1-23

12H-M12M0-0309-0

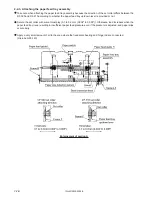

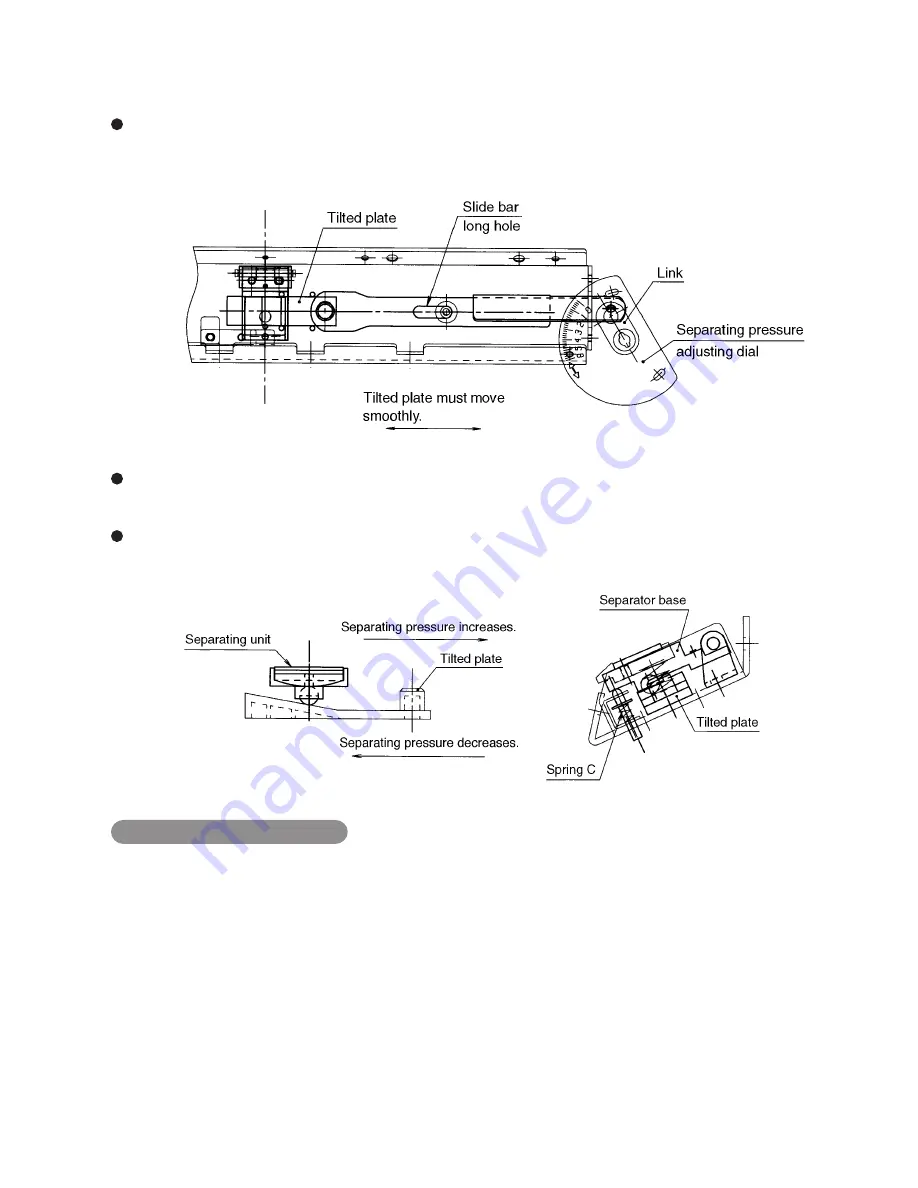

2-3. Separating Mechanism

The separating mechanism is more or less the same as the DF-520N.

The separating pressure can be set in seven steps from 0 to 6 to handle special coated paper. For this reason, the

separator base is located on the tilted plate to which it is connected by the link mechanism. When the separating

pressure adjusting dial is rotated, the tilted plate moves and forced pressure is applied to the separator base.

When the separating pressure scale value is standard “0”, the forced pressure is released, and only pressure of

spring C (approximately 120 g) is applied to the separator base.

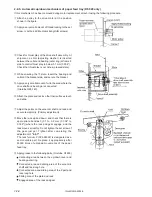

When the separating pressure adjusting dial is rotated, forced pressure is applied to the separator base if the scale

value is within 3.5 (design value is 2.5).

Setting the separating pressure

When using normal paper, set the separating pressure to standard “0”, and increase 0.5 at a time if double-feed

occurs. For coated paper, set the separating pressure to “2.5 to 3.5”. However, first set to “2.5” and increase 0.5 at a

time if double-feed occurs.

Using at a high separating pressure from the beginning causes problems such as paper jam at the separator and

abnormal wear of the paper feed ring.