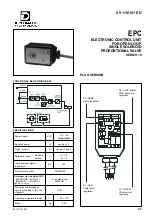

ADJUSTMENTS

Identification P1

P2

P3

P4

code

GAIN RAMP OFFSET SWITCHING

[mA] [mA]

[mA] [mA]

EPC - 110

800

200

EPC - 111 800

100

EPC - 114

800

400

EPC - 120 1200

200

EPC - 130 1600

200

6 - START UP AND CONTROL SETTINGS

If required, settings can be modified as follows:

a) OFFSET CURRENT REGULATION

– Set potentiometer “P1” to minimum.

– Enter the maximum reference signal value (+10V).

– Set potentiometer “P3” so that the valve is positioned at the

start of the work zone.

b) SCALE FACTOR REGULATION

– Enter the maximum reference signal value (+10V).

– Set potentiometer “P1” so that the controlled hydraulic

parameter reaches the maximum required value.

NOTE: The maximum current value must be compatible with

the maximum current prescribed by the technical table of

the connected proportional valve.

c) RAMP REGULATION

– Set potentiometer “P2” to smooth valve response according to

reference signal variations.

EPC

SERIES 10

5 - DEFAULT CONDITIONS

The electronic control unit is supplied factory-set.

Standard settings are:

regulation at

minimum

regulation at

minimum

89 110/101 ED

3/4

3.3 - P3 - OFFSET (Offset current regulation)

Potentiometer “P3” enables regulation of the offset current of the

valve.

This is used to eliminate the valve insensivity zone (dead zone).

The offset current is activated when the reference signal exceeds

the threshold of + 150 mV.

The offset is not active and only the polarization current equal to 25

mA is present beneath this threshold.

NOTE:

The variation of the set value of the offset current causes a

corresponding variation of the scale factor value setted on P1

potentiometer.

Adjustment range = 0

÷

50 % of maximum current

Single turn potentiometer - Rotate clockwise to increase current.

3.4 - P4 - SWITCHING

(PWM frequency regulation)

It is possible to change the switching frequency (PWM) by acting on

the trimmer P4.

The setting range is from 140 to 400 Hz.

An appropriate switching frequency adjustment allows reduction of

the valve hysterisis value.

Single turn potentiometer - Clockwise rotation to increase the

frequency.

NOTE: The potentiometer setting is sealed with a red coating

and it must never be adjusted by the user.

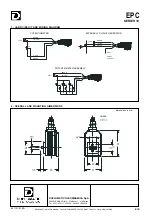

4 - INSTALLATION

The connector type electronic unit is suitable for direct assembly on

the solenoid of the relative proportional valve.

The 4-core connection cable (0,5 mm

2

individual wire section) is

supplied pre-wired and in a standard length of 2,5 m (DIN 47100

standard).

NOTE 1

To observe EMC requirements it is important that the control unit

electrical connection is in compliance with the wiring diagram of par. 7.

As a general rule, the valve and the electronic unit connection wires

must be kept as far as possible from interference sources (e.g.

power wires, electrical motors, inverters and electrical switches).

In environments that are critical from the electromagnetic interference

point of view, a complete protection of the connection wires can be

requested.