124

n

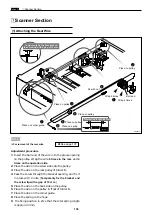

Paper Ejection Section

chap.3

1.

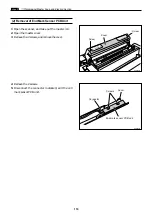

Remove the paper ejection base.

2.

Remove the paper ejection belts.

3.

Remove the 4 screws indicated, and remove the

base plate.

\

See page 123

(4) Removal of Paper Ejection JAM Sensor

(3) Removal of Paper Ejection Belt

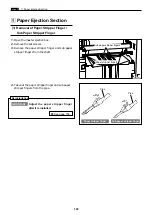

1.

Remove the paper ejection base.

2.

Remove the 2 screws from the static removal

brush.

3.

Remove the 2 screws from the static removal

bracket.

4.

Remove the timing belt.

\

See page 123

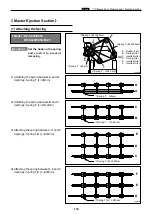

5.

Stretch the belts and install them oriented as

shown in the figure.

Screw

R8S03073

R8S03076a

Static removal brush

Timing belt

Guide plate

Screws

Static removal bracket

R8S03075

Timing belt

Screws

Base plate

R8S03076b

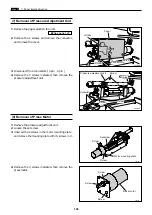

Paper ejection

jam sensor

Connector

Sensor angle

Screw

Paper ejection belts

4.

Remove the screw indicated, and remove the

sensor angle.

5.

Remove the screw and disconnect the connector,

and remove the paper ejection jam sensor.

Do not mistake installation directions

of the paper ejection jam sensor.

IMPORTANT :

Reinstallation

Screw

Screw

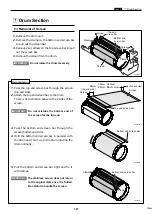

Summary of Contents for DP-S Series

Page 1: ......

Page 9: ......

Page 11: ......

Page 16: ...x Dimensions chap 1 15 R8S01001 xDimensions 622 1360 510 228 1080 710 980 688 370 mm...

Page 22: ...v Part Names and Their Functions chap 1 21 44000A1e 2A 2B 2C R8S01006a 2Detailed drawing...

Page 33: ...32 z Scanner Section chap 2 Circuit R8S02E03e...

Page 87: ...86 m Drum Section chap 2 2 Circuit R8S02E30...

Page 171: ...170 MEMO...

Page 193: ...192 MEMO...

Page 195: ...194 z Help mode List chap 7 z HELP Mode List...

Page 243: ...242 c HELP Mode Function and Operation Procedures chap 7...

Page 270: ...269 c HELP Mode Function and Operation Procedures chap 7...

Page 281: ...280 MEMO...

Page 293: ...292 z Electrical Parts Layout and Their Functions chap 9 MEMO...

Page 295: ...309 294 x Overall Wiring Layout chap 9 Overall Wiring Layout 1 Main PCB 2 2...

Page 297: ...311 296 x Overall Wiring Layout chap 9 Overall Wiring Layout 2 Drive PCB 2 2...