36

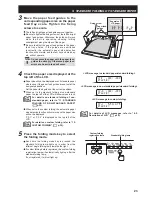

Set the folding stopper positions of

folding plates 1 and 2.

Press the “+” key of the folding plate 1 folding stopper

adjusting key and move the folding stopper to the

measured dimensions A (3.35") of the sample.

Press the “+” key of the folding plate 2 folding stopper

adjusting key and move the folding stopper to the

measured dimensions B (3.74") of the sample.

The position moved to by the folding stopper is

displayed in inch on the LCD.

5

12. CUSTOM FOLDING

Stacker roller

Paper ejection section cover

CF-1 3.35/3.74

STAND BY

Set the position of the stacker roller.

The position of the stacker roller needs to be changed

according to the folded paper length.

Selecting and pressing a numerical key (1 to 6) while

pressing the stop key moves the stacker roller to the

position set.

Refer to the following table for approximate set

positions.

In this example, the folded paper length C is 4.33".

Therefore press the numerical key 3 while pressing

the stop key.

6

Numerical

key setting

1

2

3

4

5

6

Folded paper

length

To 3.35"

3.36" to 4.13"

4.14" to 4.72"

4.73" to 5.31"

5.32" to 5.91"

From 5.92"

Approximate stacker roller set position

Checking the stacker roller position

Press the No. of sheets/Paper length key while pressing

the stop key. The LCD shows the position of the stacker

roller in the value set using the numerical key.

Opening/closing the paper ejection section cover

Set the position of the stacker roller by opening the paper ejection section cover, and checking the movement of the stacker

roller visually.

After setting, be sure to close the paper ejection section cover. If not closed, operating the test key or start key shows

“DELIVERY COVER” on the LCD, and this unit will not operate.

CF-1

3.35/3.74

STAND BY

CF-1

3.35/3.74

STACKER ROLLER:3