D1-1

MECHANICAL ADJUSTMENTS

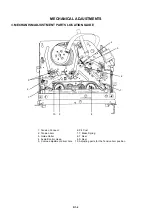

1. CONFIRMATION AND ADJUSTMENT

Read the following NOTES before starting work.

•

•

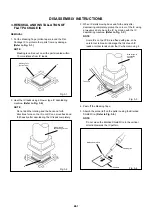

Place an object which weighs between 450g~500g on

the Cassette Tape to keep it steady when you want to

make the tape run without the Cassette Holder. (Do not

place an object which weighs over 500g.)

When you activate the deck without the Cassette

Holder, short circuit between TP1001 and GND. (Refer

to ELECTRICAL ADJUSTMENT PARTS LOCATION

GUIDE) In this condition the BOT/EOT/Reel Sensor will

not function.

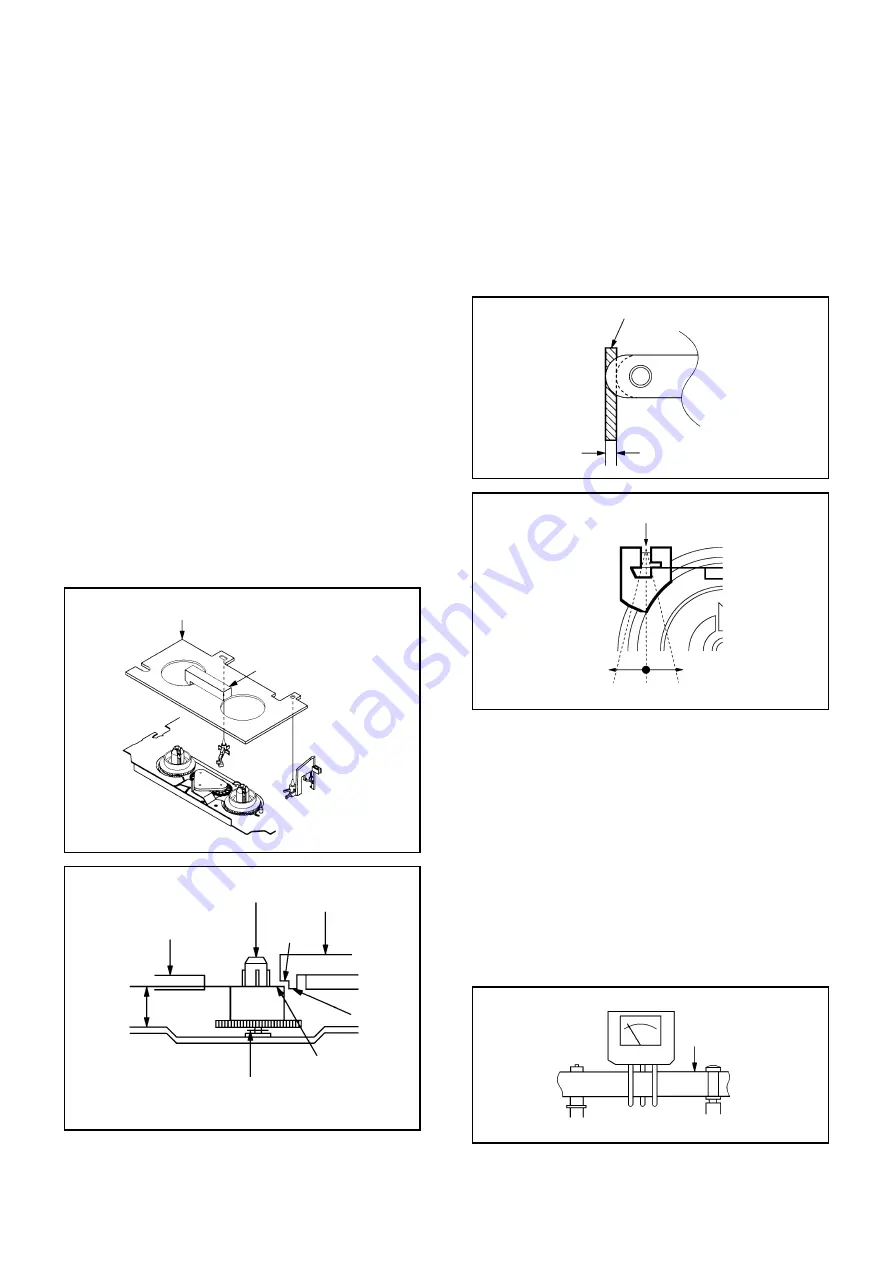

CONFIRMATION AND ADJUSTMENT OF REEL

DISK HEIGHT

1-1:

1.

2.

3.

4.

Turn on the power and set to the STOP mode.

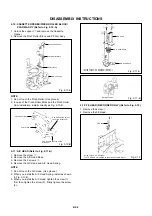

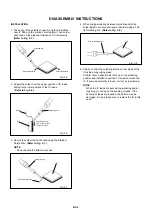

Set the master plane (JG022) and reel disk height

adjustment jig (JG024A) on the mechanism framework,

taking care not to scratch the drum, as shown in Fig. 1-

1-A.

While turning the reel and confirm the following points.

Check if the surface "A" of reel disk is lower than the

surface "B" of reel disk height adjustment jig (JG024A)

and is higher than the surface "C". If it is not passed,

place the height adjustment washers and adjust to

10(+2, -0)mm.

Adjust the other reel in the same way.

Fig. 1-2-B

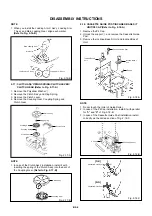

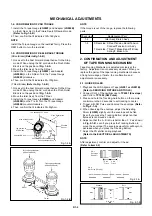

1-3: CONFIRMATION OF PLAYBACK TORQUE AND

BACK TENSION TORQUE DURING PLAYBACK

Load a video tape (T-120) recorded in standard speed

mode. Set the unit to the PLAY mode.

Install the tentelometer as shown in Fig. 1-3. Confirm that

the meter indicates 20

±

2gf in the beginning of playback.

1.

2.

• USING A CASSETTE TYPE TORQUE TAPE (JG100A)

1.

2.

3.

After confirmation and adjustment of Tension Post

position (Refer to item 1-2), load the cassette type

torque tape (JG100A) and set to the PLAY mode.

Confirm that the right meter of the torque tape indicates

50~90gf•cm during playback in SP mode.

Confirm that the left meter of the torque tape indicates

25~40gf•cm during playback in SP mode.

Tentelometer

Video Tape

Guide Roller

P1 Post

Fig. 1-3

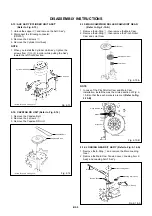

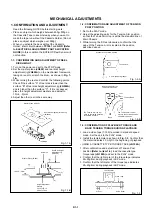

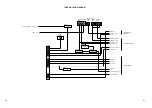

1-2: CONFIRMATION AND ADJUSTMENT OF TENSION

POST POSITION

1.

2.

3.

Set to the PLAY mode.

Adjust the adjusting parts for the Tension Arm position

so that the Tension Arm top is within the standard line of

Main Chassis.

While turning the S Reel clockwise, confirm that the

edge of the Tension Arm is located in the position

described above.

Fig. 1-2-A

Standard line of Main Chassis

Tension Arm

0.5mm (Adjusting range)

Reel Disk Height Adjustment Jig

(JG024A)

Fig. 1-1-A

Reel Disk

Height Adjustment

Washer

2.6x4.7xT0.13

2.6X4.7xT0.25

(B)

(C)

Master Plane (JG022)

Fig. 1-1-B

(A)

10(+0.2, -0)mm

Master Plane (JG022)

Reel Disk Height

Adjustment Jig

(JG024A)

Adjusting parts for the

Tension Arm position

Bend

Tension Band

The Tension Arm top will

move to the outside direction

of the Main Chassis.

The Tension Arm top will

move to the inside direction

of the Main Chassis.