18

The BESTREACH Conveyor is virtually maintenance free. However, we do recommend the follow-

ing:

Keep the conveyor clean and free of debris, dirt and grease accumulation.

Inspect belt for wear and proper tracking.

Make sure photoeyes are clean and unobstructed.

Inspect all bearings for leaking seals or other early signs of failure. (Conveyor belt

rollers and Rear axle pillow blocks)

Check chain tension on the rear axle drive.

Visually inspect floortrack and flexible cable carrier and cables to ensure proper

working order.

Test all EMERGENCY STOP switches to verify proper operation.

Oil in the Motorized Head Pulley is to be monitored and changed per owner’s manual

specification.

All of the above maintenance inspections should be conducted daily.

MAINTENANCE SCHEDULE

FMH Conveyors Operator’s Manual

BestReach Rigid Belt Conveyor

Summary of Contents for FMH BestReach

Page 27: ...26 Assembly Rear Suspension FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

Page 28: ...27 Assembly Front Suspension FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

Page 33: ...32 Decal Group Rigid Belt FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

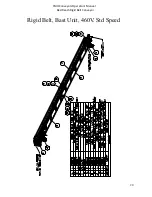

Page 52: ...51 Rigid Belt Schematic STD 480V FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

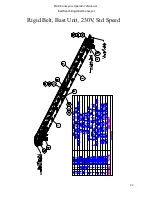

Page 53: ...52 Rigid Belt Schematic STD 240V FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

Page 60: ...59 Wiring Diagram Limit Switch FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

Page 69: ......