40

x

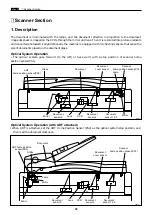

Platemaking / Master Feed / Ejection Section

chap.2

x

Platemaking / Master Feed / Ejection Section

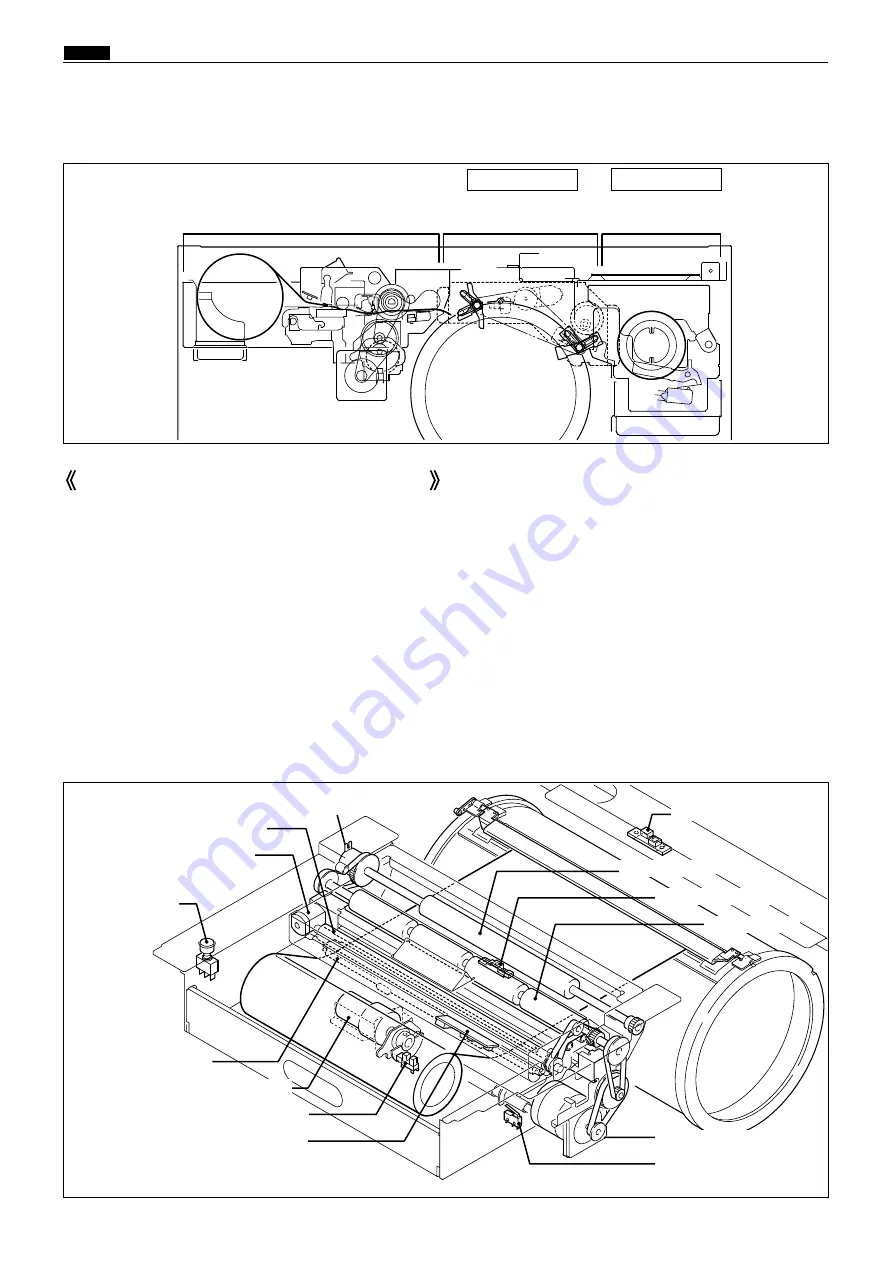

Make the master clamp of the drum unit clamp the master top end, performing platemaking on the master

with the thermal head. (In this machine, the master on the drum is ejected at the same time when

platemaking is performed.)

The master is conveyed to the drum unit via the platen roller and sponge roller1,2 by driving of the master

feed stepping motor, while it is being processed in the thermal head section. Sponge roller2 is driven through

the master feed clutch (electromagnetic clutch), and controls the amount of master conveyed to the master

clamp section of the drum unit with the master feed clutch ON / OFF.

The end mark sensor starts to detect when the end mark (black) section printed on the end of the roll master

is conveyed.

"CHANGE MASTER"

is displayed on the LCD panel. The end mark sensor also detects whether

the master is conveyed properly through the sensor.

Cutter unit

Master feed clutch

Sponge roller 2

Master detect sensor

Master cover switch

Platen roller

Master roll cat

switch

Thermal head

Master feed stepping motor

End mark sensor

1. Description

Platemaking / Master Feed Section

Platemaking / Master Feed section

Master Clamp Opening /

Closing Section

Master Ejection Section

See page 52

See page 54

440315

440314

Thermal head up/down motor

Thermal head position sensor

Sponge roller 1

Master top sensor

Summary of Contents for Duprinter DP-330

Page 9: ......

Page 11: ......

Page 18: ...c Dimensions chap 1 17 MEMO...

Page 24: ...4 8 2A 2B 2C 44000A1e b Part Names and Their Functions chap 1 23...

Page 152: ...151 MEMO...

Page 193: ...192 MEMO...

Page 329: ...328 x Overall Wiring Layout chap 8 15 Overall Wiring Layout 2 Drive PCB 2 2...