87

m

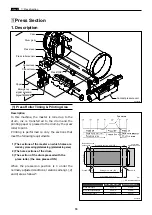

Drum Section

chap.2

Description

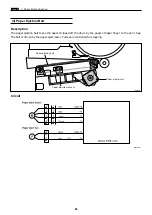

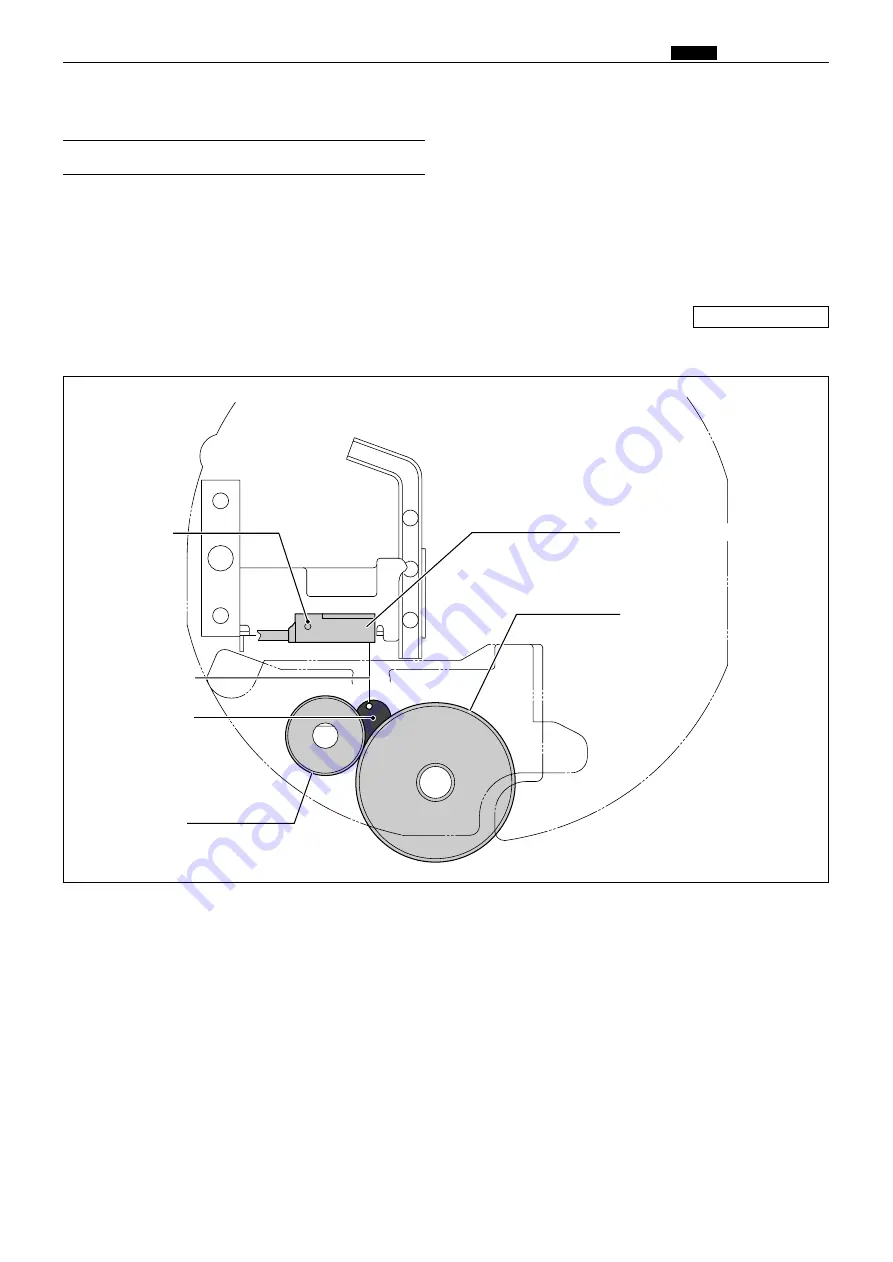

The ink amount variation in the ink control section is read by the electric capacity variation between the

detection needles on the ink detection PCB Unit and the GND and the ink signal is output to the main PCB

Unit. The main PCB Unit controls the ink pump motor ON and OFF by this signal.

When

NO INK

continues while the drum rotates 20 times (speed 3*) during printing, it is determined that the

ink pack is empty,

"NO INK"

is displayed and the machine stops printing.

(* the number of drum unit rotations; it varies depending on the printing speed.)

(1) Ink Detection

3. Function of Parts

\

See page 89

R8S02078

Ink detection PCB unit

LED

Squeegee roller

Ink roller

Ink

Detection needle

Summary of Contents for DP-S Series

Page 1: ......

Page 9: ......

Page 11: ......

Page 16: ...x Dimensions chap 1 15 R8S01001 xDimensions 622 1360 510 228 1080 710 980 688 370 mm...

Page 22: ...v Part Names and Their Functions chap 1 21 44000A1e 2A 2B 2C R8S01006a 2Detailed drawing...

Page 33: ...32 z Scanner Section chap 2 Circuit R8S02E03e...

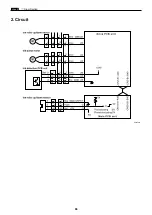

Page 87: ...86 m Drum Section chap 2 2 Circuit R8S02E30...

Page 171: ...170 MEMO...

Page 193: ...192 MEMO...

Page 195: ...194 z Help mode List chap 7 z HELP Mode List...

Page 243: ...242 c HELP Mode Function and Operation Procedures chap 7...

Page 270: ...269 c HELP Mode Function and Operation Procedures chap 7...

Page 281: ...280 MEMO...

Page 293: ...292 z Electrical Parts Layout and Their Functions chap 9 MEMO...

Page 295: ...309 294 x Overall Wiring Layout chap 9 Overall Wiring Layout 1 Main PCB 2 2...

Page 297: ...311 296 x Overall Wiring Layout chap 9 Overall Wiring Layout 2 Drive PCB 2 2...