33

1 1 5 0 / 1 1 5 5 H A Y B U S T E R T U B G R I N D E R O P E R A T I N G I N S T R U C T I O N S

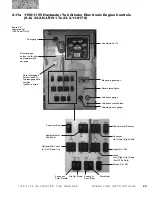

3.9 Operation of the electronic governor

Engine (Auto) mode

IMPORTANT:

Except when calibrating or trouble shooting the electronic governor always use the

engine (auto) mode of the electronic governor.

figure 3.1

electronic governor

controls

sensor light

range switch

engine load

knob

tub speed knob

NOTE: some

units may be

labeled tub limit

control

speed lights

fuse light

In engine (auto) mode, the electronic governor monitors the rotation speed of the engine. The hydraulic flow to the tub

drive mechanism is regulated in proportion to the engine speed. As the engine speed slows, the electronic governor

decreases the hydraulic flow which slows down the tub’s rotation. Conversely, as the engine speed increases, the

electronic governor increases the hydraulic flow which speeds up the tub’s rotation. This allows the electronic governor

to automatically control the feed rate keeping the engine running within the governor’s optimum power zone. When

the load on the grinding rotor begins to lug the engine, the governor automatically reduces the tub’s rotation speed in

proportion to the load. The result is nearly a constant load on the engine, which maximizes the grinding efficiency.

The range of rotor speeds for which the electronic governor will regulate the hydraulic flow is determined by the setting

of the engine load knob. For example, turning the engine load knob counter clockwise will increase the load on the

engine by keeping the tub engaged to a lower engine RPM.

With proper calibration, the engine will only load down to its optimum horsepower RPM, and the tub’s rotation speed

will be varied proportionally to keep the engine at this RPM.

Tub (Manual) mode

In tub (manual) mode, the electronic governor performs as a simple tub speed control. In this mode the tub speed is

constant and it will not change to match varying load conditions.

tub mode

switch

NOTE: some

units may

be labeled

automatic and

manual