218

c

HELP Mode Function and Operation Procedures

chap.7

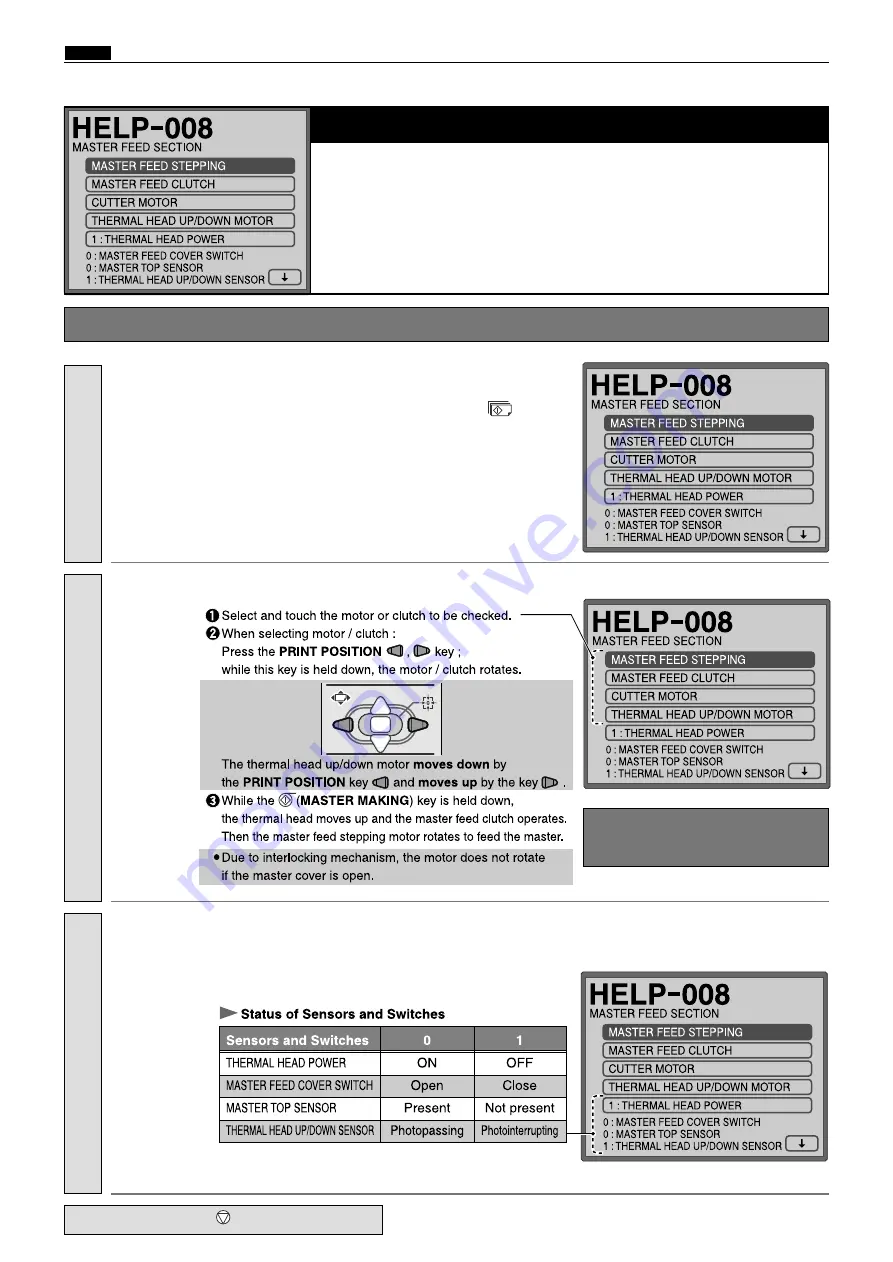

(1) Adjusting/Checking the master feed section

(2 pages in total)

Page 1 :

2

Check operation.

MASTER FEED STEPPING MOTOR / MASTER FEED CLUTCH / CUTTER MOTOR /

THERMAL HEAD UP/DOWN MOTOR

2

Checking sensors/switches.

MASTER FEED COVER SWITCH / MASTER TOP SENSOR / THERMAL HEAD UP/DOWN SENSOR

¡

Operation procedure

1.

3.

Check the following sensors and switches.

Checking sensors/switches.

2.

Check operation.

¡

After checking the cutter motor

operation, be sure to return the

cutter blade to the operation side.

step 4.

a

Press the

(STOP)

key.

Enter

“

008

”

by the

NUMERIC

keys and then press the

(PRINT)

key.

Call the HELP mode “H-008”.

Summary of Contents for DP-S Series

Page 1: ......

Page 9: ......

Page 11: ......

Page 16: ...x Dimensions chap 1 15 R8S01001 xDimensions 622 1360 510 228 1080 710 980 688 370 mm...

Page 22: ...v Part Names and Their Functions chap 1 21 44000A1e 2A 2B 2C R8S01006a 2Detailed drawing...

Page 33: ...32 z Scanner Section chap 2 Circuit R8S02E03e...

Page 87: ...86 m Drum Section chap 2 2 Circuit R8S02E30...

Page 171: ...170 MEMO...

Page 193: ...192 MEMO...

Page 195: ...194 z Help mode List chap 7 z HELP Mode List...

Page 243: ...242 c HELP Mode Function and Operation Procedures chap 7...

Page 270: ...269 c HELP Mode Function and Operation Procedures chap 7...

Page 281: ...280 MEMO...

Page 293: ...292 z Electrical Parts Layout and Their Functions chap 9 MEMO...

Page 295: ...309 294 x Overall Wiring Layout chap 9 Overall Wiring Layout 1 Main PCB 2 2...

Page 297: ...311 296 x Overall Wiring Layout chap 9 Overall Wiring Layout 2 Drive PCB 2 2...