Page 7

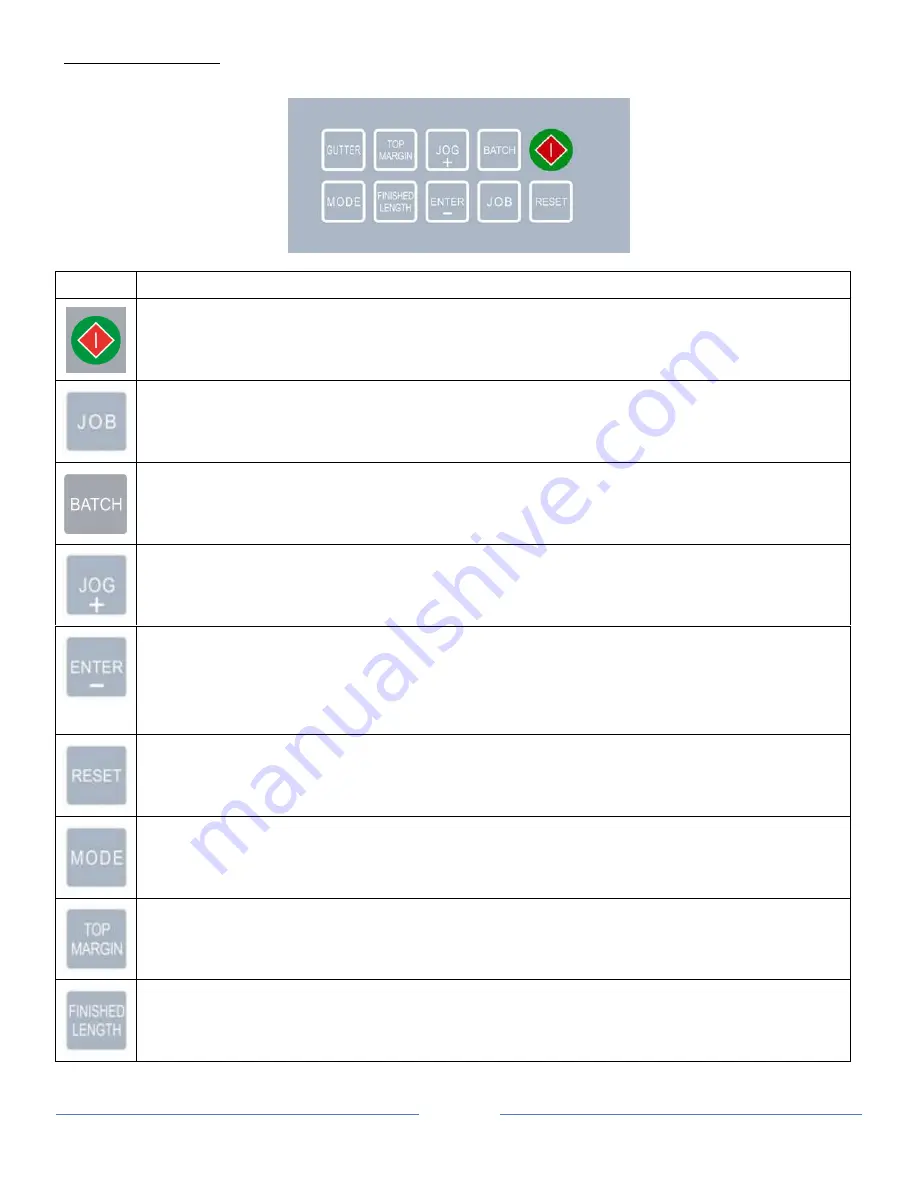

CONTROL PANEL

Keys

Function

•

Start and Stop the cutter

•

Change job

•

Toggle between “Normal Mode” and “Turbo Mode” (Paper Weight Setting Mode)

•

Select batch count

•

Pre-feed (Mark Reader Calibration Mode)

•

Jog forward

•

Increment settings by 0.1 mm when press.

•

Confirm job and batch count setting.

•

Decrement settings by 0.1mm when press (Mark Reader Calibration Mode).

•

Jog backward

•

Reset counter (use with “RESET” button simultaneously)

•

Save settings

•

Hold (4s) paper weight setting mode

•

Reset counter (use with “ENTER” Button simultaneously)

•

Enter program mode

•

Change paper weight

•

Set top margin

•

Set finished length