17

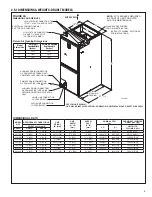

electrical connections. Refrigerant and condensate drain connections are made on

the front of the unit.

• All units require 24 inches minimum access to the front of the unit for service.

• These units may be installed in either ventilated or nonventilated spaces.

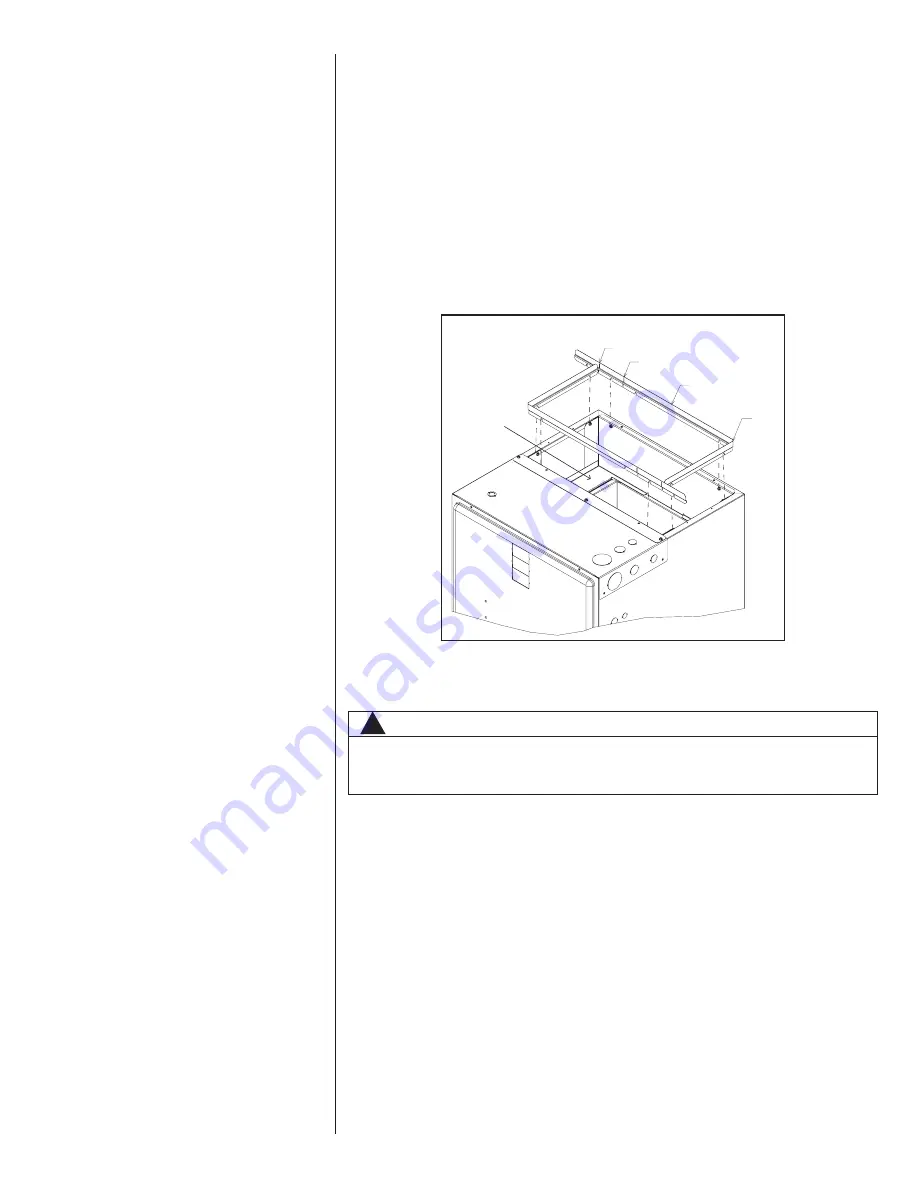

3.5 DUCT FLANGES

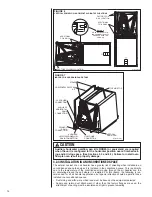

Duct flanges (4 pieces) are shipped with the unit and are to be field installed on the top

of the air-handler using the following procedure and referring to Figure 10.

1.

Loosen the screws attaching the heat barrier to the cabinet.

2. Form a 90° bend with the short leg length at approximately 9.9” from the end where

the slot is cut in the flange to facilitate bending. The duct flanges are shipped sized

for the 24.5” wide cabinet. For the 17.5” and 21” wide cabinets, cut the long leg as

shown in Figure 10 to match the cabinet width.

3. Side the duct flanges onto the screws loosened in step one above. Tighten the

screws to secure the flanges.

3.6 DUCTWORK

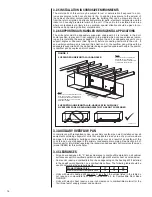

Field ductwork must comply with the National Fire Protection Association NFPA 90A,

NFPA 90B and any applicable local ordinance.

Sheet metal ductwork run in unconditioned spaces must be insulated and covered with a

vapor barrier. Fibrous ductwork may be used if constructed and installed in accordance

with SMACNA Construction Standard on Fibrous Glass Ducts. Ductwork must comply

with National Fire Protection Association as tested by U/L Standard 181 for Class I Air

Ducts. Check local codes for requirements on ductwork and insulation.

• Duct system must be designed within the range of external static pressure the unit is

designed to operate against. It is important that the system airflow be adequate. Make

sure supply and return ductwork, grills, filters, accessories, etc. are accounted for in

total resistance. Refer to the airflow performance tables in this manual to determine the

available external static pressure for the particular air-handler model being installed.

• Design the duct system in accordance with “ACCA” Manual “D” Design for Residential

Winter and Summer Air Conditioning and Equipment Selection. Latest editions are

available from: “ACCA” Air Conditioning Contractors of America, 1513 16th Street,

N.W., Washington, D.C. 20036. If duct system incorporates

flexible air duct,

be sure

pressure drop

information (straight length plus all turns) shown in “ACCA” Manual

“D” is accounted for in system.

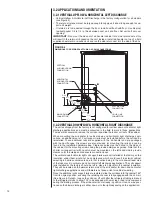

• Supply plenum is attached to the duct flanges supplied with the unit. See Section 3.5.

•

IMPORTANT:

If an elbow is included in the plenum close to the unit, it must not be

smaller than the dimensions of the supply duct flange on the unit.

•

IMPORTANT:

The front flange on the return duct if connected to the blower casing

must not be screwed into the area where the power wiring is located. Drills or sharp

screw points can damage insulation on wires located inside unit.

• Secure the supply and return ductwork to the unit flanges, using proper fasteners for the

type of duct used and tape or caulk the duct-to-unit joint as required to prevent air leaks.

!

WARNING

Do not, under any circumstances, connect return ductwork to any other

heat producing device such as fireplace insert, stove, etc. Unauthorized

use of such devices may result in fire, carbon monoxide poisoning, explo

-

sion, personal injury or property damage.

´&$%,1(7 &87 +(5(

+($7 %$55,(5

´&$%,1(7 &87 +(5(

'8&7 )/$1*(

5(48,5('

%(1'

FIGURE 10

DUCT FLANGE INSTALLATION

• Vertical downflow applications require clearance on at least one side of the unit for