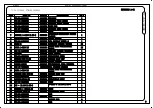

12

low.

valve

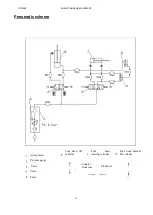

3. Settle

the

troubleshooting

of the hydraulic

system.

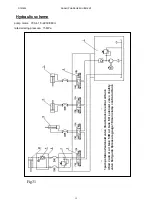

Hydraulic

part

of

hydraulic

system

and

machine

can

not

work

(

carriage,

tool

arm

and jaw

)

1. Rotation

direction

of

the

hydraulic oil pump

motor is not correct.

2. Thermal

over-load protective

device break

3. 24V fuse broken

1. Exchange

fuse in the plug;

2. Connect the

thermal over load

protector

3. Change fuse

The other technical troubleshooting should be

setled by the professional technicians authorized

!

Maintenance

The operators should always clean and

maintenance the machine.

The operators should maintenance the

equipments in reference to the methods described

in the instruction manual provided by the

manufacturer.

Before clean and maintenance, you should cut off

the power/pneumatic supply .

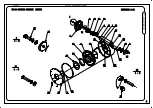

Mechanical maintenance

Periodically clean the chuck and carriage and

lubricate carefully with gun.

Check the oil level of the hydraulic power unit. Add

the wear resistance hydraulic oil with the viscosity

required.

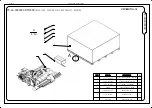

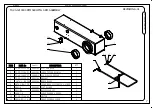

Transportation

The requirement to the rope or the methods to

hoist, see the Fig15 of this manual.

Note

:

Pull out the power plug and keep well the power

cord if long time no use of machine.

Repair

No matter which troubleshooting, handle as per

the methods listed on P12. The other

troubleshooting should be handled by the

professional personnel or contact with the dealer

or the manufacturer..

Remind

:

After the troubleshooting

happens and need repair, provide

the following information

A model of machine; B series number; C detail of

troubleshooting

Knowledge and note for the

repair and maintenance

Before any maintenance and repair, you should

cut off the power supply and air source to prevent

the accident to the operator of equipment and

the person responsible for the equipment should

periodically check and survey.

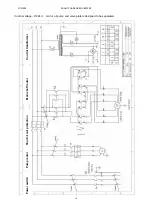

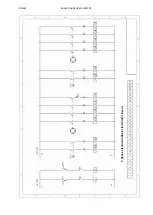

1

. The power supply must be grounded reliable.

2

.The oil cup of the air regulator should be filled

with the oil periodically and the oil feeding should

be adjusted. When the pneumatic part active for

4times, one drop of oil will be feed.

3、

You should secure the air supply pressure to

be 8-10bar

,

or the machine can not operate

normally.

4 、

Hydraulic power unit should use the

wear-resistant hydraulic oil N46. You should not

adopt the hydraulic oil of different chemical.

Change the hydraulic oil one time for the total time

to use the hydraulic oil reaches 600—800hours to

DTM590

DUNLOP GARAGE EQUIPMENT