IFU . 2

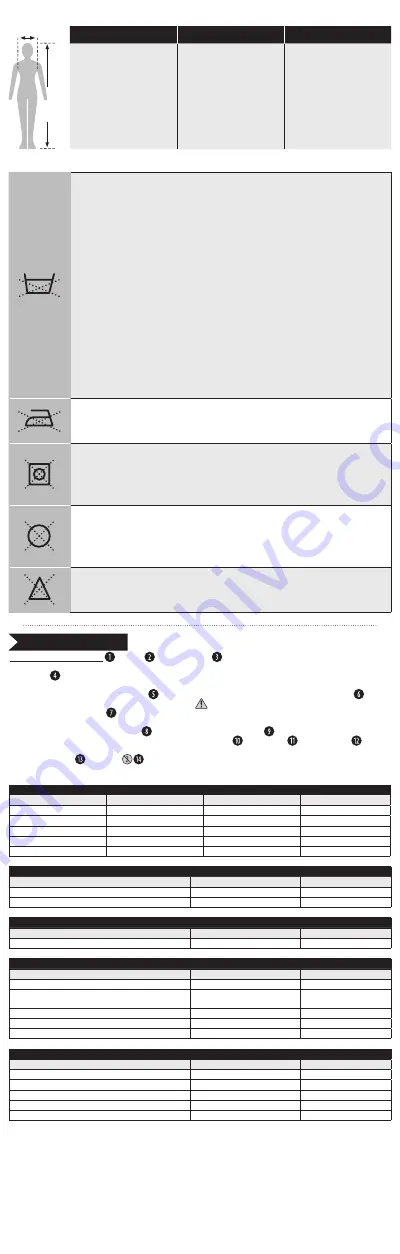

BODY MEASUREMENTS CM

Size

Chest girth

Body height

XS

76 - 84

156 - 164

S

84 - 92

162 - 170

M

92 - 100

168 - 176

L

100 - 108

174 - 182

XL

108 - 116

180 - 188

2XL

116 - 124

186 - 194

3XL

124 - 132

192 - 200

4XL

132-140

200 -208

5XL

140- 148

208 - 216

6XL

148-156

208 - 216

7XL

156-162

208 - 216

THE FIVE CARE PICTOGRAMS INDICATE

Do not wash. Laundering impacts upon protective performance (e. g. antistat will be washed off). • Nicht waschen.

Waschen hat Auswirkungen auf die Schutzleistung (z.B. ist der Schutz gegen statische Aufladung nicht mehr

gewährleistet). • Ne pas laver. Le nettoyage à l’eau altère les performances de protection (le traitement antistatique

disparaît au lavage, par ex.). • Non lavare. Il lavaggio danneggia le caratteristiche protettive (eliminando, ad esempio,

il trattamento antistatico). • No lavar: el lavado afecta a la capacidad de protección (p.ej. pérdida del revestimiento

antiestático). • Não lavar. A lavagem produzirá impactos no desempenho da protecção (ex.: o efeito antiestático

será eliminado). • Niet wassen. Wassen beïnvloedt de beschermende eigenschappen van het kledingstuk

(zo wordt bijvoorbeeld de antistatische laag van de kledingstukken af gewassen). • Tåler ikke vask. Vask påvirker

beskyttelsesegenskapene (f. eks. vil den antistatiske beskyttelsen vaskes bort.). • Må ikke vaskes. Tøjvask påvirker

de beskyttende egenskaber (f. eks. vil den antistatiske behandling blive vasket af). • Får ej tvättas. Tvättning

påverkar skyddsförmågan (antistatbehandlingen tvättas bort). • Ei saa pestä. Peseminen vaikuttaa suojaustehoon

(mm. antistaattisuusaine poistuu pesussa). • Nie prać. Pranie pogarsza właściwości ochronne (np. środek antystatyczny

zostanie usunięty podczas prania). • Ne mossa. A mosás hatással van a ruha védőképességére (pl. az antisztatikus

réteg lemosódik). • Neprat. Praní má dopad na ochranné vlastnosti oděvu (např. smývání antistatické vrstvy). •

Не пери. Машинното пране въздейства върху защитното действие (например антистатикът ще се отмие).

• Neprať. Pranie má vplyv na ochranné vlastnosti odevu (napr. zmývanie antistatickej vrstvy). • Ne prati. Pranje in

likanje negativno učinkujeta na varovalne lastnosti (npr. zaščita pred elektrostatičnim nabojem se spere). • Nu spălaţi.

Spălarea afectează calităţile de protecţie (de ex. protecţia contra electricităţii statice dispare). • Neskalbti. Skalbimas

kenkia apsaugai (pvz., nusiplauna antistatinė apsauga). • Nemazgāt. Mazgāšana var ietekmēt tērpa aizsargfunkcijas.

(piem. var nomazgāt antistata pārklājumu). • Mitte pesta. Pesemine mõjutab kaitseomadusi (nt antistaatik võidakse

välja pesta). • Yıkamayın. Yıkama, koruma performansını etkiler (örneğin antistatik özellik kaybolur). • Μην πλένετε

τη φόρμα. Το πλύσιμο επηρεάζει την παρεχόμενη προστασία (π.χ. η φόρμα θα χάσει τις αντιστατικές της ιδιότητες).

• Ne prati. Pranje utječe na zaštitnu izvedbu (npr. isprat će se antistatičko sredstvo). • Не стирать. Стирка влияет на

защитные характеристики (например, смывается антистатический состав).

Do not iron. • Nicht bügeln. • Ne pas repasser. • Non stirare. • No planchar. • Não passar a ferro. • Niet strijken. • Skal ikke

strykes. • Må ikke stryges. • Får ej strykas. • Ei saa silittää. • Nie prasować. • Ne vasalja. • Nežehlit. • Не глади. • Nežehliť.

• Ne likati. • Nu călcaţi cu fierul de călcat. • Nelyginti. • Negludināt. • Mitte triikida. • Ütülemeyin. • Απαγορεύεται το

σιδέρωμα. • Ne glačati. • Не гладить.

Do not machine dry. • Nicht im Wäschetrockner trocknen. • Ne pas sécher en machine. • Non asciugare nell’asciugatrice.

• No usar secadora. • Não colocar na máquina de secar. • Niet machinaal drogen. • Må ikke tørkes i trommel. • Må ikke

tørretumbles. • Får ej torktumlas. • Ei saa kuivattaa koneellisesti. • Nie suszyć w suszarce. • Ne szárítsa géppel. • Nesušit

v sušičce. • Не суши машинно. • Nesušiť v sušičke. • Ne sušiti v stroju • Nu puneţi în maşina de uscat rufe. • Nedžiovinti

džiovyklėje. • Neveikt automātisko žāvēšanu. • Ärge masinkuivatage. • Kurutma makinesinde kurutmayın. • Απαγορεύεται

η χρήση στεγνωτηρίου. • Ne sušiti u sušilici. • Не подвергать машинной стирке.

Do not dry clean. • Nicht chemisch reinigen. • Ne pas nettoyer à sec. • Non lavare a secco. • No limpiar en seco. • Não

limpar a seco. • Niet chemisch reinigen. • Må ikke renses. • Må ikke kemisk renses. • Får ej kemtvättas. • Ei saa puhdistaa

kemiallisesti. • Nie czyścić chemicznie. • Ne tisztítsa vegyileg. • Nečistit chemicky. • Не почиствай чрез химическо

чистене. • Nečistiť chemicky. • Ne kemično čistiti. • Nu curăţaţi chimic. • Nevalyti cheminiu būdu. • Neveikt ķīmisko

tīrīšanu. • Ärge püüdke puhastada. • Kuru temizleme yapmayın. • Απαγορεύεται το στεγνό καθάρισμα. • Ne čistiti u

kemijskoj čistionici. • Не подвергать химической чистке.

Do not bleach. • Nicht bleichen. • Ne pas utiliser de javel.• Non candeggiare. • No utilizar blanqueador. • Não utilizar

alvejante. • Niet bleken. • Må ikke blekes. • Må ikke bleges. • Får ej blekas. • Ei saa valkaista. • Nie wybielać. • Ne fehérítse.

• Nebělit. • Не избелвай. • Nepoužívať bielidlo. • Ne beliti. • Nu folosiţi înălbitori. • Nebalinti. • Nebalināt. • Ärge

valgendage. • Çamaşır suyu kullanmayın. • Απαγορεύεται η χρήση λευκαντικού. • Ne izbjeljivati. • Не отбеливать.

ENGLISH

INSTRUCTIONS FOR USE

INSIDE LABEL MARKINGS

Trademark. Coverall manufacturer.

Model identification - Tyvek® 600 Plus green model CHA5 is the model

name for a green hooded protective coverall with overtaped seams and cuff, ankle, facial and waist elastication. This instruction for use provides information

on this coverall.

CE marking - Coverall complies with requirements for category III personal protective equipment according to European legislation,

Regulation (EU) 2016/425. Type-examination and quality assurance certificates were issued by SGS Fimko Oy, P.O. Box 30 (Särkiniementie 3), 00211 HELSINKI,

Finland, identified by the EC Notified Body number 0598. Indicates compliance with European standards for chemical protective clothing.

Protection

against particulate radioactive contamination according to EN 1073-2:2002.

EN 1073 -2 clause 4.2. requires resistance to ignition. However resistance to

ignition was not tested on this coverall. Full-body protection “types” achieved by this coverall defined by the European standards for chemical protective

clothing: EN 14605:2005+A1:2009 (Type 4), EN ISO 13982-1:2004+A1:2010 (Type 5) and EN 13034:2005+A1:2009 (Type 6). This coverall also fulfills the

requirements of EN 14126:2003 Type 4-B, 5-B and 6-B.

Wearer should read these instructions for use.

Sizing pictogram indicates body measurements

(cm) & correlation to letter code. Check your body measurements and select the correct size.

Country of origin.

Date of manufacture.

Flammable

material. Keep away from fire. This garment and/or fabric are not flame resistant and should not be used around heat, open flame, sparks or in potentially

flammable environments.

Do not re-use. Other certification(s) information independent of the CE marking and the European notified body.

PERFORMANCE OF THIS COVERALL:

FABRIC PHYSICAL PROPERTIES

Test

Test method

Result

EN Class*

Abrasion resistance

EN 530 Method 2

> 100 cycles

2/6**

Flex cracking resistance

EN ISO 7854 Method B

> 100 000 cycles

6/6**

Trapezoidal tear resistance

EN ISO 9073-4

> 10 N

1/6

Tensile strength

EN ISO 13934-1

> 60 N

2/6

Puncture resistance

EN 863

> 10 N

2/6

* According to EN 14325:2004 ** Visual end point

FABRIC RESISTANCE TO PENETRATION BY LIQUIDS (EN ISO 6530)

Chemical

Penetration index - EN Class*

Repellency index - EN Class*

Sulphuric acid (30%)

3/3

3/3

Sodium hydroxide (10%)

3/3

3/3

* According to EN 14325:2004

FABRIC AND TAPED SEAMS RESISTANCE TO PERMEATION BY LIQUIDS (EN ISO 6529 METHOD A - BREAKTHROUGH TIME AT 1 μg/cm

2

/min)

Chemical

Breakthrough time (min)

EN Class*

Sulphuric acid (18%)

> 60

3/6

* According to EN 14325:2004

FABRIC RESISTANCE TO PENETRATION OF INFECTIVE AGENTS

Test

Test method

EN Class*

Resistance to penetration by blood and body fluids using synthetic blood ISO 16603

3/6

Resistance to penetration by blood-borne pathogenes using

bacteriophage Phi-X174

ISO 16604 Procedure C

no classification

Resistance to penetration by contaminated liquids

EN ISO 22610

1/6

Resistance to penetration by biologically contaminated aerosols

ISO/DIS 22611

1/3

Resistance to penetration by biologically contaminated dust

ISO 22612

1/3

* According to EN 14126:2003

WHOLE SUIT TEST PERFORMANCE

Test method

Test result

EN Class

Type 4: High level spray test (EN ISO 17491-4, Method B)

Pass

N/A

Type 5: Particle aerosol inward leakage test (EN ISO 13982-2)

Pass*** • L

jnm

82/90≤30% • L

s

8/10≤15% **

N/A

Protection factor according to EN 1073-2

> 50

2/3 ***

Type 6: Low level spray test (EN ISO 17491-4, Method A)

Pass

N/A

Seam strength (EN ISO 13935-2)

> 75 N

3/6 *

N/A = Not applicable *According to EN 14325:2004 ** 82/90 means 91,1 % L

jnm

values ≤ 30 % and 8/10 means 80 % L

s

values ≤15 %

***Test performed with taped cuffs, hood and ankles

For further information about the barrier performance, please contact your supplier or DuPont: www.ipp.dupont.com

RISKS AGAINST WHICH THE PRODUCT IS DESIGNED TO PROTECT:

This coverall is designed to protect workers from

hazardous substances, or sensitive products and processes from contamination by people. It is typically used, depending on chemical toxicity and

exposure conditions, for protection against particles (Type 5), limited liquid splashes or sprays (Type 6) or intensive liquid sprays as defined in the Type 4

high level spray test. A full face mask with filter appropriate for the exposure conditions and tightly connected to the hood and additional taping around

the hood, cuffs and ankles are required to achieve the claimed protection. Fabric used for this coverall has been tested according to EN 14126:2003

(protective clothing against infective agents) with the conclusion that the material offers a limited barrier against infective agents (see above table).

LIMITATIONS OF USE

: This garment and/or fabric are not flame resistant and should not be used around heat, open flame, sparks or in potentially

Body

height

Chest girth