Page

4 D-LX

100

4. Self-Check

The D-LX 100 All-In-One Flame Scanner is fail-safe and self-checking, in accordance with European

EN standards for flame scanning equipment. After power-up, the flame scanner performs a self-

check, which is constantly performed during continuous operation.

If employed for continuous operation, any component failure that jeopardizes the safety-related

functions of a scanner must trigger an error shutdown. The D-LX 100 is therefore equipped with a

dual-channel microprocessor system. This system controls all functions and self-checks, and

monitors all safety-related timing sequences. Input and output status is independently checked and

compared by the microprocessors. Only if they agree is operation allowed to continue.

If the controller signals flame ON, the integrated flame scanner is automatically monitored. This

occurs every second for 0.2 s via the activation of a shutter. The shutter is a transistor separating the

photo element from the electronics. In the case of the D-LX 100 UL, a long-lasting mechanical shutter

is used to interrupt the path from the photo element to the electronics. The interruption of the

photocurrent simulates the outage of a flame and must result in a drop in the flame signal that was

present during the 0.8 s that the scanner was monitoring the flame. If a hardware problem causes too

little a decrease in the flame signal, an error shutdown will occur after eight such cycles, that is, after

eight seconds.

If the flame ON signal is stopped, the integrated flame scanner is also no longer checked.

5. Fault

If the internal self-check recognizes an error in the safety-related software and hardware components,

an error shutdown and internal lockout must be triggered. The relays for the flame, operational

readiness and fault signals are released, and the red LED on the front panel will begin blinking. The

contact from K1 signals the present fault.

The red LED blinks 5 times by itself. After that, the yellow LED will also begin blinking with the red.

The number of times that the yellow LED blinks corresponds to the type of error, which allows the

operator to precisely analyze the source of the fault. The following error sources can be signaled:

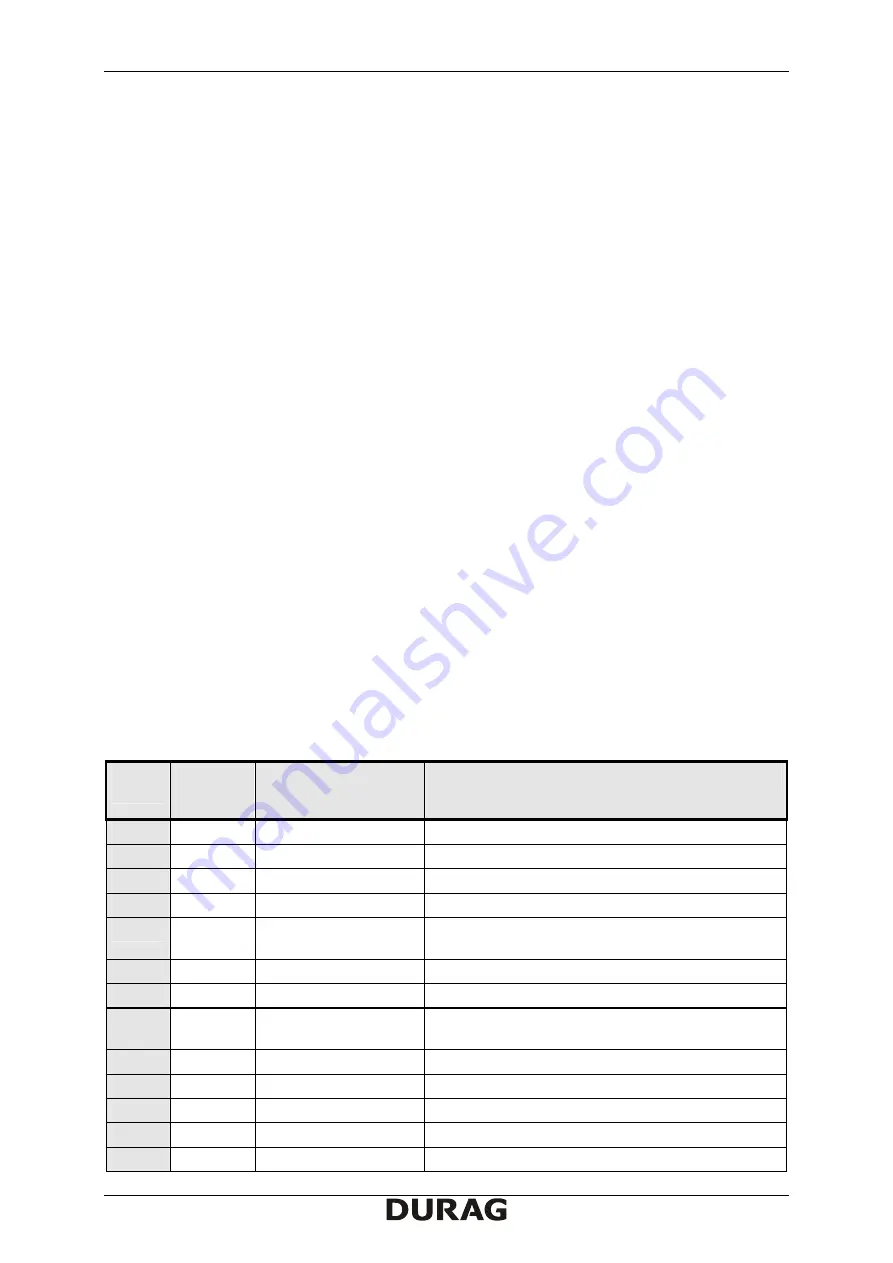

5.1. Error Codes of the 1

st

CPU:

Error

Code

Yellow

LED

Blinks

Source of Error

Possible Cause of the Error

1. 1

x

Synchronization defective

/ faulty microprocessor circuit

2. 2

x

2

nd

CPU

2

nd

CPU is indicating an error (no display of its own)

3.

3 x

FOS cycle

defective cycle generation / faulty acknowledgment

4.

4 x

Flame signal relay

defective drive / faulty acknowledgment

5.

5 x

Flame signal contact

defective / faulty acknowledgment of the contact

position

6.

6 x

Status signal relay

defective drive / faulty acknowledgment

7.

7 x

Flame comparison

faulty transmission of flame data

8.

8 x

Flame recognition

threshold

push button switch on front panel pressed by

unauthorized personnel

9.

9 x

Safety time

unauthorized change in the soldering field

10.

10 x

PROM test

defective / faulty microprocessor circuit

11.

11 x

RAM test

defective / faulty microprocessor circuit

12.

12 x

Flag test

defective / faulty microprocessor circuit

13.

13 x

CPU test

defective / faulty microprocessor circuit