5

loCAtING the BoIleR

You must provide for enough fresh air to assure

proper combustion. The fire in the boiler uses

oxygen. It must have a continuous supply. The air

in a house contains only enough oxygen to supply

the burner for a short time. Outside air must enter

the house to replace that used by the burner. Study

following examples 1 and 2 to determine your fresh

air requirements.

EXAMPLE 1: Boiler Located I

n Unconfined Space

An unconfined space is defined as a space whose

volume is not less than 50 cubic feet per 1,000 Btu

per hour of the total input rating of all appliances

installed in that space.

If your boiler is in an open area (un-partitioned

basement) in a conventional house, the air that leaks

through the cracks around doors and windows will

usually be adequate to provide air for combustion.

The doors should not fit

.

tightly. Do not caulk the

cracks around the windows.

Equipment located in buildings of tight construction

shall be provided with air for combustion, ventilation,

and dilution of flue gases using the methods

described in example 2b or shall be specially

engineered. The authority having jurisdiction must

approve specially engineered installations.

NOTE:

If you use a fireplace or a kitchen or bath

-

room exhaust fan, you should install an outside

air intake. These devices will rob the boiler and

water heater of combustion air.

fReSh AIR foR ComBuStIoN

Provision for combustion and ventilation air

must be in accordance with the National fuel Gas

Code, ANSI Z223.1- latest revision, or applicable

provisions of the local building codes.

!

!

WARNING

Be sure to provide enough fresh air for

combustion. Enough air insures proper

combustion and

assures that no hazard will

develop due to the lack of oxygen.

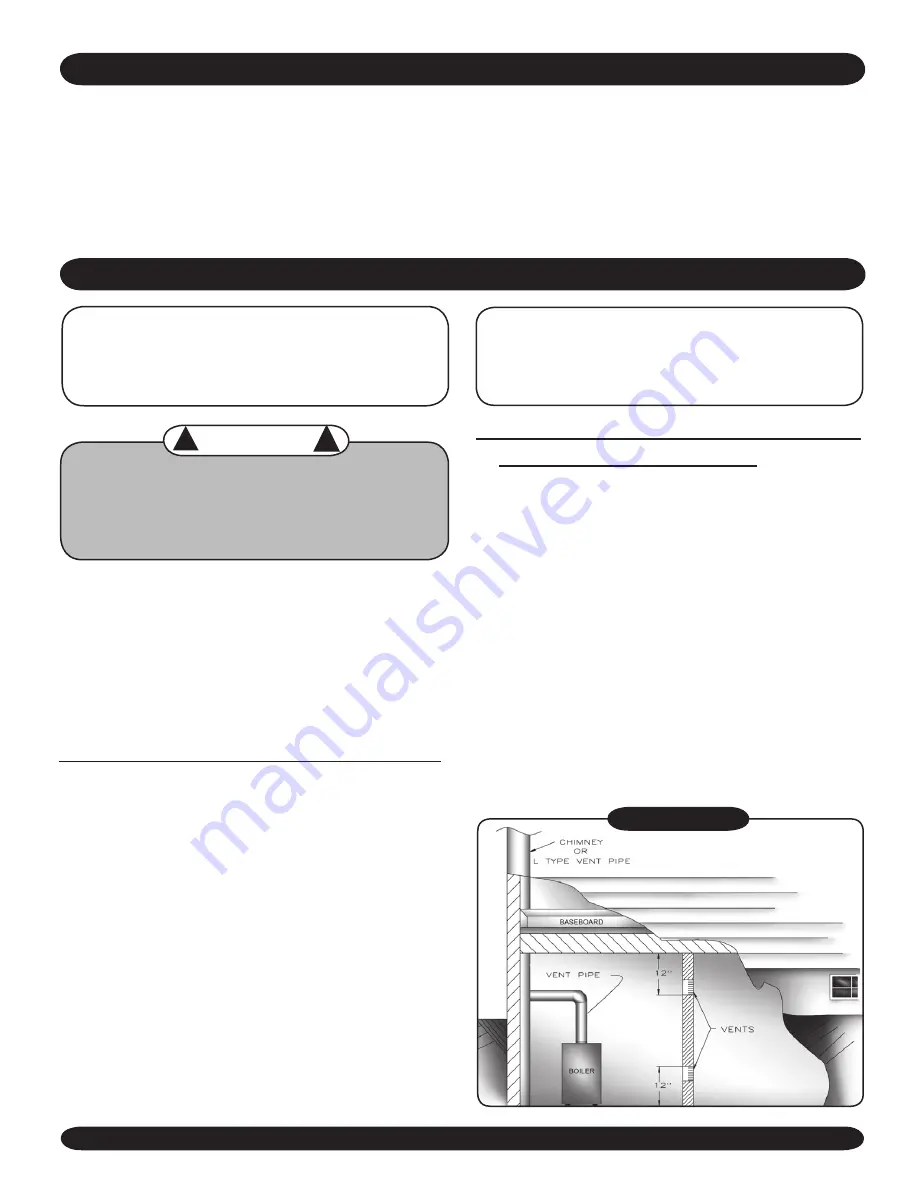

EXAMPLE 2: Boiler Located I

n Confined Space

A. All Air From Inside The Building:

The confined

space shall be provided with two permanent

openings communicating directly with an additional

room(s) of sufficient volume so that the combined

volume of all spaces meets the criteria for an

unconfined space. The total input of all gas utilization

equipment installed in the combined space shall

be considered in making this determination. Each

opening shall have a minimum free area of one

square inch per 1,000 Btu per hour of the total input

rating of all gas utilization equipment in the confined

space, but not less that 100 square inches. One

opening shall be within 12 inches of the top and one

within 12 inches of the bottom of the enclosure. The

minimum dimension of air openings shall not be less

than 3 inches (see

Figure #3A

).

Base part number. We use a 2” Cladlite pad as

a combustible floor base. These are available

from your local supplier. Use 24” x 30” pad for

2-5 section boilers, and a minimum 30” x 30”

pad for 6-7 sections boilers. The boiler must be

centered on the combustible floor base.

8. The boiler shall be installed such that the automatic

gas ignition system components are protected

from water (dripping, spraying, rain, etc.) during

appliance operation and service (circulator

replacement, control replacement, etc..)

Figure #3A

Summary of Contents for XEB-2

Page 36: ...85 Middle Rd Dunkirk NY 14048 ...