.

Contact the Occupational Safety and Health Service

(OSH) for further information about general safety aspects.

If you have safety concerns specifically related to this

machine, contact your dealer immediately.

Operator Safety

Read this manual carefully before operating new

equipment. Learn how to use this machine safely.

Be thoroughly familiar with the controls and the proper use

of the equipment before using it.

Take careful note of all safety instructions both in this

manual and on the machine itself. Failure to comply with

instructions could result in personal injury and/or damage

to the machine.

Replace missing or damaged safety signs on the machine

and ensure that these remain clearly visible.

It is the owner’s responsibility to ensure that anyone

who operates, adjusts, lubricates, maintains, cleans or

uses the machine in any way has had suitable

instruction and is familiar with the information in this

manual (particularly with regard to safety aspects).

Operators and other users of the machine should be

aware of potential hazards and operating limitations.

Be Prepared for Emergencies

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance,

hospital and fire department near your telephone.

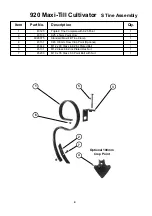

N.B. Throughout this

manual important safety

information is indicated

by these symbols in the

margin:

A prohibition

should

be observed under all

circumstances.

A warning

indicates a

hazard that could

cause death or injury if

the warning is ignored.

A caution

indicates a

hazard that may cause

damage to property if

the caution is ignored.

5

Pt. No. 67202

Issue 0806