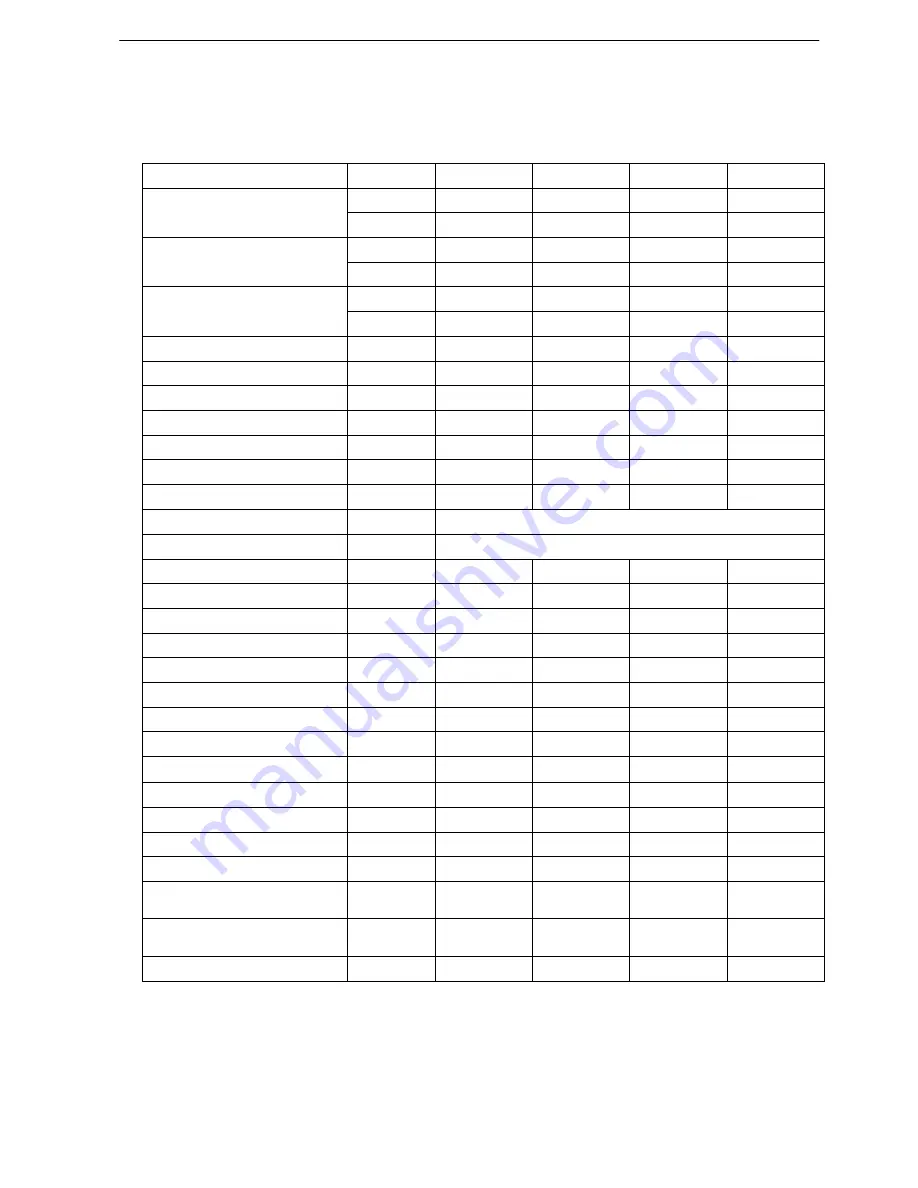

EU heat pumps

4

2. Specifications

2.1 Technical data sheet

Unit

Model

EU 70

EU 100

EU 140

EU 195

kW

7

9,8

14,3

19,6

Heating Capacity A25./W25

BTU/h

23900

33450

48500

66500

kW

6,8

9,5

13,5

18,6

Heating capacity A15/W25

BTU/h

23100

32400

46000

63500

kW

5,2

7,6

12,0

16,4

Cooling capacity A25/W25

BTU/h

17700

26000

41000

56000

Power Input

kW

1,2

1,71

2,46

3,44

Maximum volume

m3

30

40

60

80

Running Current

A

5,22

7,43

10,7

14,96

Max Running Current

A

6,5

9,3

13,4

18,7

COP at A25/W25

5,8

5,7

5,8

5,7

COP at A15/W25

5,3

Power Supply

V/Ph/Hz

220-240/1/50

220-240/1/50

220-240/1/50

220-240/1/50

Controller

Electronic control

Condenser

Titanium heat exchanger

Compressor Quantity

1

1

1

1

Compressor type

rotary

rotary

rotary

Scroll

Refrigerant

R410a

R410a

R410a

R410a

High air flow

M3/h

2100

2100

2300

3200

Low air flow

M3/h

1800

1800

2000

2700

Fan quantity

1

1

1

1

Fan Power Input

W

120

120

120

120

Fan Speed

RPM

850/750

850/750

850/750

850/750

Fan Direction

horizontal

horizontal

horizontal

horizontal

Noise

dB(A)

50

51

54

54

Water Connection

mm

50

50

50

50

Nominal Water Flow

m3/h

3

3

4,5

6,0

Water Pressure Drop (max)

kPa

10

10

10

10

Unit Net Dimensions

L/W/H

mm

905/420/650

905/420/650

905/420/650

1200/470/850

Unit Shipping Dimensions

L/W/H

mm

1030/440/700

1030/440/700

1030/440/700

1240/480/900

Net Weight / Shipping Weight

Kg

55/60

60/65

77/82

117/128

Measuring conditions:

Outdoor air temp: 25°C , Inflowing water temp: 25°C, rel. humidity: 65%