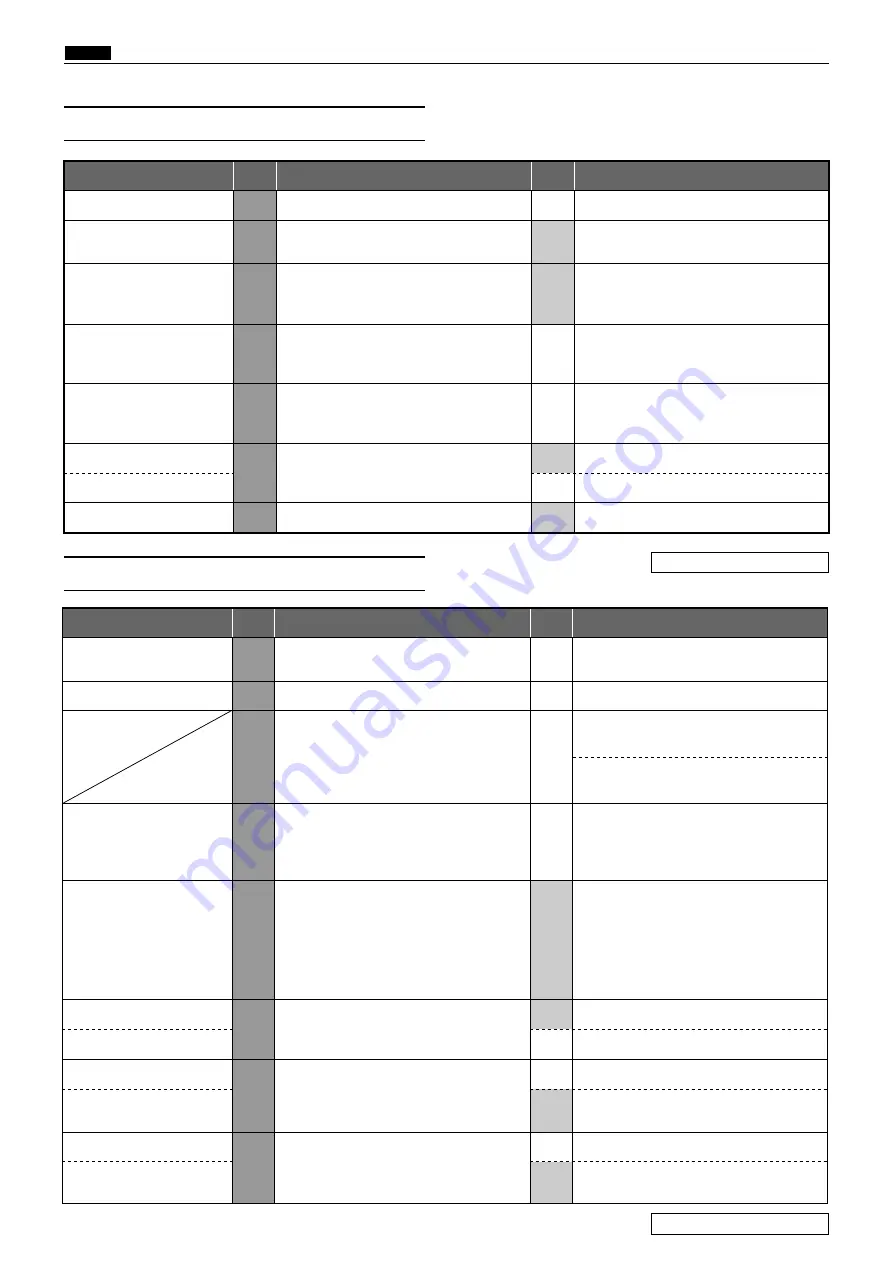

(3) "E001" is displayed

174

z

Troubleshooting Guide

chap.6

(4) "E002" is displayed

Cause/Detective section Procedures

Result

Countermeasure

Items to be checked

Feed tray operation is

defective

1

Is the feed tray moved by hand

smoothly?

Remove the cause of defective operation.

Lean or catch?

3

2

Check with the HELP-006. Are the

elevator top limit sensor and the

elevator lower limit switch normal?

NO

NO

NO

Follow the procedure

7

when the

elevator top limit sensor is defective.

Follow the procedure

8

when the

elevator lower limit switch is defective.

24V power supply

4

Measure the voltage between CN2-5

and CN2-1 of the 24V power with the

tester. Is the v24V?

NO

Measure the voltage between CN1-1 and

CN1-3 of the 24V power with the tester.

If it is AC100V, replace the 24V power.

Elevator motor

Fuse

5

At the timing when the elevator motor

operates, measure the voltage between

CN3-9 and CN3-10 of the drive PCB

with the tester. When inserting and

removing the relay connector of the

elevator motor, is +24V or -24V applied?

YES

Check the wiring harness. If there is

no problem, replace the elevator motor.

Replace the fuse.

Drive PCB Unit

6

Does replacing the drive PCB unit solve

the problem?

Is the fuse of the drive PCB normal?

YES Finish.

Main PCB Unit

NO

Replace the main PCB Unit.

Elevator top limit sensor

7

Turn ON/OFF the elevator top limit sensor

for measurement with the tester. Is the

sensor normal?

Replace the elevator top limit sensor.

Main PCB Unit

Check the wiring harness. If there is

no problem, replace the main PCB.

8

Elevator lower limit switch

Turn the elevator lower limit switch on and

off, and use a tester to measure voltage.

Is voltage normal?

NO

Replace the elevator lower limit switch.

Main PCB Unit

YES

NO

YES

Check the wiring harness. If there is

no problem, replace the main PCB.

Cause/Detective section Procedures

Result

Countermeasure

Items to be checked

1

Does drum rotate?

Proceed to procedure

5

.

NO

Drum

2

Drum interference with

the main unit

3

Does main motor rotate without drum?

YES Eliminate interference.

Main motor encoder

sensor

5

Does the main motor encoder sensor status

when it is checked using HELP-005?

NO

24V power supply

Measure the voltage between CN2-6

and CN2-2 of the 24V power with the

tester. Is the v24V?

NO

Measure the voltage between CN1-1 and

CN1-3 of the 24V power with the tester.

If it is AC100V, replace the 24V power.

Main motor PCB unit

6

7

Does replacing the main motor PCB unit

solve the problem?

Is there any problem in the above items?

NO

Finish.

Main PCB unit

Main motor

YES

YES

Replace the main PCB unit.

Replace the main motor.

Replace the main motor encoder sensor.

If the main motor encoder sensor does not operate

even after replacement, replace the main PCB.

4

Does main motor rotate without the

driving timing belt?

Drive system gear broken

or blocked with foreign

matter.

Check if drive system gear is broken

or blocked with foreign matter and

remove cause.

YES

HELP-005

\

see page 207

HELP-006

\

see page 211

Summary of Contents for DP-S Series

Page 1: ......

Page 9: ......

Page 11: ......

Page 16: ...x Dimensions chap 1 15 R8S01001 xDimensions 622 1360 510 228 1080 710 980 688 370 mm...

Page 22: ...v Part Names and Their Functions chap 1 21 44000A1e 2A 2B 2C R8S01006a 2Detailed drawing...

Page 33: ...32 z Scanner Section chap 2 Circuit R8S02E03e...

Page 87: ...86 m Drum Section chap 2 2 Circuit R8S02E30...

Page 171: ...170 MEMO...

Page 193: ...192 MEMO...

Page 195: ...194 z Help mode List chap 7 z HELP Mode List...

Page 243: ...242 c HELP Mode Function and Operation Procedures chap 7...

Page 270: ...269 c HELP Mode Function and Operation Procedures chap 7...

Page 281: ...280 MEMO...

Page 293: ...292 z Electrical Parts Layout and Their Functions chap 9 MEMO...

Page 295: ...309 294 x Overall Wiring Layout chap 9 Overall Wiring Layout 1 Main PCB 2 2...

Page 297: ...311 296 x Overall Wiring Layout chap 9 Overall Wiring Layout 2 Drive PCB 2 2...