25

6 - COMBUSTION AIR AND VENT PIPING

WT

(X)

(X)

Wall Thickness

WT = Wall Thickness

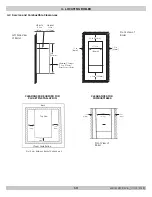

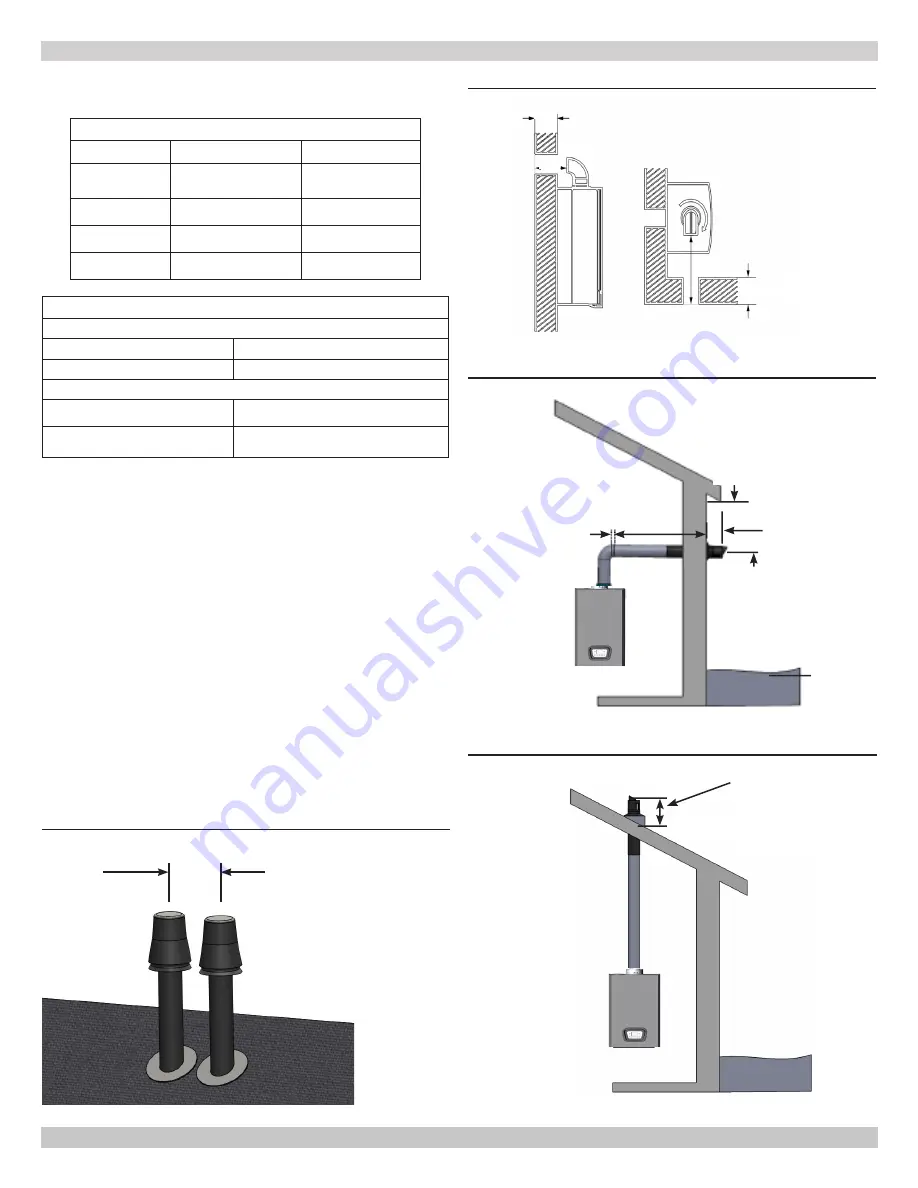

FIGURE 6-5 Side Wall Coaxial Venting

FIGURE 6-6 Roof Mount Coaxial Venting

FIGURE 6-4 - Coaxial Venting Horizontal or Vertical

2” (50 mm)

X

Min. 8" (181 mm)

Max. 14" (356 mm)

Maintain 12"(305mm)

US (18"(457mm)

Canada) clearance

above highest

anticipated snow level

24" (610mm) above

roof or ground

Ground

Anticipated

Snow Line

Maintain 12"(305mm)

US (18"(457mm)

Canada) clearance

above highest

anticipated snow level

24" (610mm) above

roof or ground

Anticipated

Snow Line

18" Vertical

Clearance to

ventilated soffit

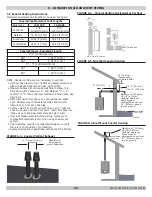

6.7 Coaxial Venting Instructions

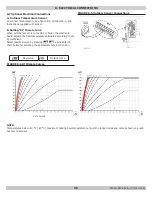

Maximum equivalent flue lengths for Coaxial venting are:

Coaxial Pipe Maximum Vent Lengths

Boiler Size

125/150

165/205

Vent Size

4"/2"

[100mm/60mm]

5"/3"

[128mm/80mm]

Natalini

32.80 ft [10m]

32.80 ft [10m]

DuraVent

®

27.88 ft [8.5m]

32.80 ft [10m]

Centrotherm

24.60 ft [7.5m]

32.80 ft [10m]

Coaxial Elbows - Equivalent length

4"/2" [100mm/60mm]

45°

1.64 ft. [0.5m]

90°

3.28 ft. [1.0m]

5” / 3” [128mm/80mm]

45°

1.64 ft. [0.5m]

90°

3.28 ft. [1.0m]

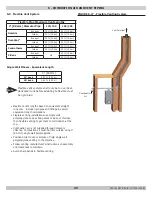

NOTE: Coaxial venting can run horizontal or vertical.

•

Connect flue elbow to top of boiler and adjust direction of

elbow to desired orientation (rear, right or left).

• Measure distance from outside wall face to elbow, this

dimension will be known as 'X", add distance "Y" + 2"

(50mm) to "X" this is the total dimension of the vents. See

Figure 6.4.

• Mark dimension from above on outer aluminum intake

vent. Measure length of waste material, and transfer

dimension to inner grey flue pipe.

•

Remove waste from both vents (flue and air). Verify cut

ends are square and free from burrs. Insert flue back into

intake air vent and pass them through hole in wall.

• Check all measurements before cutting. Clearance to

combustible materials is zero when using coaxial vent

system.

• After installing venting use calibrated analyzer to verify

there is no recirculation of combustion.

• Ensure termination is positioned with slots at the bottom.

FIGURE 6-3 - Coaxial Vertical Exhaust

12" (305mm) Minimum

Separation

Manufacturer

Recommends

Greater Separation

240011947 REV B, [03/31/2018]

Summary of Contents for DCB-125

Page 2: ...DCC 205 ...

Page 4: ...DCB 165 ...

Page 65: ...61 APPENDIX A WIRING DIAGRAMS A 1 MODELS 125 Heat Only 240011947 REV B 03 31 2018 ...

Page 66: ...62 APPENDIX A WIRING DIAGRAMS A 2 MODELS 165 Heat Only 240011947 REV B 03 31 2018 ...

Page 67: ...63 APPENDIX A WIRING DIAGRAMS A 3 MODELS 150 Combi 240011947 REV B 03 31 2018 ...

Page 68: ...64 APPENDIX A WIRING DIAGRAMS A 4 MODELS 205 Combi 240011947 REV B 03 31 2018 ...

Page 69: ...65 NOTES 240011947 REV B 03 31 2018 ...

Page 70: ...66 NOTES 240011947 REV B 03 31 2018 ...

Page 81: ...9 125 WITH ZONE CIRCULATOR PUMPS 125 with Zone Circulator Pumps PN 240011430 REV G 03 31 18 ...

Page 84: ...12 125 WITH ZONE VALVES PIPING DIAGRAM 125 with Zone Valves PN 240011430 REV G 03 31 18 ...

Page 90: ...18 165 with Zone Valves 165 WITH ZONE VALVES PIPING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 94: ...22 150 205 WITH ZONE PUMPS WIRING DIAGRAM 150 205 With Zone Pumps PN 240011430 REV G 03 31 18 ...

Page 102: ...30 MODEL 125 Heat Only 125 HEAT ONLY WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 103: ...31 MODEL 165 Heat Only 165 HEAT ONLY WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 104: ...32 MODEL 150 Combi 150 COMBI WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 105: ...33 MODEL 205 Combi 205 COMBI WIRING DIAGRAM PN 240011430 REV G 03 31 18 ...

Page 110: ...38 Low Water Cutoff Detail LOW WATER CUTOFF NO NO YES PN 240011430 REV G 03 31 18 ...

Page 111: ...39 NOTES PN 240011430 REV G 03 31 18 ...

Page 112: ......

Page 115: ......

Page 116: ......