1-33

12H-M12M0-0309-0

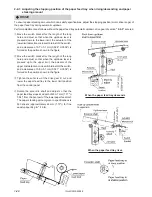

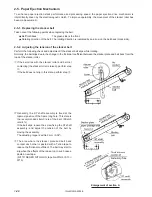

2-6-4. Motor deceleration pulley assembly

If the tension of the belt is not appropriate, problems such as folding plate motor lock and jumping of the belt occur.

q

Tighten the set screw with a torque of 0.69 Nm (7.0

kgf • cm), and secure the motor pulley at the position

shown in the figure.

w

Check that a shim is inserted between the idler pulley

and E ring so that the thrust play becomes 0.1 to 0.3

mm (0.004" to 0.012").

e

Apply a very small amount of oil to the area where the

idler pulley and fulcrum pillar are connected.

(Orelube G90-140)

r

Apply a pressure of 3 N (306 gf) to deceleration

timing belt 1 using a tension gauge of 5 N (510 gf),

and check that the belt slacks by 2 to 3 mm (0.08" to

0.12").

t

Apply a pressure of 3 N (306 gf) to deceleration

timing belt 2 using a tension gauge of 5 N (510 gf),

then move the motor deceleration pulley assembly

and adjust the tension of the belt so that it slacks by 2

to 3 mm (0.08" to 0.12").