DUPLOMATIC E.M.DDC4-400V/RK RELEASE 1.9 07-09

EM DDC4-400-RK-0709gb.doc

14

OPERATING FUNCTION N°4: JOG

The disc will rotate of one step in the selected direction.

Proceed as follows

1. Clear all alarms (if present);

2. Set the operating function:

INPUTS

OPERATING FUNCTION N°4:

MODE01 MODE02 MODE03

Next station in CW or CCW

0 0 1

3. Select

direction:

PBIT01

PBIT02

Rotation in CW

1 0

Rotation in CCW

0 1

4. Set

PSTART

for give the confirmation of the movement in 5 s.

(It must stay ON for more than 30 ms).

OPERATING FUNCTION N°5: SERVICE

The turret cycle can be executed “step by step”: unlocking, rotation, locking.

Proceed as follows

1. Clear all alarms (if present);

2. Set an operating function:

INPUTS

OPERATING FUNCTION N°5:

MODE01 MODE02 MODE03

Service

1 0 1

3. Select a command:

PBIT01 PBIT02 PBIT04 PBIT08 PARITY

Locking

0 0 1 0 0

Unlocking

0 0 0 1 0

Next tool CW

1 0 0 0 1

Next tool CCW

0 1 0 0 1

Continuos rotation

CW

1 0 0 0 0

Continuos rotation

CCW

0 1 0 0 0

4. Set

PSTART

for give the confirmation of the movement within 5 s.

(It must stay ON for more than 30 ms).

Locking and unlocking don’t require

PSTART

signal.

The unclamping function keeps the motor enabled, so it is necessary to go in emergency mode and switch

off the three phase supply to safely operate the disc by hand.

The clamping function is active only if the previous operation was the unclamping.

Summary of Contents for DDC4-10-400/20

Page 24: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 24 SERVOMOTOR CABLE ...

Page 25: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 25 DRIVER SUPPLY ...

Page 27: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 27 ...

Page 28: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 28 ...

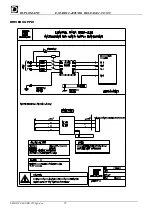

Page 30: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 30 TIME DIAGRAM ...