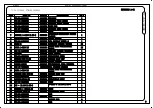

10

decrease the pressure. The standard work

pressure is 130 bar.

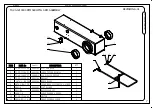

Chuck with 4 jaws can clamp any rim of 14~56″. To

the rim of 42~56″, we provide 4 extension rod can

be mounted on the jaw (See Fig 9)

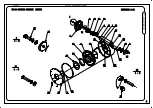

To the wheel of the diameter less than 800mm and

exceed 1500mm, you should insert the pin into the

second hole. (See the 11 in Fig23)

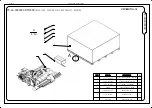

For the aluminum rim, we can provide 4 nylon

protective jaw mounted on the clamp. See Fig28.

Fig 28 Mount the nylon protective cover

The

nylon

protective

cover

should be mounted on the

aluminum alloy rim (Fig28)

Note: When mount/dismount the aluminum alloy

rim difficult to handle

,

you can place 2pins in the

hole of the terminal of the rim to avoid the nylon

protective cover sliding on the rim. See Fig 8

Dismount/mount wheel

:

wheel tubeless/ ring less coach car wheel

Completely deflate the wheel to be changed and

place on the carriage. Pay attention to the

construction of the rim. The small slope

termination rim should be outside, that is far away

from the chuck. Start the machine, use 4claws

clamp the center hole or any other suitable

position. Rise up the tool arm to the suitable height.

Move the carriage to the side far away from the

chuck. Contact the press disk on the tool head

against the termination of the tire. Continue

rotating the wheel and move the carriage towards

the tire to make the press disk be contacted with

the tire and then continue pressing for a little

distance. You can observe that there will be some

clearance at the position of the tire and rim

pressed by the press disk. Spread evenly a layer

of Vaseline Oil in the clearance. Continue rotate

and spread the oil until all the contact plane

between the rim and tire is spread with oil. Move

steeply rightward the carriage to make the press

disk about 200mm from the termination of the tire.

Rise up the mechanical arm and rotate the tool

head and move the carriage to the other side of

the tire and lower the mechanical arm and rotate

the chuck and steeply move the carriage to make

the press disk on the termination of the tire until

the entire tire is detached from the rim.

Mount the tire

A Use the chuck to clamp the rim and fix the tire

on the flange of the rim and keep it far away from

the chuck.

B Place the tire on the carriage and move the

carriage and rotation tool arm to insert the tire

pliers into the side of the tire hole. Rotate the

chuck to rise up the tire and use the press disk to

press the right termination of the tire to move the

tire leftwards to the proper position. At this

moment, one flange of the tire has been mounted

in the rim. Take off the tire pliers and continue

pressing the tire leftwards until the right side of the

tire into the right side of the rim and stop rotating

the chuck and mount the tire pliers on the press

disk. Rotate the chuck clockwise for a cycle to

complete the mount of the tire and detach the tire

pliers.

DTM590

DUNLOP GARAGE EQUIPMENT