9

INStAllAtIoN-SYStem pIpING

!

!

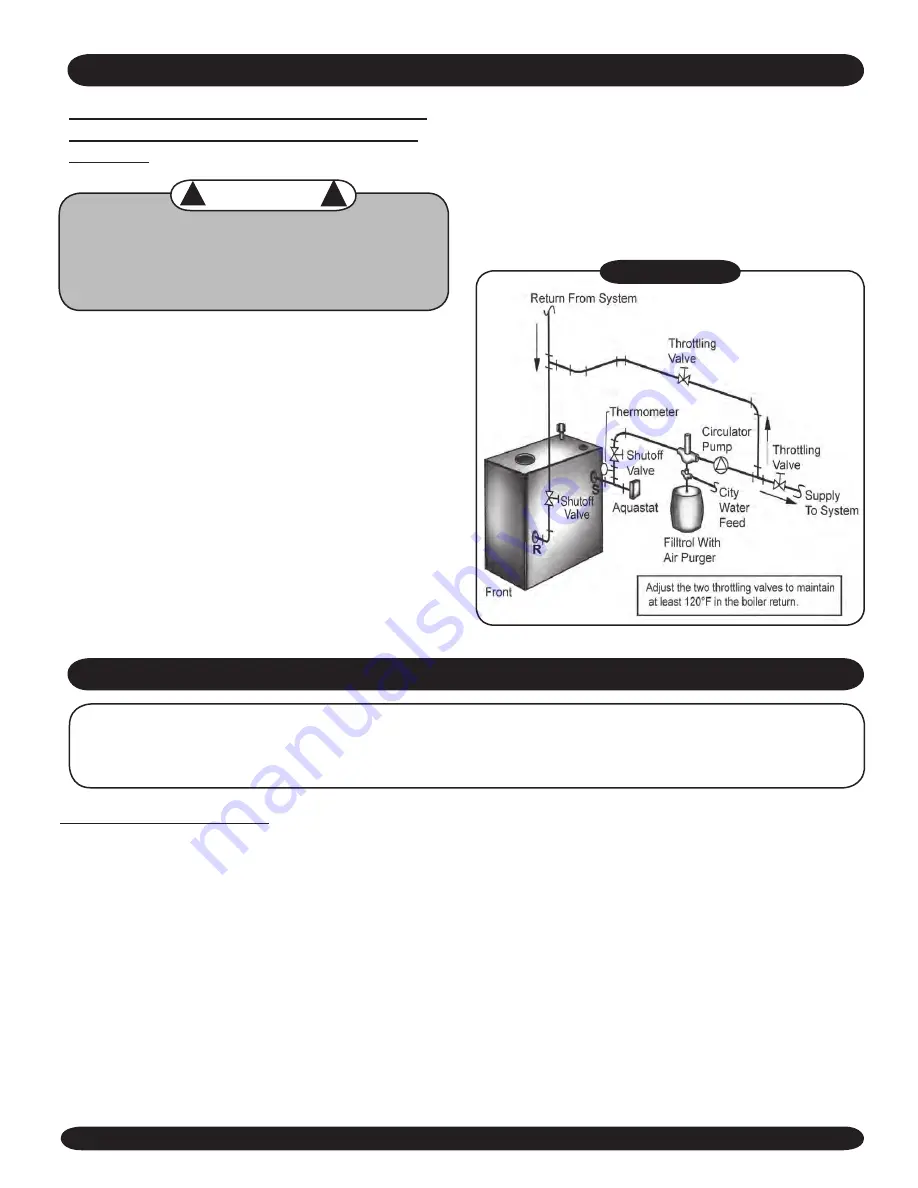

Figure #7

Low Design Water Temperature Systems

(Below 140° F) And Large Water Content

Systems:

WARNING

Significant condensation may form in this

boiler and/or the venting system if the boiler

is operated with return temperatures of less

than 120° F.

This condensation is corrosive and can eventu-

ally cause severe damage to the boiler and vent-

ing system. The minimum design return water

temperature to prevent this condensation in the

boiler and venting is 120°F. The minimum high

limit setting is 140°F.

If the boiler is to be used in a heating system

where design water temperatures below 140°F

are desired (e.g. radiant floor heating), a 3-way

or 4-way mixing valve or suitable alternative (e.g.

bypass piping,

Figure #7

) is required to prevent

low temperature (below return 120°F) return wa

-

ter from entering the boiler. When using a mix-

ing valve, follow the manufacturer’s installation

instructions.

If the boiler is to be connected to a system hav-

ing a large water content (such as a former grav

-

ity system), it is suggested to use bypass piping

shown in

Figure #7

.

ChImNeY ANd VeNt pIpe CoNNeCtIoN

for boilers for connection to gas vents or chimneys, vent installations shall be in

accordance with the National Fuel Gas Code, ANSI Z223.1- latest revision and applicable

provisions of the local building codes.

CHECK YOUR CHIMNEY

This is a very important part of your heating

system. It must be clean, the right size, properly

constructed and in

GOOD CONDITION.

No boiler

can function properly with a bad chimney.

1. Use local codes for installation or National Fuel

Gas Code Z223.1-latest revision. In Canada,

follow CSA B149.1 or .2 Installation Codes. It

is very important to properly size the venting

system for induced draft appliances. Consult

the

Vent Sizing Tables,

in the

National Fuel

Gas Code ANSI Z223

.1-latest revision for

correct sizing information. In Canada, consult

the Vent Sizing Tables, Amendment #1 to

CSA-B149.1 and .2 Installation Codes.

2. The boiler’s induced draft blower has a 3”

outlet. A 3” X 4” increaser fitting is included in

the parts bag. Locate the increaser fitting on the

outlet of the induced draft blower, and secure

gastight with a bead of the furnished silicone

sealant. The increaser fitting is required on

this boiler for Category I venting, and 4” is the

minimum permissible vent diameter. This does

not imply that the vent connector is intended to

be 4” diameter pipe. The vent connector shall

be sized according to the appropriate venting

Summary of Contents for XEB-2

Page 36: ...85 Middle Rd Dunkirk NY 14048 ...