Timing

If the variation in the amount of light received by

the master ejection sensor during the making of 1

plate is less than a certain level (8 in the HELP06

display value), a plate ejection error is deemed to

have occurred.

53

x

Platemaking / Master Feed / Ejection Section

chap.2

2. Rotation Control of the Eject (Roll-up) Motor

If the eject motor is kept rotating when the master tip end is pulled to the ejection box in the plate

detachment process, the drum is actuated by the master and the stop position slips. To prevent this, the

eject motor is stopped when the master is detected by the master ejection sensor. (If the master is not detected

by the master ejection sensor, the eject motor is stopped by the timer.)

(1) Master Ejection Sensor

Description

Photo-emission from the master ejection sensor is

received on the master ejection sensor, and the

sensor detects with the photo strength whether the

master is pulled to the master ejection box.

Photo-receiving amount is checked with the

HELP06.

1. Master Ejection Error Detection

Operation

While one platemaking is being processed, the difference of photo-receiving amount is less than 8 by checking

with the HELP5, which is determined as an master ejection error. The following display and operation are

shown.

2

"PLATE EJECTION ERROR"

is displayed on the LCD panel and printing is not processed.

2

"PLATE EJECTION ERROR"

is cleared with the

ALL CLEAR

key ,

STOP

key pressed.

2

A master ejection error is not detected for one platemaking soon after a plate ejection error or master

setting error is detected.

¡

If incorrect sensing occurs due to sensor malfunction, etc., HELP32 can be used to

prohibit plate ejection error sensing.

IMPORTANT :

Smaller

Larger

Photo-receiving amount

3. Function of Parts

HELP mode H-32

\

see p.261

HELP mode H-06

\

see p.232

HELP mode H-06

\

see p.232

2

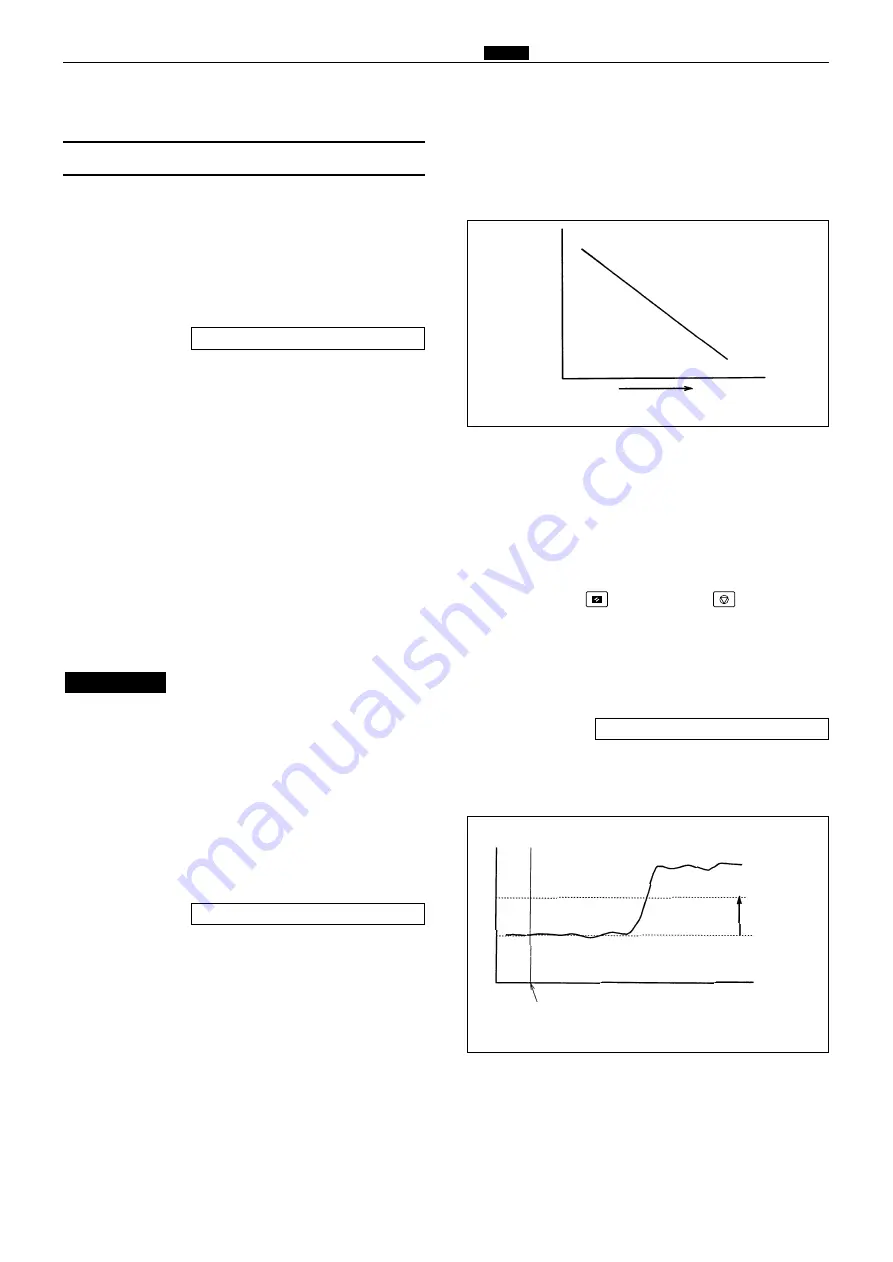

HELP mode H-06 value

00

63

2

HELP mode H-06 value

Value without master : the photo receiving amount of

the master ejection sensor at the position where the

first paper jam is detected after starting platemaking.

00

Threshold value

63

Threshold value :

Value without 8

Time

Summary of Contents for Duprinter DP-330

Page 9: ......

Page 11: ......

Page 18: ...c Dimensions chap 1 17 MEMO...

Page 24: ...4 8 2A 2B 2C 44000A1e b Part Names and Their Functions chap 1 23...

Page 152: ...151 MEMO...

Page 193: ...192 MEMO...

Page 329: ...328 x Overall Wiring Layout chap 8 15 Overall Wiring Layout 2 Drive PCB 2 2...