202

z

Troubleshooting Guide

chap.6

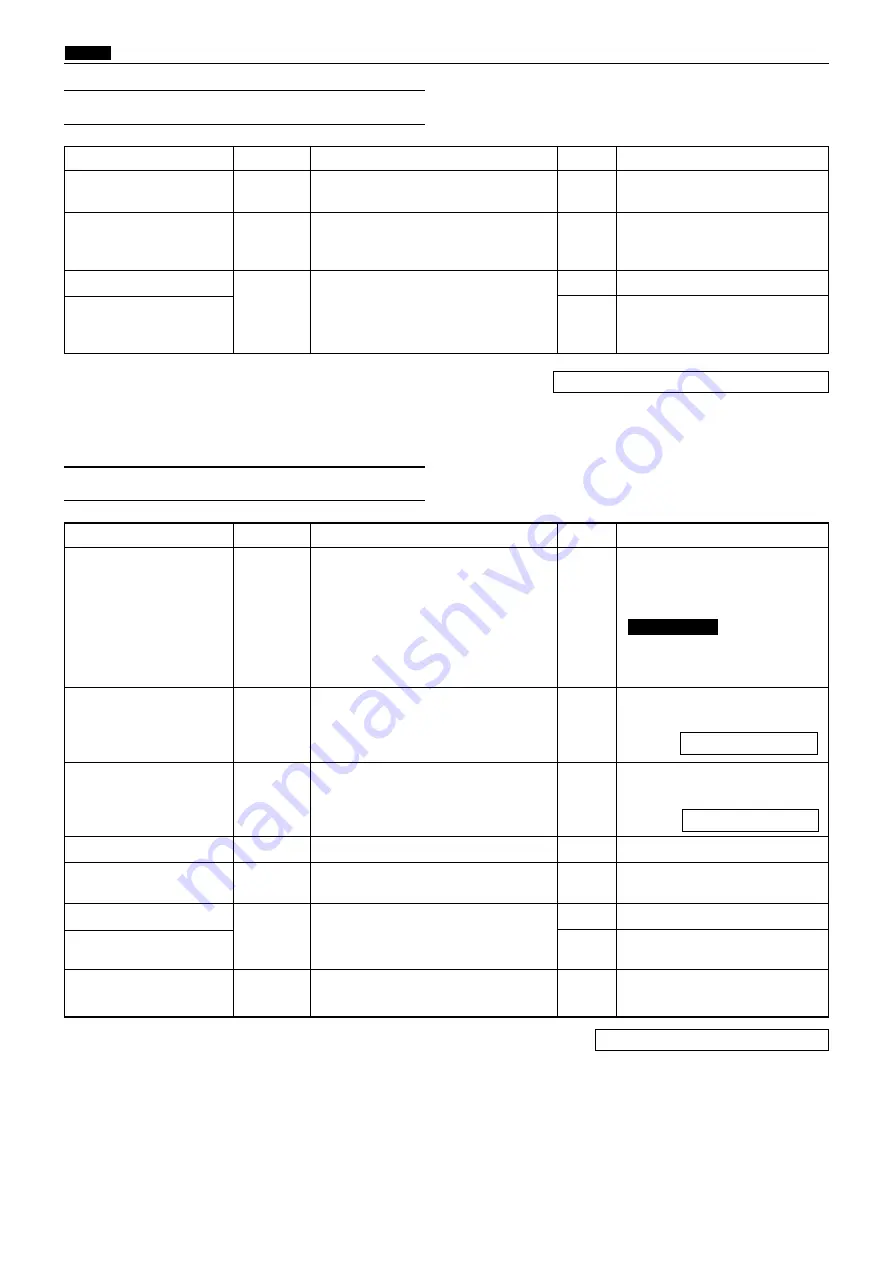

(13) "NO DRUM" is displayed

Cause/Defective section Procedures

Item to be checked

Result

Countermeasure

Drum setting.

1

YES

Finish.

Main PCB unit

2

YES

Check if drum SW is installed

in place and replace main PCB

unit.

Drum SW

3

NO

Replace drum SW.

Main PCB unit

YES

Check if drum SW is installed

in place and replace main PCB

unit.

Is trouble cleared by setting drum

again?

Does drum SW checked by HELP

mode (H-08)

*

prove to be normal?

Does drum SW checked by volt-ohm-

milliammeter prove to be normal?

HELP mode H-08

\

see p.236

*

(14) "MASTER SETTING ERROR" is displayed

Cause/Defective section Procedures

Item to be checked

Result

Countermeasure

End mark sensor PCB

1

NO

Adjust VR for end mark sensor

unit

by HELP mode (H-07)

*

. If un-

able,replace end mark sensor

PCB unit.

VR must be adjusted after

replacement of end mark sensor

PCB unit.

Master feeding clutch

2

NO

Refer to “(15) Malfunction of master

feeding clutch”.

Master stepping motor

3

NO

Refer to “(16) Malfunction of

master stepping motor”.

Cutter unit

4

NO

Replace cutter unit.

Static electricity

5

YES

Remove static-eliminating brush.

Master

6

YES

Finish.

Transfer path

NO

Remove any foreign matter in

transfer path.

Master attach position

7

NO

Adjust the master attach position.

IMPORTANT:

Has “MASTER SETTING ERROR”

actually occurred?

Does master feeding clutch operate

normally?

Does master stepping motor operate

normally?

Is master cut normally?

Is static-eliminating brush on master

feeding unit damaged or deteriorated?

Is trouble cleared by replacing mas-

ter?

Is the master attach position within

reference value?

HELP mode H-07

\

see p.234

*

\

see page 203

\

see page 203

Summary of Contents for Duprinter DP-330

Page 9: ......

Page 11: ......

Page 18: ...c Dimensions chap 1 17 MEMO...

Page 24: ...4 8 2A 2B 2C 44000A1e b Part Names and Their Functions chap 1 23...

Page 152: ...151 MEMO...

Page 193: ...192 MEMO...

Page 329: ...328 x Overall Wiring Layout chap 8 15 Overall Wiring Layout 2 Drive PCB 2 2...