When laying the purge air hoses, ensure the following:

Never use the hose outside of its permissible ambient temperature. Temperature-re-

lated damage can lead to purge air failure.

Do not bend the hoses in too tight a radius in comparison to the hose diameter (risk of

kinking, leading to: purge air failure).

The hoses are not resistant to tension. Do not hang the hoses in free loops under their

own weight. Fit supports at reasonable intervals.

Do not use force, e.g. to drag the hose through excessively narrow openings in walls.

Do not use hoses as attachments or supports for other objects.

Use a hose clamp to attach the hose at the measuring head to the hose connection

(6)

of terminal box D-TB 200.

Item number:

4 016 566

Version number:

10014043-01-Wo

Production date:

15/08/2018

DURAG GmbH

Kollaustraße 105 ∙ 22453 Hamburg, Germany

Tel49 40 55 42 18-0 ∙ info@durag.de

www.durag.com

Maintenance

The D-TB 100 is maintenance-free!

D-TB 200 maintenance work must only be carried out by specialised personnel.

Before disconnecting the purge air supply, if required remove the measuring head

and reflector from the channel/stack. Maintenance intervals are set by the operator

depending on the operating conditions of the D-TB 200. The filter cartridge can be

cleaned several times before it has to be replaced. The maintenance intervals for the

filters depend on the quality of the intake air.

For the maintenance of the filter, proceed as follows:

Open the lock of the filter housing

(9)

.

Remove loose dirt. Clean filter housing and filter (vacuum cleaner).

Insert new or cleaned filter cartridge.

Close filter housing. Make sure that the interlock engages.

Check the door seals of the terminal box. Replace defective seals.

Close the housing door. Switch on the supply voltage.

Check the purge air cables:

Check hoses for damage, kinking and ageing.

Check hose connections for leak-tightness and secure fitting.

Remove deposits from the purge air hoses, taking care not to damage the hose

walls.

Switch on the purge air supply.

If necessary, refit the measuring head and the reflector onto the channel/stack.

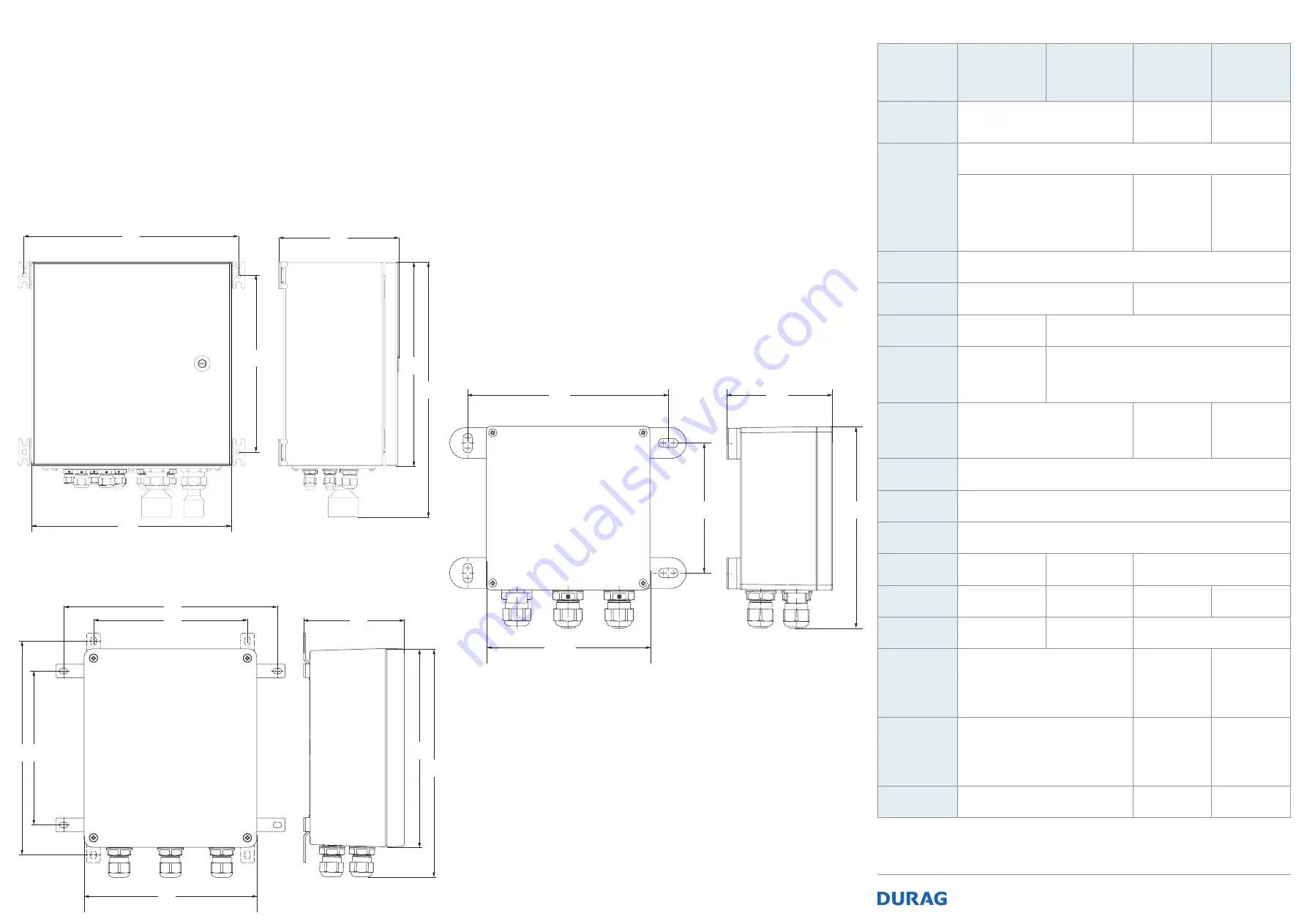

Dimensions

D-TB 200 Ax2-xxxxx-xx

352

430

52

8

239

41

0

D-TB 100 Ax1-

P5DBX-WA

D-TB 100 Ax1-

P5FBX-WA

D-TB 100 Ax2-

MADBX-WB

D-TB 100 Ax2-

MAFBX-WB

D-TB 200 Ax2-

S6MB3-WB

D-TB 200 Ax2-

S6MB1-WB

Mechanical

connections

Not relevant

Purge air

connection

25 mm

Purge air

connection

40 mm

Electrical

connections

Sensor connecting cable with M23

device plug (3, 6 or 12m)

M23 panel jack for measuring head B

(-MAFBX- and -P5FBX- only)

–

for external

purge air

monitoring

and protective

device:

M12 8-pin

Operating

voltage

90 … 264 V~, 48 … 62 Hz

Power

consumption

200 VA

400 VA

Overvoltage

category

–

CAT II

Ambient

temperature

(operation/

storage)

-20 ... +50 °C

-40 … +60 °C

Ambient

temperature

purge air

hoses

Not relevant

Standard:

-25 … +85 °C

Optional:

-40 … +130 °C

Standard:

-20 … +80 °C

Optional:

-40 … +120 °C

Relative

humidity

≤ 95 % relative humidity, non-condensing

IP protection

type

IP65 (EN 60529)

Altitude

≤ 2000 m

Dimensions

160 x 160 x 105 mm

232 x 202 x 116 mm 410 x 400 x 239 mm

Weight

Approx. 2 kg

Approx. 4 kg

Approx. 10 kg

Approx. 12 kg

Material

Polycarbonate,

grey

Aluminium,

coated in blue

Stainless steel,

coated in blue

Purge air

output

None

Stage 1:

max. 15.5 m³/h

(with resistance)

Stage 2:

max. 31 m³/h

Output-

controlled

max. 27 m³/h

Inner

channel pressure

Not relevant

Stage 1:

–50 … +20 hPa

(with resistance)

Stage 2:

+20 … +50 hPa

-50 … +50 hPa

Fan service

life

Not relevant

Stage 1: 40,000 h

Stage 2: 20,000 h

40,000 h

Dimensions

D-TB 100 Ax2-MAxxx-xx

180

18

0

116

23

2

27

0

250

25

0

202

Technical data

Dimensions

D-TB 100 Ax1-P5xxx-xx

400

196

12

7

105

160

19

2