Reviews:

No comments

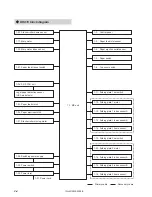

Related manuals for DF-915

Astro

Brand: Necta Pages: 13

Ellageo PLUS BLL2

Brand: Baby Lock Pages: 43

Diana BL480A

Brand: Baby Lock Pages: 71

BL50A

Brand: Baby Lock Pages: 2

BL50A

Brand: Baby Lock Pages: 2

A_LINE Maria BL23A

Brand: Baby Lock Pages: 78

A-LINE Natalie BL18A

Brand: Baby Lock Pages: 70

A-LINE Lauren BL450A

Brand: Baby Lock Pages: 12

Aventura BLMAV

Brand: Baby Lock Pages: 204

Aventura BLMAV

Brand: Baby Lock Pages: 24

Elissimo & Elissimo GOLD BLSO-BF2

Brand: Baby Lock Pages: 22

138W101

Brand: Singer Pages: 12

C85 2018 BS NSC BASIC

Brand: COMAC Pages: 32

N291

Brand: Duerkopp Adler Pages: 95

mma-250/3

Brand: Zenit Powertools Pages: 10

BLIZZARD BLAST

Brand: Jennison Entertainment Technologies Pages: 17

H-Type 969

Brand: DURKOPP ADLER Pages: 90

66-2100

Brand: Sandia Pages: 2