Duracell recommends the charge termination method

described in Section 6.3.1.

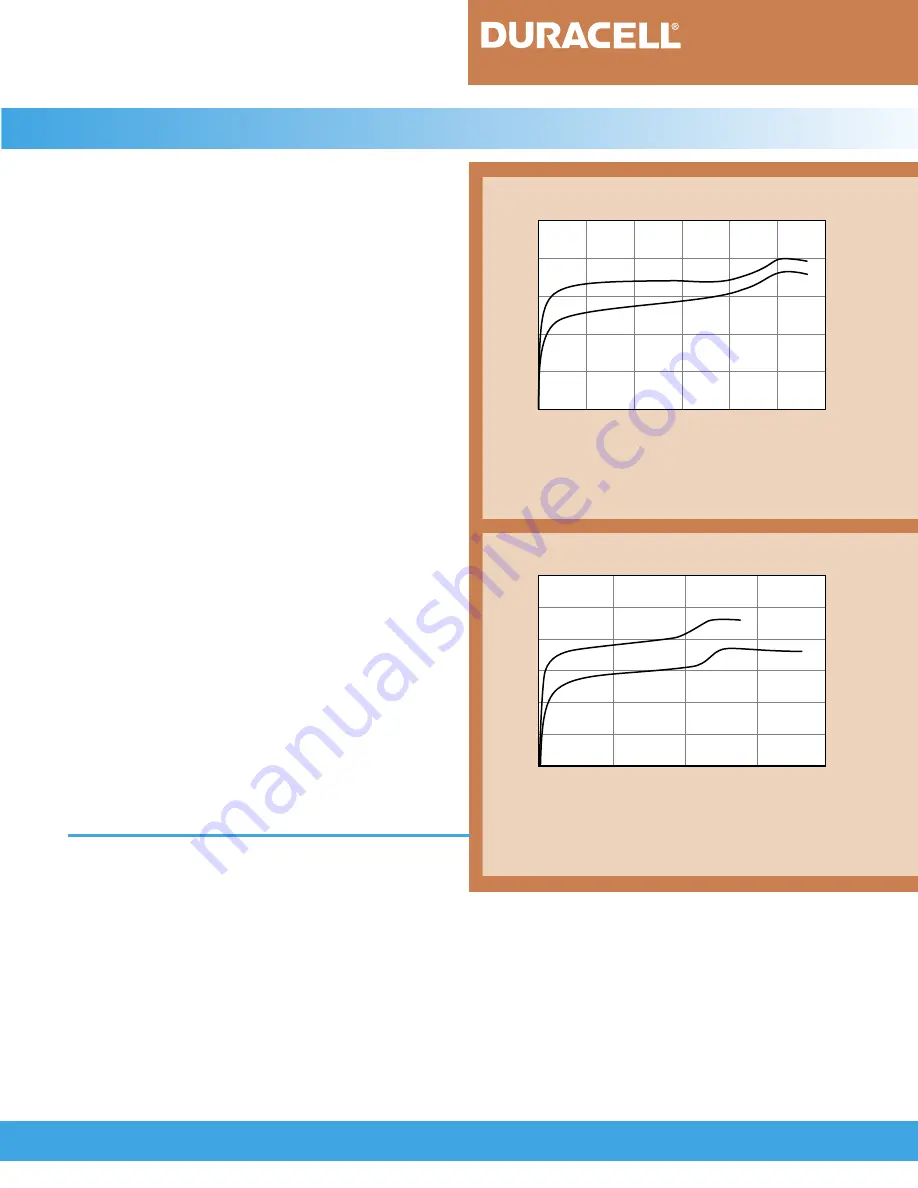

The voltage of the nickel-metal hydride battery

during charge depends on a number of conditions,

including charge current and temperature.

Figures

6.1.3

and

6.1.4

show the voltage profile of the nickel-

metal hydride battery at different ambient temperatures

and charge rates, respectively. The battery voltage rises

with an increase in charge current due to an increase in

the “IR” drop and overpotential during the electrode

reaction. The battery voltage decreases with increasing

temperature as the internal resistance and overpotential

during the electrode reaction decrease.

A rise in temperature and pressure at high

charge rates occurs and underscores the need for prop-

er charge control and effective charge termination

when “fast charging.” Excessive pressure and tempera-

ture increases can result in activation of cell vents or

battery safety electronics, as described in Section 6.4.

Temperature also affects charge efficiency.

Charge efficiency decreases at higher temperatures due

to the increasing evolution of oxygen at the positive

electrode. Thus, charging at high temperatures results

in lower capacity. At lower temperatures, charge effi-

ciency is high due to decreasing oxygen evolution.

However, oxygen recombination is slower at lower tem-

peratures and a rise in internal cell pressure may occur

depending on the charge rate.

Proper charging is critical not only to obtain

maximum capacity on subsequent discharges but also

to avoid high internal temperatures, excessive over-

charge and other conditions which could adversely

affect battery life.

6.2 Techniques for Charge Control

The characteristics of the nickel-metal hydride

battery define the need for proper charge control in

order to terminate the charge and prevent overcharging

or exposure to high temperatures. Each charge control

technique has its advantages and disadvantages. For

example, higher capacity levels are achieved with a 150

percent charge input, but at the expense of cycle life;

long cycle life is attained with a 105 to 110 percent

charge input, albeit with slightly lower capacity due to

less charge input. Thermal cutoff charge control may

reduce cycle life because higher temperatures are

reached during the charge; however, it is useful as a

backup control in the event that the primary termina-

tion method is not effective during charge.

Ni-MH Rechargeable Batteries

12

Charging Sealed Nickel-Metal Hydride Batteries (cont.)

FIGURE 6.1.3

10.0

9.5

9.0

8.5

8.0

7.5

0 0.2 0.4 0.6 0.8 1.0 1.2

Charge Time (Hours)

Voltage (V)

0

°

C (32

°

F)

21

°

C (70

°

F)

Charge voltage of DURACELL DR30 Ni-MH batteries

at various temperatures.

[Conditions: Discharge: C/5 to 6.0V @ 21

°

C (70

°

F); Charge: 1C to -

∆

V =

60mV]

FIGURE 6.1.4

10.0

9.5

9.0

8.5

8.0

7.5

7.0

0

1.0 2.0 3.0 4.0

Charge Capacity (Ah)

Voltage (V)

C (2.4A)

C/5 (0.48A)

Charge voltage of DURACELL DR30 Ni-MH batteries

at various rates.

[Conditions: Discharge: C/5 to 6.0V; Charge: 1C to -

∆

V = 60mV, C/5 to

7.5 hrs.; Temperature: 21

°

C (70

°

F)]