2

33

Creaser Modules

Before Using This Machine

1

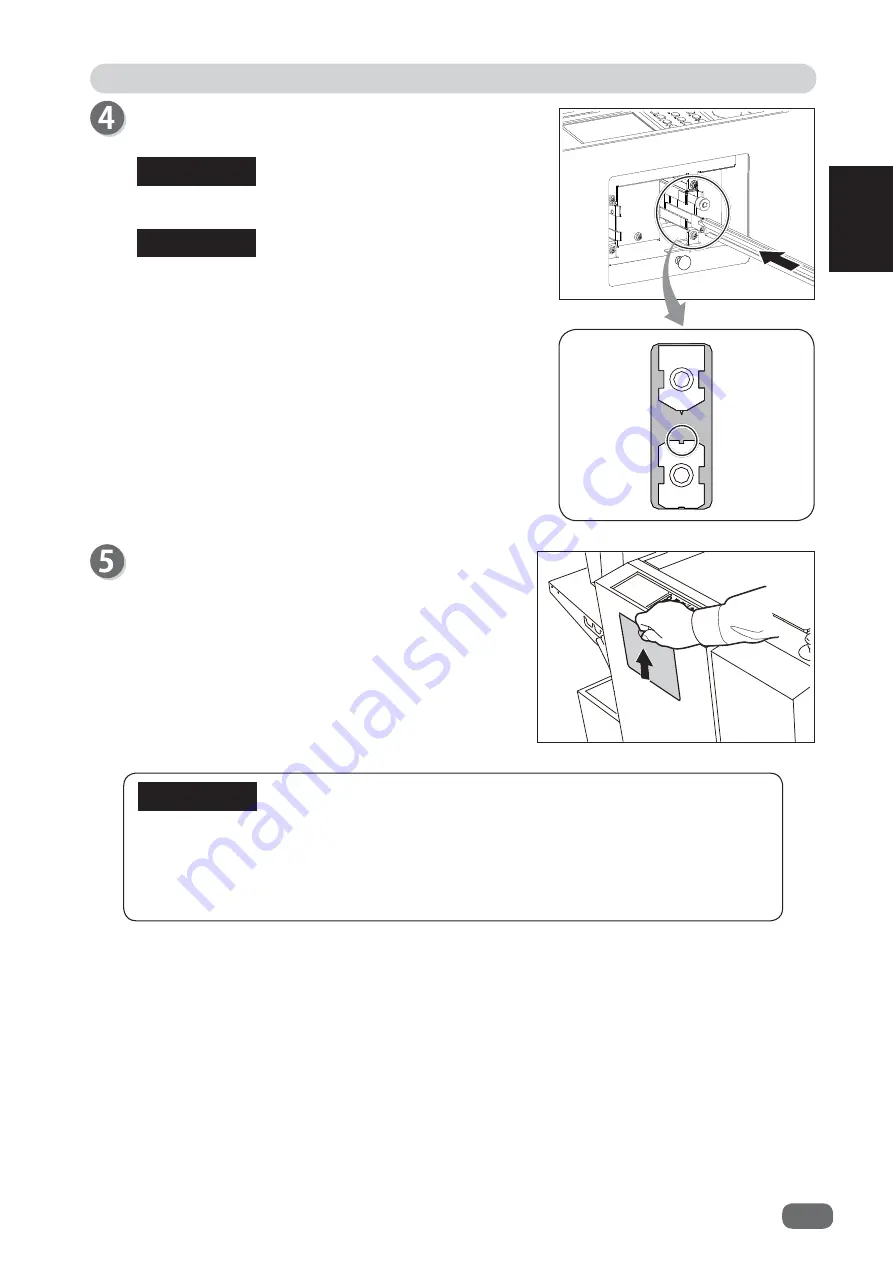

Insert the

creaser concave tool

in the position in the

fi

gure.

Insert the tool securely until it stops.

The creaser concave tool is shaped narrower for

light weight documents and wider for heavy weight

documents.

Make sure to insert it so that the proper groove faces

upward.

Hold the

knob

and close the

insert cover

.

REFERENCE

IMPORTANT

Do not run the DC-516 without

creaser tools

(convex and concave tools) while the

creaser module

is installed in it.

Be sure to pull them out before removing the

creaser module

from the DC-516.

You cannot remove the

creaser module

with the

creaser tools

(convex and concave

tools) attached to it.

IMPORTANT

Summary of Contents for DC-516

Page 1: ......

Page 2: ......

Page 137: ...119 Appendix Appendix This chapter lists an index Index 120...

Page 141: ......

Page 142: ......