22

6.1 General

• Installations shall comply with Authority having jurisdiction

and in absence of such with:

»

U.S. ANSI Z223.1 /NFPA 54 in the United States

»

CSA B149.1 in Canada.

• This boiler requires a dedicated direct vent system.

• Vent connections serving appliances vented by natural draft

shall not be connected into any portion of mechanical draft

systems operating under positive pressure.

• Materials used in the U.S. shall comply with Authority

having jurisdiction and in absence of such with: ANSI/

ASTM D1785, ANSI/ASTM F441, ANSI/ASTF493, UL1738 or

ULS636.

• Canadian installations only: All venting material, primer

and glue must be listed to ULC S636.

• Venting system must be free to expand and contract.

• Vent system must have unrestricted movement through

walls, ceilings and roof penetrations.

• Check for proper joint construction when joining pipe to

fittings.

•

If vent is penetrating ceilings and floors, openings must

have means of fire stopping in joist areas and proper

firestop spacer assemblies installed.

•

Standard roof flashing methods must be used to install roof

flashing.

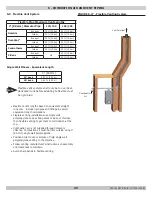

• Frame wall and roof openings to provide support for

attachment of termination assemblies.

• Support piping in accordance with pipe manufacturer's

instruction and authority having jurisdiction. In absence

of manufacturer's instruction use pipe hooks, pipe straps,

brackets, or hangers of adequate and strength located

at intervals of 4 ft (1.2m) or less. Allow for expansion/

contraction of pipe.

• Support horizontal sections of vent pipe to prevent sags

capable of accumulating condensate.

6 - COMBUSTION AIR AND VENT PIPING

WARNING

Fire, explosion, and asphyxiation hazard. Improper

installation could result in death or serious

injury. Read these instructions and understand all

requirements before beginning installation.

!

• Assemble vent materials in accordance with venting

manufacturer’s instructions.

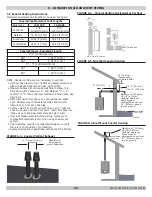

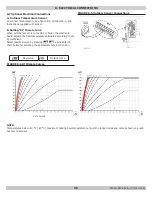

• Slope exhaust pipe minimum of 1/4” per foot, or vent

manufacturer’s recommendation, whichever is greater;

back toward the boiler.

•

Any "in line" elbows in flue system must be taken into

consideration. First elbow on the top of the boiler is

included in equivalent length calculations.

WARNING

ABS/PVC venting shall not to be used this product.

Use of DWV plumbing pipes to vent this boiler shall be

prohibited.

Use of cellular core PVC (ASTM F891), cellular core

CPVC, or Radel® (polyphenolsulfone) in venting

systems shall be prohibited.

Covering non-metallic vent pipe and fittings with

thermal insulation shall be prohibited.

Failure to follow these instructions could result in death

or serious injury.

!

Note

Follow venting manufacturer's equivalent lengths

for specialty fittings.

6.2 Removal of Existing Boiler From Common Vent

System

When existing boiler is removed from common venting

system, common venting system is likely to be too large for

proper venting of appliances remaining connected to it.

After removal of existing boiler, following steps shall be

followed with each appliance remaining connected to common

venting system placed in operation, while other appliances

remaining connected to common venting system are not in

operation:

• Seal any unused openings in common venting system.

• Visually inspect venting system for proper size and

horizontal pitch. Determine there is no blockage or

restrictions, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

• When practical, close all building doors, windows, and

all doors between space in which appliances remaining

connected to common venting system are located and

other spaces of building. Turn on clothes dryer and any

appliance not connected to common venting system.

Turn on exhaust fans, such as range hoods and bathroom

exhaust so they will operate at maximum speed. Do not

operate summer exhaust fan. Close fireplace dampers.

• Turn on appliance being inspected. Follow lighting

instructions. Adjust thermostat so appliances will operate

continuously.

• Test for spillage at draft hood relief opening after 5

minutes of main burner operation. Use flame of match or

candle, smoke from cigarette, cigar or pipe.

• Determine each appliance remaining connected to common

venting system properly vents when tested as outlined

above. Then return doors, windows, exhaust fans and any

other gas-burning appliance to their previous condition of

use.

• Any improper operation of common venting system

should be corrected so installation conforms with National

Fuel Code, ANSI Z223.1/NFPA 54 and/or Natural Gas

and Propane Installation Code, CAN/CSA B149.1. When

re-sizing any portion of common venting system, common

venting system should be re-sized to approach minimum

size as determined using appropriate tables in Chapter 13

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/

or Natural Gas and Propane Installation Code, CAN/CSA

B149.1.

240011947 REV B, [03/31/2018]

Summary of Contents for DCB-125

Page 2: ...DCC 205 ...

Page 4: ...DCB 165 ...

Page 65: ...61 APPENDIX A WIRING DIAGRAMS A 1 MODELS 125 Heat Only 240011947 REV B 03 31 2018 ...

Page 66: ...62 APPENDIX A WIRING DIAGRAMS A 2 MODELS 165 Heat Only 240011947 REV B 03 31 2018 ...

Page 67: ...63 APPENDIX A WIRING DIAGRAMS A 3 MODELS 150 Combi 240011947 REV B 03 31 2018 ...

Page 68: ...64 APPENDIX A WIRING DIAGRAMS A 4 MODELS 205 Combi 240011947 REV B 03 31 2018 ...

Page 69: ...65 NOTES 240011947 REV B 03 31 2018 ...

Page 70: ...66 NOTES 240011947 REV B 03 31 2018 ...

Page 81: ...9 125 WITH ZONE CIRCULATOR PUMPS 125 with Zone Circulator Pumps PN 240011430 REV G 03 31 18 ...

Page 84: ...12 125 WITH ZONE VALVES PIPING DIAGRAM 125 with Zone Valves PN 240011430 REV G 03 31 18 ...

Page 90: ...18 165 with Zone Valves 165 WITH ZONE VALVES PIPING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 94: ...22 150 205 WITH ZONE PUMPS WIRING DIAGRAM 150 205 With Zone Pumps PN 240011430 REV G 03 31 18 ...

Page 102: ...30 MODEL 125 Heat Only 125 HEAT ONLY WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 103: ...31 MODEL 165 Heat Only 165 HEAT ONLY WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 104: ...32 MODEL 150 Combi 150 COMBI WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 105: ...33 MODEL 205 Combi 205 COMBI WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 110: ...38 Low Water Cutoff Detail LOW WATER CUTOFF NO NO YES PN 240011430 REV G 03 31 18 ...

Page 111: ...39 NOTES PN 240011430 REV G 03 31 18 ...

Page 112: ......

Page 115: ......

Page 116: ......