1-32

12H-M12M0-0309-0

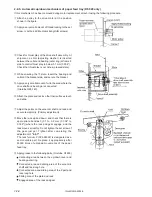

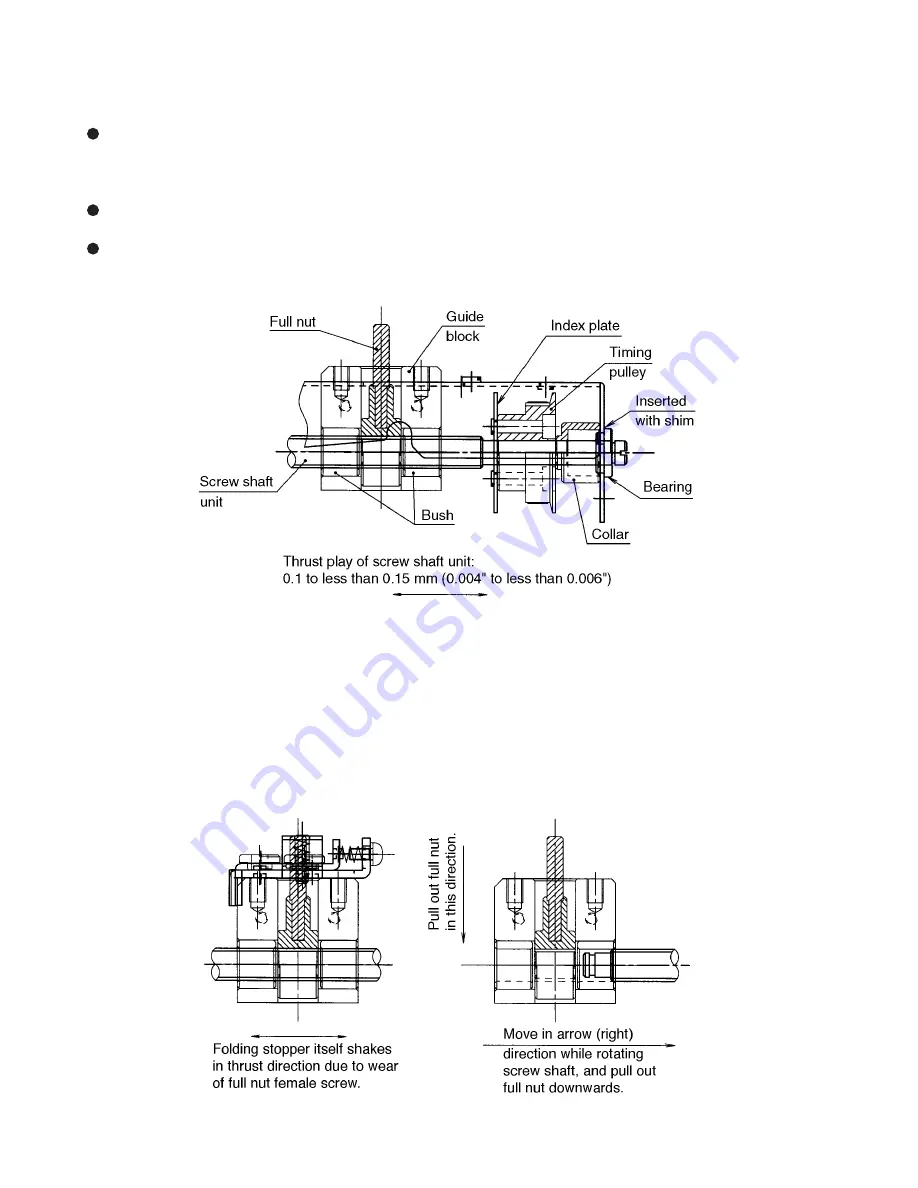

2-6-2. Checking and adjusting the thrust play of the screw shaft unit

Check the following points when folding misalignment along the vertical length of the paper and folding plate motor

lock occurs.

Check that a shim is inserted between the chassis and bearing at the folding plate motor side so that the thrust play

of the screw shaft unit becomes 0.1 to less than 0.15 mm (0.004" to less than 0.006"), and that the unit moves lightly

and smoothly.

Apply a very small amount of oil to the area where the screw shaft and bearing are connected. (Orelube G90-140)

To prevent folding plate motor lock, never apply oil or grease to the sliding area where the screw shaft, full nut, and

guide block bush are connected.

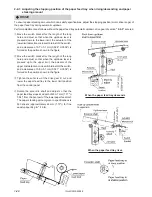

2-6-3. Replacing the full nut

If the female screw of the full nut (resin) wears due to extended use, thrust play between the screw shaft and full nut

increases, resulting in reduced folding stopper stop accuracy and increased folding misalignment along the vertical

length of the paper due to play of the folding stopper itself.

When these problems occur, replace the full nut.

The full nut cannot be replaced by merely pulling it upwards because the screw is cut on the whole block

circumference for higher durability. Rotate the screw shaft as shown in the figure, move in the right direction, and pull

the full nut downwards.