7

BELT INSTALATION AND TRACKING:

Unroll the belt, PVC coating side up, around the tail pulley and over the idler rollers. Run belt

over the snub roller and around the drive roll. Align the seam near the center of the conveyor frame.

Pull the belt together to engage the lacing and install the pin. There are two permanent marks in the

center of the belt width approximately 20 feet back from the lacing and 10 feet apart. Find these

marks and take an exact measurement between them. Add .375” (3/8”) to the measurement. Ex-

ample (measured 119 9/16” + 3/8” = 119 15/16). For proper tension, adjust the tail pulley so the

distance between the two marks is equal to the sum of the measured dimension and 3/8”. To insure

the tail pulley is square, be sure both tail pulley blocks are equal distance from the rear of the con-

veyor frame. After tracking the belt, check the dimension between the marks to make sure proper

tension is still in the belt. If the dimension has changed, adjust accordingly and recheck for proper

tracking.

INSTALLATION

(cont)

With the belt installed, begin the tracking procedure. The drive roll should be parallel to the

snub roller. The snub roller should be locked into place. All idler rollers are square to the frame.

Start the belt. Watch to see which side the belt wants to run to and also how quickly it does so. Shut

off the conveyor. Begin belt tracking by adjusting the first idler from the tail. Loosen the bolts on the

idler bracket and angle the roller to correct the belt travel. The roller will steer the belt toward the

uphill side of the roller (Uphill refers to the belt travel direction). If further correction is necessary,

proceed to adjust the first idler from the front, then the two in the center of the conveyor, in that

order. If adjusting the idlers cannot solve the tracking problem, the tail pulley may have to be ad-

justed slightly.

Adjusting the idler rollers will solve most all of the belt tracking problems. The belt should

run straight and on the center of the slider bed. Practice and experience will speed up the belt track-

ing process.

FMH Conveyors Operator’s Manual

BestReach Rigid Belt Conveyor

Summary of Contents for FMH BestReach

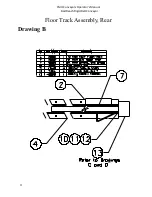

Page 27: ...26 Assembly Rear Suspension FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

Page 28: ...27 Assembly Front Suspension FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

Page 33: ...32 Decal Group Rigid Belt FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

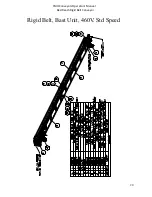

Page 52: ...51 Rigid Belt Schematic STD 480V FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

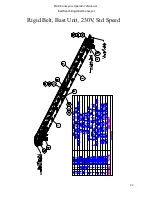

Page 53: ...52 Rigid Belt Schematic STD 240V FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

Page 60: ...59 Wiring Diagram Limit Switch FMH Conveyors Operator s Manual BestReach Rigid Belt Conveyor...

Page 69: ......