71

c

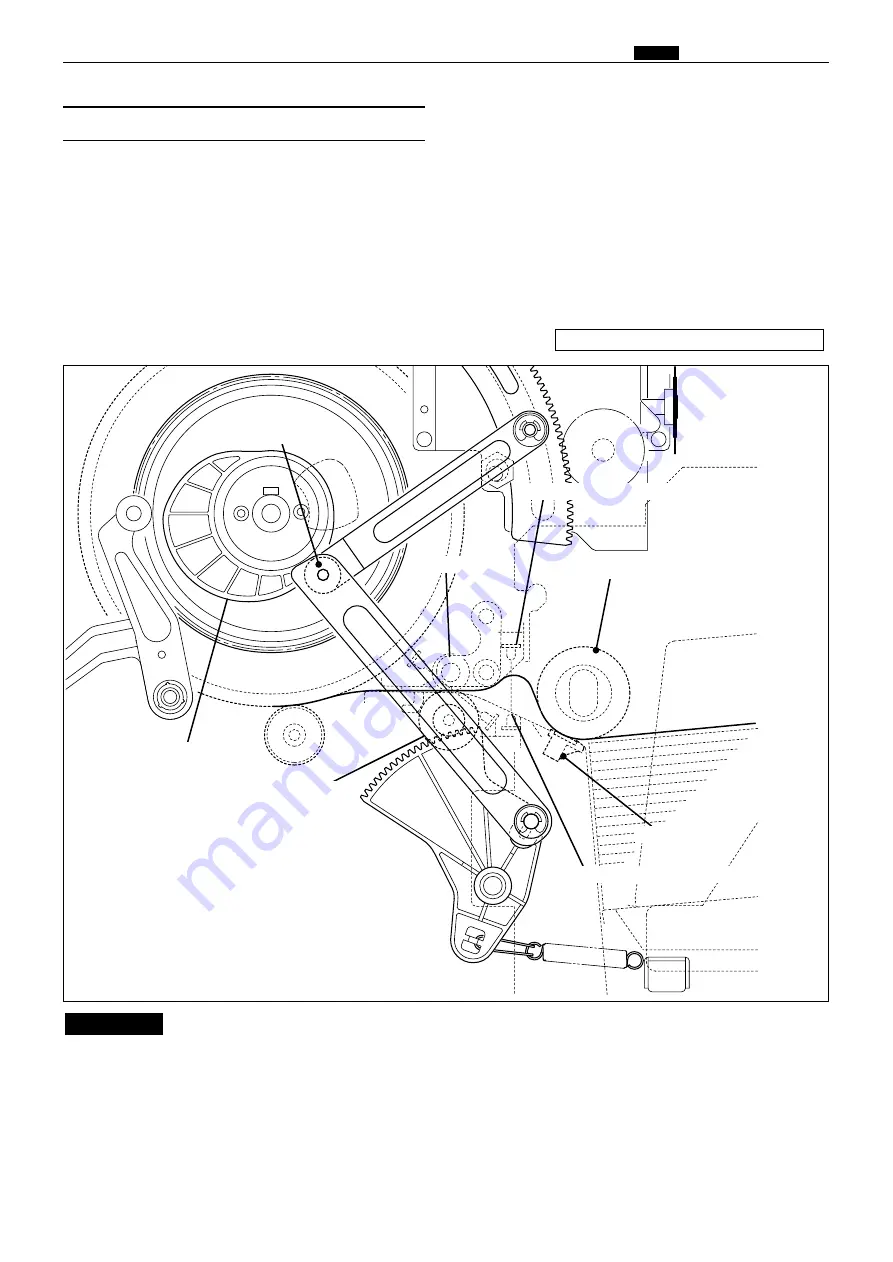

Paper Feed Section

chap.2

The “paper feed length” is the length by which the paper feed roller feeds out the print paper. When the paper

feed roller feeds out the print paper, the guide roller is pressed against the timing roller and does not rotate;

as a result, the paper arches up between the paper separator and the timing roller, since the distance between

these two items is only 80mm, while the length by which the paper is fed out from the paper feed roller is

95mm. This arching has the effect of correcting any skewing of the paper (as the leading edge is held firm

between the guide and timing rollers). It also has the effect of lessening the load on the timing roller when it

feeds the paper through, thus minimizing slippage.

For feed amount, the leading edge of the paper is detected by the paper feed length sensor and paper feed is

controlled by program(

HELP mode H-86,88

).

HELP mode H-86,88

\

see p.308,309

¡

If paper feed length is too large: the arching dimension will be too large, and if the paper is

of a very stiff type, it will buckle up between the paper feed roller and the paper feed inlet

(upper), causing a PAPER JAM error ("PAPER JAM ON THE FEEDER SIDE").

¡

If paper feed length is too small: the arching dimension will be too small, so that arching

will be unable to correct skewing of the paper, and skewing and wrinkling will be liable to

occur. Furthermore, the slippage that occurs when the timing roller feeds the paper

through will be very large, resulting in printing position errors.

IMPORTANT :

(5) Paper Feed Length

Cam follower

Paper feed cam

Paper feed roller

Guide roller

Paper separator

Timing roller

440306

Paper top detect sensor

Double feed detect sensor

Summary of Contents for Duprinter DP-330

Page 9: ......

Page 11: ......

Page 18: ...c Dimensions chap 1 17 MEMO...

Page 24: ...4 8 2A 2B 2C 44000A1e b Part Names and Their Functions chap 1 23...

Page 152: ...151 MEMO...

Page 193: ...192 MEMO...

Page 329: ...328 x Overall Wiring Layout chap 8 15 Overall Wiring Layout 2 Drive PCB 2 2...